What is Laser Engraving Logo?

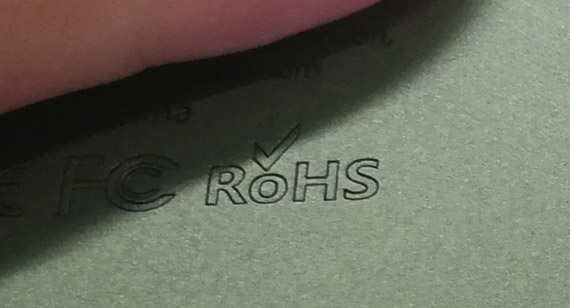

Laser engraving logo is a process that utilizes a laser beam to etch or engrave logos, patterns, or text onto the surface of a material. This process involves the use of laser technology to precisely focus high-energy laser beams onto the surface of the material, thereby permanently altering the characteristics of that surface to create the desired logo or pattern. Laser engraving logos are commonly employed on various materials, including metals, plastics, wood, and more, to achieve high precision and long-lasting logo effects. It finds extensive applications in CNC machining part manufacturing and custom product production, among other fields.

Advantages and disadvantages of laser engraving logo

Advantages of Laser Engraving Logo:

Precision: Laser engraving offers exceptional precision, allowing for intricate and detailed logo designs with fine lines and high-resolution graphics.

Durability: Laser-engraved logos are highly durable and resistant to wear, fading, and damage, ensuring a long-lasting branding solution.

Versatility: It can be used on a wide range of materials, including metal, plastic, wood, glass, and more, providing versatility in logo application.

Speed: Laser engraving is a fast process, making it suitable for high-volume production and quick turnaround times.

Customization: Logos can be easily customized to meet specific design requirements, offering flexibility in branding.

Clean and Precise: Laser engraving produces clean, sharp edges without the need for additional finishing processes.

Contactless: It is a non-contact process, minimizing the risk of material damage or contamination.

Disadvantages of Laser Engraving Logo:

Material Limitations: Not all materials are suitable for laser engraving, and some may produce undesirable results.

Initial Setup Cost: The equipment and software required for laser engraving can be costly, particularly for small businesses.

Limited Color Options: Laser engraving typically produces monochromatic logos, limiting color choices.

Depth Control: Achieving consistent engraving depth on curved or uneven surfaces can be challenging.

Material Removal: Depending on the depth of engraving, some material removal occurs, which may not be suitable for all applications.

Safety Measures: Laser systems require safety precautions to protect operators from laser radiation.

Maintenance: Regular maintenance is necessary to keep the laser equipment functioning optimally.

It’s important to consider these factors when deciding whether laser engraving is the right choice for your specific logo branding needs.

What is an etched logo?

An etched logo refers to a design, pattern, or text that is created on a material’s surface through a chemical or physical process known as etching. Etching involves selectively removing or altering portions of the material’s surface to create the desired logo or design. There are two primary methods of etching:

Chemical Etching: In chemical etching, a mask or stencil is applied to the material’s surface, leaving only the areas intended for etching exposed. The material is then exposed to a chemical solution that selectively corrodes or dissolves the exposed areas, creating the logo or pattern.

Physical Etching: Physical etching, also known as mechanical etching or engraving, involves using mechanical tools or abrasives to physically remove material from the surface. This can be done by hand or with the assistance of machinery.

Etched logos are known for their precision and permanence, making them a popular choice for various applications, including product branding, signage, and decorative elements. The choice between chemical and physical etching depends on factors such as the material, design complexity, and production requirements.

Advantages and Disadvantages of Etching a Logo

Advantages of Etching a Logo:

Precision: Etching allows for high precision and fine detailing, making it suitable for intricate logo designs.

Durability: Etched logos are highly durable and resistant to wear, ensuring long-lasting branding.

Versatility: It can be applied to a wide range of materials, including metal, glass, plastic, and more, providing versatility in logo application.

Customization: Logos can be customized to meet specific design requirements, offering flexibility in branding.

Consistency: Etching produces consistent results, ensuring uniformity in logo appearance.

Permanence: Etched logos are permanent and do not fade or wear off over time.

Professional Appearance: Etching gives logos a professional and polished appearance.

Cost-Effective for Mass Production: It can be cost-effective for high-volume production due to its speed and efficiency.

Disadvantages of Etching a Logo:

Limited Color Options: Etching typically produces monochromatic logos, limiting color choices.

Material Thickness: The depth of etching is limited by the material’s thickness, which can affect design options.

Initial Setup: Some etching methods may require specialized equipment and setup, which can be costly.

Complex Designs: Highly complex designs may be challenging to etch accurately.

Surface Finish: Etching may alter the material’s surface finish, which may or may not be desirable depending on the application.

Material Compatibility: Not all materials are suitable for etching, and some may not produce satisfactory results.

Safety Precautions: Chemical etching processes may require safety measures and proper disposal of chemicals.

When considering etching as a logo branding method, it’s essential to weigh these advantages and disadvantages against your specific needs and preferences to determine if it’s the right choice for your application.

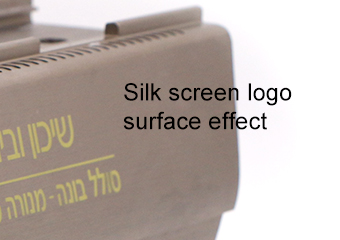

What is a silk screen logo?

A silk screen logo, also known as screen printing or serigraphy, is a branding or decorative technique that involves transferring a design or logo onto a surface using a screen or mesh stencil. Here’s how it works:

Design Preparation: The logo or design to be printed is first prepared as a stencil, typically on a fine mesh screen made of silk, polyester, or other materials. Each color in the design usually requires a separate screen.

Screen Preparation: The screen is coated with a light-sensitive emulsion, which is then exposed to the prepared design. Wherever the emulsion is exposed to light, it hardens, creating a stencil that corresponds to the logo or design.

Ink Application: The screen is placed onto the surface to be printed, such as a T-shirt, paper, plastic, or fabric. Ink is applied to the top of the screen.

Printing Process: A squeegee is used to force the ink through the open areas of the screen, transferring the design onto the surface beneath. Each color is applied one at a time, with the screen being repositioned for accuracy.

Drying: After each color is applied, the printed item is typically dried or cured to set the ink and make it permanent.

Advantages and Disadvantages of Silk Screen Logo

Advantages of Silk Screen Logos:

Versatility: Silk screen printing can be used on various materials, including fabric, paper, plastic, metal, and more.

Durability: The ink used in silk screen printing is typically durable and resistant to fading or washing out.

Cost-Effective for Large Quantities: It’s cost-effective for large production runs, making it suitable for mass branding.

Vibrant Colors: Silk screen printing can achieve vibrant and opaque colors.

Customization: It allows for customization of designs, making it suitable for unique branding needs.

Disadvantages of Silk Screen Logos:

Limited Detail: Fine details and intricate designs may not be reproduced as accurately as other methods.

Multiple Screens: Each color in a design requires a separate screen, which can increase setup costs.

Not Ideal for Small Runs: It may not be cost-effective for small production runs.

Not Suitable for All Materials: Some materials may not be suitable for silk screen printing.

Ink Thickness: The thickness of the ink can affect the texture of the printed surface.

Silk screen logos are commonly used in various applications, including apparel, promotional products, signage, and packaging, where durability and customization are essential considerations.

The difference between laser engraving logo, etching logo and silk screen logo: detailed comparison

Laser Engraving Logo, Etching Logo, and Silk Screen Logo are three distinct methods for applying logos or designs to various surfaces. Here’s a detailed comparison of these techniques:

1. Laser Engraving Logo:

Process: Laser engraving uses a focused laser beam to remove or mark the material’s surface, creating the desired design.

Precision: Extremely high precision, allowing for intricate and detailed logos.

Durability: The engraving is permanent and durable, resistant to fading or wear.

Materials: Suitable for a wide range of materials, including metal, wood, acrylic, glass, and more.

Color Options: Typically, laser engraving results in monochromatic designs, with variations in color based on the material itself.

Cost: Moderate to high, depending on the complexity of the design and material.

2. Etching Logo (Chemical Etching):

Process: Chemical etching involves using chemicals to selectively remove material from the surface, leaving behind the desired logo or design.

Precision: High precision, suitable for fine details and complex designs.

Durability: The etched logo is permanent and resistant to wear and fading.

Materials: Commonly used for metals like stainless steel, brass, and aluminum.

Color Options: Typically, etched logos have a metallic appearance but can be further colored or filled for contrast.

Cost: Moderate, with costs influenced by the material type and complexity of the design.

3. Silk Screen Logo (Screen Printing):

Process: Silk screen printing uses a stencil (screen) to transfer ink onto the material’s surface, creating the logo or design.

Precision: Good precision for simpler designs, but may not achieve the same level of detail as laser engraving or etching.

Durability: Durability can vary depending on the ink used, but it may not be as resistant to wear and fading as engraving or etching.

Materials: Commonly used on various surfaces, including paper, fabric, plastic, and some metals.

Color Options: Offers a wide range of color choices, allowing for multi-color logos.

Cost: Generally lower cost, making it suitable for larger quantities and budget-conscious projects.

Summary:

Laser engraving offers the highest precision and durability but can be more expensive.

Etching provides high precision and durability, mainly on metal surfaces.

Silk screen printing is cost-effective and allows for multi-color designs but may have limitations in precision and durability.

Laser engraving logo vs. etching logo, silk screen logo: Which one is best for you?

Choosing between laser engraving, etching, and silk screen printing for your logo depends on your specific needs and priorities. Here’s a comparison to help you decide which method is best for you:

Laser Engraving Logo:

Best For: Detailed and permanent logos on a variety of materials, including metal, wood, acrylic, and glass.

Pros:

High precision for intricate designs.

Durable and resistant to wear and fading.

Versatile across materials.

Cons:

Moderate to high cost, especially for complex designs.

Monochromatic appearance.

Etching Logo (Chemical Etching):

Best For: Permanent logos on metal surfaces, such as stainless steel, brass, and aluminum.

Pros:

High precision for fine details and complex designs.

Durable and resistant to wear and fading.

Suitable for metal materials.

Cons:

Moderate cost, which can vary depending on material and design complexity.

Limited to metal surfaces.

Silk Screen Logo (Screen Printing):

Best For: Multi-color logos on various surfaces like paper, fabric, plastic, and some metals.

Pros:

Cost-effective for large quantities.

Offers a wide range of color options.

Suitable for various surfaces.

Cons:

Lower precision for intricate designs.

May not be as durable as engraving or etching.

Considerations:

Design Complexity: If your logo has fine details and intricate patterns, laser engraving or etching is preferable.

Material: Consider the surface material. Laser engraving is versatile, while etching is ideal for metals. Silk screen printing is versatile but less durable on some materials.

Budget: Silk screen printing is cost-effective for bulk orders, while engraving and etching are suitable for premium applications with a higher budget.

Durability: If long-lasting durability is critical, laser engraving and etching are better choices than silk screen printing.

Color: If your logo requires vibrant, multi-color printing, silk screen printing is the way to go.

Ultimately, the choice depends on your specific logo, the surface it will be applied to, your budget, and the desired level of precision and durability.

Laser engraving logo, etching logo, silk screen logo: application

Here are the typical applications for laser engraving, etching, and silk screen logo methods:

Laser Engraving Logo:

Metal Products: Laser engraving is commonly used for branding logos on metal products such as stainless steel, aluminum, and brass.

Awards and Trophies: Precise and detailed logos can be engraved onto awards and trophies for a professional finish.

Wood Products: Wooden plaques, signs, and promotional items can feature laser-engraved logos.

Glass and Acrylic: Laser engraving can add logos to glassware, awards, and acrylic items.

Electronics: Logos can be engraved onto electronic devices, gadgets, and components for branding.

Etching Logo (Chemical Etching):

Metal Labels: Etching is popular for creating durable metal labels and nameplates for various industries.

Aerospace: Etched logos are used on aerospace components, providing permanent branding.

Medical Devices: Medical instruments often have etched logos for traceability and identification.

Automotive: Etched logos are common on automotive parts and components.

Consumer Electronics: High-quality logos on electronic devices and gadgets are achieved through etching.

Silk Screen Logo (Screen Printing):

Textiles: Silk screen printing is widely used for applying logos to clothing, bags, and textiles.

Promotional Products: It’s common for promotional items like pens, mugs, and tote bags.

Paper and Packaging: Logos on paper products, packaging, and labels are often done through silk screen printing.

Outdoor Signs: Large outdoor signs and banners often feature silk screen-printed logos.

Custom Apparel: Customized apparel items with vibrant, multi-color logos are a prime application.

Considerations:

Volume: Silk screen printing is ideal for large quantities of promotional items. Laser engraving and etching are suited for lower volumes with a premium look.

Material: The material you’re working with plays a significant role in the choice of method.

Precision: Laser engraving and etching offer high precision, while silk screen printing may have limitations on fine details.

Durability: The durability requirements of your logo should match the chosen application.

Ultimately, the choice of logo application method depends on the materials you’re working with, the desired look, and the intended use of the branded products.

Find a reliable partner to make your choice

Do you know how to choose the right custom logo process for your project? Or if you need an expert who can help you get the most out of these 3 ways, CNCMF CNC machining factory can help.

We provide customized CNC machining services for Peek, polyimide, PTFE, POM, nylon, acrylic, steel, aluminum, titanium, copper and other metal/plastic materials. Whether it is CNC prototyping or low-volume parts production, our team of professional engineers can select the right metal/plastic custom logo for you and meet your needs to a high standard. Then, just upload your CAD files to our email: [email protected] to get a project quote.

Frequently Asked Questions about Laser Engraved Logo, Etched Logo, and Silk Screen Logo

Certainly! Here are some frequently asked questions about laser engraved logos, etched logos, and silk screen logos:

1. What is the main difference between laser engraving and etching logos?

Laser engraving involves physically removing material to create a logo, while etching is a chemical process that corrodes the surface to form the design. Laser engraving is deeper and more permanent.

2. Which method is best for adding logos to metal products?

Laser engraving is a popular choice for metal products due to its durability and precision. It provides a long-lasting logo with a premium look.

3. Can I use silk screen printing for outdoor signage?

Yes, silk screen printing is suitable for outdoor signs and banners. It offers vibrant colors and is cost-effective for large format prints.

4. Which method is best for textiles like t-shirts and bags?

Silk screen printing is commonly used for textiles. It allows for multi-color designs and is flexible for custom apparel.

5. Are laser engraved logos suitable for glassware and acrylic items?

Yes, laser engraving can create precise and permanent logos on glassware and acrylic products. It provides a clean and professional look.

6. Does etching work well for medical device branding?

Yes, etching is often used for medical device branding because it’s durable and can withstand sterilization processes.

7. Can I get detailed and intricate logos with silk screen printing?

Silk screen printing may have limitations with fine details and intricate designs. Laser engraving or etching is better for highly detailed logos.

8. Are there specific materials that are not suitable for silk screen printing?

Silk screen printing is versatile, but it may not adhere well to certain materials like rubber or very soft plastics. Always check material compatibility.

9. Which method is more cost-effective for large quantities of promotional items?

Silk screen printing is often cost-effective for large quantities of promotional items due to its efficiency in high-volume production.

10. Are there any limitations on the size of logos with laser engraving and etching?

Laser engraving and etching can handle logos of various sizes, but extremely large designs may require specialized equipment.

These FAQs should help provide a better understanding of the differences and considerations when choosing the right method for your logo application needs.