Stainless steel is a corrosion-resistant alloy known for its durability and versatility. It is extensively used in CNC machining, aerospace, automotive, medical, and various other industries. The key to harnessing its full potential lies in understanding its alloy grades.

What is Stainless Steel Alloy Grades?

Stainless steel alloy grades are standardized classifications that indicate the composition and properties of a specific stainless steel alloy. These grades help manufacturers and engineers select the most suitable material for a particular application.

The Role of Alloying Elements

Alloying elements are the building blocks of stainless steel grades. Let’s delve into the common elements and their impact on the material’s properties.

Chromium (Cr)

Chromium is the cornerstone of stainless steel’s corrosion resistance. Learn how varying levels of chromium affect the alloy’s performance.

Nickel (Ni)

Nickel enhances stainless steel’s ductility and toughness. Discover how nickel content influences the alloy’s mechanical properties.

Molybdenum (Mo)

Molybdenum adds high-temperature strength to stainless steel. Explore its significance in extreme environments.

Common Stainless Steel Alloy Grades

There are numerous stainless steel grades available, each tailored to specific applications. We’ll spotlight some of the most popular ones.

1. Austenitic Stainless Steel (300 Series)

301 Stainless Steel: The workhorse of CNC machining.

304 Stainless Steel: The go-to choice for kitchen appliances and architectural applications.

316 Stainless Steel: Resistant to corrosion in marine environments.

2. Martensitic Stainless Steel (400 Series)

410 Stainless Steel: Excellent for cutlery and surgical instruments.

420 Stainless Steel: Known for its exceptional hardness.

3. Duplex Stainless Steel

2205 Duplex Stainless Steel: Offers a perfect blend of strength and corrosion resistance.

What are the Stainless Steel Alloy Series Materials?

Stainless steel is a versatile family of materials known for its corrosion resistance and durability. There are several series of stainless steel alloys, each with unique characteristics and applications. Here are some of the main stainless steel series and their common materials:

Austenitic Stainless Steel (300 Series):

304 Stainless Steel: Commonly used for kitchen appliances, architectural applications, and general-purpose usage.

316 Stainless Steel: Known for its excellent corrosion resistance, making it ideal for marine and chemical industries.

321 Stainless Steel: Offers high-temperature resistance, often used in aircraft and automotive parts.

347 Stainless Steel: Similar to 321, with improved high-temperature performance.

Ferritic Stainless Steel (400 Series):

410 Stainless Steel: Used for cutlery, valves, and other applications requiring high strength and hardness.

430 Stainless Steel: Often found in household appliances like refrigerators and dishwashers.

446 Stainless Steel: Known for its high-temperature resistance, suitable for furnace and exhaust system components.

Martensitic Stainless Steel (400 Series):

420 Stainless Steel: Offers good corrosion resistance and high hardness, used in surgical instruments and cutlery.

440 Stainless Steel: Provides excellent hardness and wear resistance, commonly used in knife blades.

Duplex Stainless Steel (200 and 300 Series):

2205 Duplex Stainless Steel: Combines the strength of ferritic steel with the corrosion resistance of austenitic steel. Used in various industries, including chemical processing and oil & gas.

Precipitation-Hardening Stainless Steel (PH Grades):

17-4 PH Stainless Steel: Known for its high strength and corrosion resistance, used in aerospace and medical applications.

Super Duplex Stainless Steel:

2507 Super Duplex Stainless Steel: Offers enhanced corrosion resistance and strength, suitable for offshore and marine applications.

High-Temperature Stainless Steel:

RA330: Designed for high-temperature applications such as industrial heating systems and furnace components.

RA253MA: Offers excellent oxidation resistance and is used in high-temperature exhaust systems.

These are just some of the common stainless steel series and their materials. Each series has specific properties that make it suitable for different applications, so selecting the right stainless steel grade is crucial for the success of a project.

Stainless Steel Alloy Series Materials Advantages

Common stainless steel series materials offer several advantages, making them popular choices in various industries. Here are some of the key advantages of commonly used stainless steel series materials:

Corrosion Resistance:

Austenitic Stainless Steel (300 Series): Known for exceptional corrosion resistance, making it ideal for applications in harsh environments, such as marine and chemical industries.

Strength and Durability:

Martensitic Stainless Steel (400 Series): Offers high strength and hardness, making it suitable for cutlery and surgical instruments.

Duplex Stainless Steel (200 and 300 Series): Combines strength and corrosion resistance, making it suitable for structural and heavy-duty applications.

High-Temperature Resistance:

High-Temperature Stainless Steel: Grades like RA330 and RA253MA are designed to withstand extreme heat, making them suitable for industrial heating systems and furnace components.

Versatility:

Austenitic Stainless Steel (300 Series): Versatile and widely used across industries due to its balance of properties, including corrosion resistance, formability, and weldability.

Duplex Stainless Steel (200 and 300 Series): Offers a combination of strength and corrosion resistance, making it versatile for various applications.

Machinability:

Austenitic Stainless Steel (300 Series): Typically easy to machine, making it a preferred choice for CNC machining.

Ferritic Stainless Steel (400 Series): Offers good machinability, making it suitable for various manufacturing processes.

Hygienic Properties:

Austenitic Stainless Steel (300 Series): Resistant to staining and easy to clean, making it suitable for food processing and medical equipment.

Cost-Effective Options:

Ferritic Stainless Steel (400 Series): Offers cost-effective solutions for applications where high corrosion resistance is not a primary requirement.

Precipitation Hardening:

Precipitation-Hardening Stainless Steel (PH Grades): Allows for the adjustment of mechanical properties through heat treatment, offering versatility in engineering applications.

Creep Resistance:

High-Temperature Stainless Steel: Provides resistance to creep deformation at high temperatures, ensuring long-term structural stability.

Resistance to Scaling and Oxidation:

High-Temperature Stainless Steel: Maintains its integrity in oxidizing and scaling environments, making it suitable for exhaust systems and industrial furnaces.

These advantages make stainless steel series materials a preferred choice for a wide range of applications, from everyday household items to critical components in aerospace, medical, and industrial settings. Selecting the right stainless steel grade depends on the specific requirements of the project, balancing factors like corrosion resistance, strength, and machinability.

Stainless Steel Alloy Series Material Form

Stainless steel alloys exist in various forms to cater to different manufacturing processes and applications. Here are some common forms of stainless steel alloys:

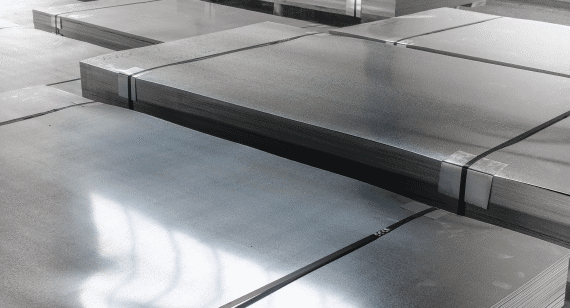

Sheet and Plate:

Stainless steel is often available in thin sheets or thicker plates. These forms are widely used for applications such as kitchen appliances, automotive panels, and architectural elements.

Coil and Strip:

Stainless steel can be produced in coil or strip form, which is ideal for applications requiring continuous rolls of material. This form is commonly used in the manufacturing of tubing, pipes, and electrical components.

Bar and Rod:

Stainless steel is also available in the form of round bars and rods. These are commonly used in construction, machining, and the production of fasteners.

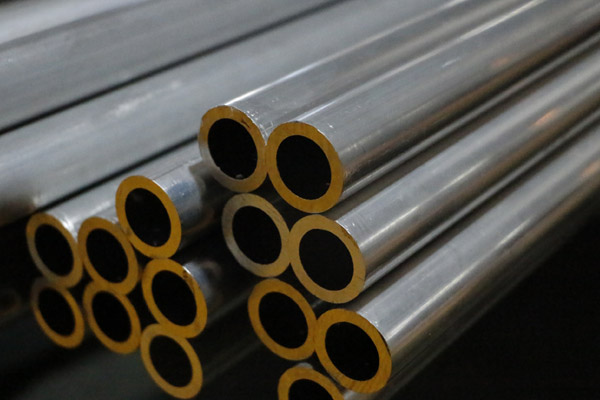

Pipe and Tube:

Stainless steel pipes and tubes are widely used in plumbing, construction, and industrial applications due to their corrosion resistance and durability.

Wire:

Stainless steel wire is utilized in various industries, including aerospace, medical, and electronics. It can be drawn to precise diameters for specific applications.

Fittings and Flanges:

Stainless steel fittings and flanges are essential components in piping systems. They are available in various sizes and configurations to ensure leak-free connections.

Forgings:

Forged stainless steel components are known for their strength and durability. They are commonly used in heavy machinery, automotive, and aerospace applications.

Castings:

Stainless steel can be cast into complex shapes using methods like investment casting. This is beneficial for creating intricate parts in industries such as automotive and industrial equipment.

Powder:

Stainless steel can also be processed into powder form, which is used in additive manufacturing (3D printing) and powder metallurgy processes to create intricate components.

Welding Wire and Electrodes:

Stainless steel welding wire and electrodes are essential for joining stainless steel components. They come in various grades to match the base material and welding process.

Profiles and Structural Shapes:

Stainless steel profiles and structural shapes are used in construction and architectural applications, providing both aesthetic appeal and structural integrity.

Custom Fabrications:

Stainless steel alloys can be custom-fabricated into specific shapes and sizes to meet the unique requirements of various projects. This includes intricate components for the aerospace and medical industries.

These various forms of stainless steel alloys cater to a wide range of industries and applications, offering versatility, corrosion resistance, and durability for different manufacturing needs. The choice of form depends on the specific requirements of the project and the manufacturing process involved.

Stainless Steel Alloy Metal Forming Process

Stainless steel alloys can be shaped and formed using various metal forming processes, each suited to specific applications and desired outcomes. Here are some common metal forming processes for stainless steel alloys:

Sheet Metal Fabrication:

Stainless steel sheets are cut, bent, and welded to create various components and structures. This process is used in industries such as automotive, aerospace, and construction.

Casting:

Stainless steel can be cast using methods like investment casting or sand casting to create intricate and complex shapes. This is often used in the production of components for industrial equipment and machinery.

Forging:

Stainless steel can be forged to improve its mechanical properties and shape. Forging is commonly used to create high-strength components for aerospace, automotive, and industrial applications.

Extrusion:

Extrusion involves forcing stainless steel through a die to create long, uniform profiles and shapes. It is utilized in the production of tubing, pipes, and architectural components.

Cold Working:

Cold working processes like cold rolling, cold drawing, and cold bending are used to reduce the thickness or alter the shape of stainless steel without heating it. Cold working enhances strength and surface finish.

Hot Working:

Hot working involves shaping stainless steel at elevated temperatures. Processes like hot rolling and hot forging are used to produce large components and structural materials.

Welding:

Stainless steel alloys can be welded using various techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and laser welding. Welding is essential for joining stainless steel components in numerous industries.

Deep Drawing:

Deep drawing is used to create intricate and deep-drawn shapes from stainless steel sheets. It’s commonly used in the production of kitchen sinks, automotive parts, and containers.

Spinning:

Spinning is a precision metal forming process used to create cylindrical and conical shapes from stainless steel sheets or blanks. It’s used in the production of items like cookware and lampshades.

Powder Metallurgy:

Stainless steel powder can be compacted and sintered to produce complex shapes, making it useful for applications in the aerospace, automotive, and medical industries.

Additive Manufacturing (3D Printing):

Stainless steel alloys can be used in 3D printing processes, allowing for the creation of intricate and customized components in industries like aerospace and healthcare.

Stamping:

Stainless steel sheets are stamped to create components with specific shapes and features. Stamping is used in the production of electrical connectors, automotive parts, and appliances.

The choice of metal forming process depends on factors such as the desired shape, mechanical properties, cost-effectiveness, and the specific requirements of the application. Stainless steel’s versatility and durability make it suitable for a wide range of metal forming techniques across various industries.

What are the Characteristics of Stainless Steel Alloy Series Materials? Feature Comparison

Certainly, let’s compare common stainless steel alloy series materials based on their formability, machinability, weldability, corrosion resistance, heat treatability, weight, conductivity, thermal conductivity, and applications:

1. Austenitic Stainless Steel (300 Series):

Formability: Excellent, highly formable.

Machinability: Good to excellent.

Weldability: Excellent.

Corrosion Resistance: Excellent, best among stainless steels.

Heat Treatability: Generally not heat-treated.

Weight: Moderate.

Conductivity: Good electrical conductivity.

Thermal Conductivity: Good.

Applications: Versatile, used in kitchen appliances, architectural structures, and chemical processing.

2. Ferritic Stainless Steel (400 Series):

Formability: Good.

Machinability: Good to excellent.

Weldability: Good, may require preheating.

Corrosion Resistance: Moderate, not as resistant as austenitic.

Heat Treatability: Limited.

Weight: Moderate.

Conductivity: Poor electrical conductivity.

Thermal Conductivity: Moderate.

Applications: Used in automotive exhaust systems, household appliances, and decorative trim.

3. Martensitic Stainless Steel (400 Series):

Formability: Fair, hardens when cold worked.

Machinability: Good to excellent.

Weldability: Fair, requires preheating.

Corrosion Resistance: Moderate, not as resistant as austenitic.

Heat Treatability: Excellent for hardening.

Weight: Moderate.

Conductivity: Poor electrical conductivity.

Thermal Conductivity: Moderate.

Applications: Common in cutlery, bearings, and valves.

4. Duplex Stainless Steel (200 and 300 Series):

Formability: Good, less ductile than austenitic.

Machinability: Fair.

Weldability: Good, with care taken to avoid excessive heat input.

Corrosion Resistance: Excellent, especially in corrosive environments.

Heat Treatability: Generally not heat-treated.

Weight: Moderate.

Conductivity: Fair electrical conductivity.

Thermal Conductivity: Moderate.

Applications: Used in chemical processing, oil & gas, and structural components.

5. Precipitation-Hardening Stainless Steel (PH Grades):

Formability: Good.

Machinability: Fair to good.

Weldability: Fair, with proper preheating.

Corrosion Resistance: Good, with precipitation hardening.

Heat Treatability: Excellent for tailored properties.

Weight: Moderate.

Conductivity: Fair electrical conductivity.

Thermal Conductivity: Moderate.

Applications: Ideal for aerospace, medical devices, and high-strength applications.

6. Super Duplex Stainless Steel:

Formability: Fair, less ductile than austenitic.

Machinability: Fair.

Weldability: Good, with care taken to avoid excessive heat input.

Corrosion Resistance: Excellent, especially in aggressive environments.

Heat Treatability: Generally not heat-treated.

Weight: Moderate.

Conductivity: Fair electrical conductivity.

Thermal Conductivity: Moderate.

Applications: Suitable for offshore, marine, and chemical processing.

These comparisons provide insights into the characteristics and applications of various stainless steel alloy series materials, helping you choose the most suitable grade for your specific project requirements.

Stainless Steel Alloy Series Materials Application

Stainless steel alloys find application in a wide range of industries due to their excellent combination of properties, including corrosion resistance, strength, and versatility. Here are some common applications of stainless steel alloy series materials:

Austenitic Stainless Steel (300 Series):

304 Stainless Steel: Used in kitchen appliances, architectural components, and general-purpose applications.

316 Stainless Steel: Common in marine equipment, chemical processing, and medical devices.

321 Stainless Steel: Ideal for aerospace components, automotive parts, and high-temperature applications.

347 Stainless Steel: Similar to 321, with improved high-temperature performance.

Ferritic Stainless Steel (400 Series):

410 Stainless Steel: Found in cutlery, valves, and mechanical components.

430 Stainless Steel: Used in household appliances like refrigerators and dishwashers.

446 Stainless Steel: Suitable for furnace and exhaust system components due to its high-temperature resistance.

Martensitic Stainless Steel (400 Series):

420 Stainless Steel: Common in cutlery, bearings, and surgical instruments.

440 Stainless Steel: Known for its hardness and wear resistance, used in knife blades.

Duplex Stainless Steel (200 and 300 Series):

2205 Duplex Stainless Steel: Ideal for chemical processing, oil & gas, and structural components due to its strength and corrosion resistance.

Precipitation-Hardening Stainless Steel (PH Grades):

17-4 PH Stainless Steel: Used in aerospace, medical devices, and high-strength applications due to its customizable properties.

Super Duplex Stainless Steel:

2507 Super Duplex Stainless Steel: Suitable for offshore, marine, and chemical processing equipment due to its exceptional corrosion resistance.

These applications showcase the versatility of stainless steel alloys, making them crucial materials in various industries such as construction, aerospace, automotive, healthcare, and more. The specific grade of stainless steel chosen depends on the unique requirements of each application, balancing factors like corrosion resistance, mechanical properties, and environmental conditions.

Frequently Asked Questions About Stainless Steel Alloy Series Materials

Certainly, here are some common questions and answers related to stainless steel alloy series materials:

What are the main stainless steel alloy series?

The main stainless steel alloy series include austenitic (300 series), ferritic (400 series), martensitic (400 series), duplex (200 and 300 series), precipitation-hardening (PH grades), and super duplex stainless steel.

What makes austenitic stainless steel (300 series) corrosion-resistant?

Austenitic stainless steel’s corrosion resistance is primarily due to its high chromium content, which forms a protective oxide layer on the surface, preventing further corrosion.

Which stainless steel grade is commonly used in kitchen appliances?

304 stainless steel, from the 300 series, is commonly used in kitchen appliances due to its corrosion resistance and formability.

What is the advantage of using duplex stainless steel (2205) over other grades?

Duplex stainless steel offers a combination of strength and corrosion resistance, making it ideal for applications in chemical processing, oil & gas, and structural components.

Why is precipitation-hardening stainless steel (17-4 PH) suitable for aerospace applications?

17-4 PH stainless steel can be heat-treated to achieve high strength, making it suitable for aerospace components where strength and weight are critical factors.

What applications benefit from super duplex stainless steel (2507)?

Super duplex stainless steel (2507) is used in offshore structures, marine equipment, and chemical processing due to its exceptional corrosion resistance in aggressive environments.

Is stainless steel suitable for high-temperature applications?

Yes, some stainless steel grades, like 321 and 446, are designed for high-temperature applications due to their resistance to oxidation and scaling.

Which stainless steel series has the best formability?

Austenitic stainless steel (300 series) generally offers excellent formability and can be easily shaped into various configurations.

Can stainless steel be welded?

Yes, stainless steel is weldable. However, the welding process may vary depending on the grade, and some grades may require preheating or post-weld heat treatment for optimal results.

What factors should be considered when selecting a stainless steel grade for an application?

When selecting a stainless steel grade, consider factors such as corrosion resistance, mechanical properties, temperature requirements, and the specific environment in which the material will be used.

These questions and answers provide insights into common inquiries about stainless steel alloy series materials, helping individuals and industries make informed choices when selecting the appropriate grade for their applications.