Bringing medical devices to the market is a time-consuming and risky challenge. Although DFM approval and clinical trials are essential requirements, they do not guarantee commercial success. Medical device designers can take advantage of rapid manufacturing processes-3D printing, machining and injection molding, including new time-saving developments called “rapid manufacturing.”

Overmolding-Speed up the development cycle, create products that are not only effective but also sensible, aesthetics, and other features that help win market adoption. Medical devices need to be checked at every stage of your development. This is really frustrating because it means you need a lot of prototypes of medical equipment to prove your concept. This article will outline ways to reduce the cost of manufacturing medical devices without compromising the quality and functionality of the prototype. The ultimate goal is to make the manufacturing cost of medical devices lower.

Choose the right material

In the molding process, it is important to choose the right material for each stage of the process. Proof of concept prototypes can be made of cheap materials like plastic or aluminum. Functional medical prototypes, on the other hand, require the same materials to make the final product. This is to ensure that they meet the relevant performance, usability and manufacturability parameters of the final product. Only by using materials that meet the purpose of prototyping can save a lot of money.

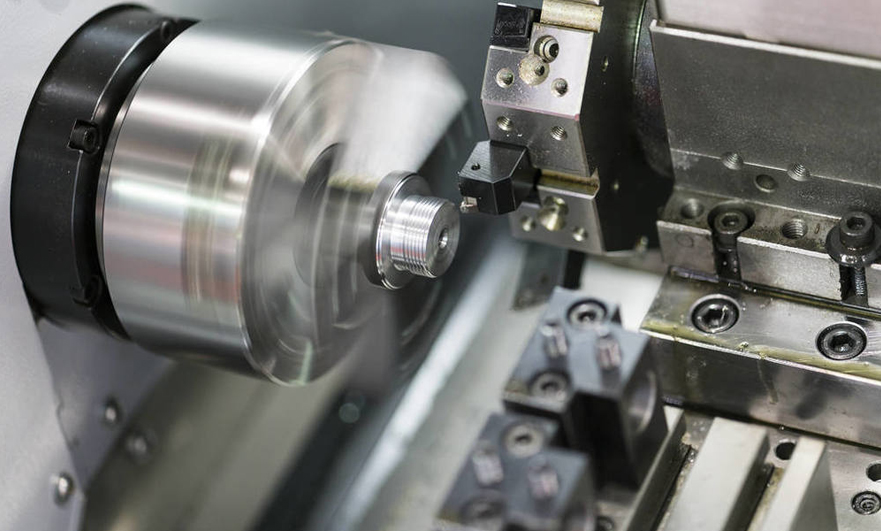

Choose the right machining manufacturing technology

CNC machining is a subtractive manufacturing process, which can produce final-use metal machining parts, and can be well used for forming and assembly testing of parts. The parts produced by high-speed CNC milling come from engineering grade plastics and metals. At the same time, CNC turning works with soft metals and steel.

Use DFM to reduce machining manufacturing costs

There is usually a difference between the actual manufacturing of CNC machined parts and the theoretical validity of the design. It is difficult for design engineers to understand the professional field and manufacturing technology field of CNC machining. This kind of fault greatly hinders the CNC machined parts from meeting the end-use requirements, resulting in the inability to process and manufacture. The correct use of design for manufacturability (DFM) principles can improve the efficiency of medical device manufacturing, and ultimately reduce the cost of medical device manufacturing.

Eliminate functional extensions to achieve economical medical device design

Functional extension refers to all additional items added to the device, but it does not necessarily increase its core design requirements. For aesthetics, extension can adopt additional functions or increase or modify the complexity of parts machining and manufacturing. Although the user functions that can be added require thorough engineering analysis, the extension of manufacturing features requires people with relevant manufacturing experience. They can emphasize which functions will increase the cost of machining and manufacturing, leading to a reduction in the cost of medical device design. The two main factors of tolerance and surface treatment are listed below.

Tolerances-Although parts assembled together without visible part lines may look impressive, they are not always used for functional purposes. Adding too many tolerance requirements to the design can significantly increase manufacturing costs. Restrict strict tolerances to areas that can be justified by engineering necessity.

Surface treatment-For cleaning reasons, the medical field sometimes requires high polishing and mirror treatment. However, not all medical devices need this. Polishing is an expensive operation. Most parts can still work normally when the surface finish is lower than Class A.

Work with prototyping experts

The easiest way to achieve efficient machining and manufacturing of medical devices is to cooperate with experts in the field of medical prototype manufacturing. Many manufacturing plants are happy to process and manufacture parts according to your drawings. These parts will meet specifications, have no manufacturing defects, and will be machined to the nearest micron. However, these manufacturers may not point out ways to reduce manufacturing complexity, because it is not their job to do so.