Optimizing Cutting Force and Power Efficiency in Aluminum CNC Machined Parts

In the world of precision CNC manufacturing, aluminum CNC machined parts play a pivotal role. These components are essential in various industries, from aerospace to automotive, and their quality and performance are of utmost importance. However, achieving the desired results in aluminum CNC machining can be challenging, with cutting force and power consumption being two significant concerns. In this guide, we’ll explore how to address these issues effectively, ensuring that your aluminum CNC machined parts meet the highest standards of quality and efficiency.

Understanding the Importance of Aluminum CNC Machining

Before we delve into optimizing cutting force and power consumption, let’s grasp the significance of aluminum CNC machining. Aluminum is a popular choice for manufacturing due to its lightweight yet durable properties, making it ideal for various applications. However, the quality of CNC machined aluminum parts greatly depends on the precision of the CNC machining process.

Challenges in Aluminum CNC Machining

Aluminum CNC machining involves cutting and shaping aluminum material into specific components. While the process offers unparalleled precision, it also comes with challenges. Two of the most critical challenges are cutting force and power consumption.

Cutting Force: The Driving Factor

Cutting force refers to the force exerted on the tool during machining. In aluminum CNC machining, excessive cutting force can lead to tool wear, surface finish issues, and reduced tool life. It’s essential to manage cutting force effectively to ensure the longevity of tools and the quality of machined parts.

Power Consumption: Efficiency Matters

High power consumption not only impacts operational costs but also affects the overall environmental footprint. Optimizing power efficiency in aluminum CNC machining is not only about saving money but also about sustainability and responsible manufacturing.

Optimizing Cutting Force in Aluminum CNC Machining

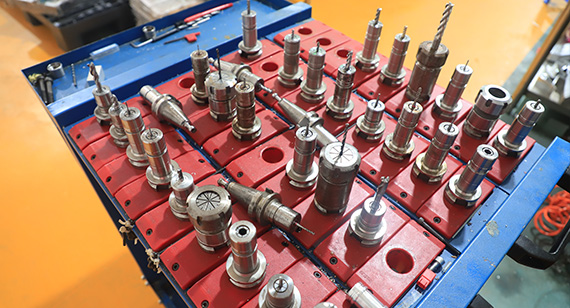

Tool Selection: Choosing the right cutting tools is crucial. High-quality tools designed for aluminum machining can reduce cutting forces significantly.

Cutting Speed and Feed Rate: Adjusting the cutting speed and feed rate appropriately can minimize cutting forces while maintaining machining efficiency.

Coolant and Lubrication: Proper coolant and lubrication techniques reduce friction and, consequently, cutting forces.

Toolpath Optimization: Utilizing advanced CAM software for toolpath optimization can reduce abrupt changes in direction, lowering cutting forces.

Rigorous Tool Maintenance: Regular tool inspection and maintenance are essential to ensure tools are in optimal condition, reducing cutting forces.

Enhancing Power Efficiency in Aluminum CNC Machining

Machine Selection: Investing in energy-efficient CNC machines can significantly reduce power consumption.

Optimized Programming: Well-designed CNC programs can minimize unnecessary movements and tool changes, reducing energy consumption.

Material Handling: Efficient material handling and workpiece setup can contribute to energy savings.

Cutting Fluids: Using the right cutting fluids can reduce friction, leading to lower power consumption.

Monitoring and Data Analysis: Implementing real-time monitoring and data analysis can identify areas of energy wastage and help optimize processes.

The Advantages of Optimization

By effectively managing cutting force and power consumption in aluminum CNC machining, you can enjoy several benefits:

Enhanced Tool Life: Reduced cutting forces lead to less tool wear, extending tool life and lowering replacement costs.

Improved Surface Finish: Lower cutting forces result in smoother surface finishes on machined parts, reducing the need for additional finishing processes.

Cost Savings: Optimizing power efficiency reduces energy costs and operational expenses, contributing to cost savings.

Sustainability: Lower power consumption aligns with sustainability goals and reduces the environmental impact of your manufacturing processes.

Conclusion

Optimizing cutting force and power efficiency in aluminum CNC machining is not only a strategy for improving quality and performance but also a step toward responsible and sustainable manufacturing. By implementing the techniques and strategies discussed in this guide, you can ensure that your aluminum CNC machined parts meet the highest standards of excellence while minimizing costs and environmental impact. Whether you’re a seasoned industry professional or new to CNC machining, these principles are invaluable for achieving success in precision manufacturing.