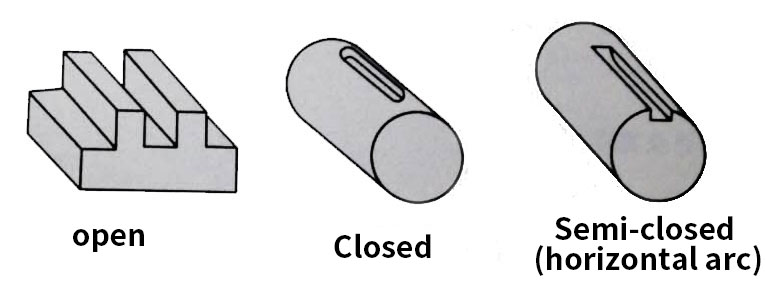

Common right-angle grooves in precision CNC machining parts are open, closed and semi-closed. The end of the semi-closed groove has a vertical milling cutter arc (vertical arc) and a disc milling cutter arc ( Horizontal arc) two forms, the keyway on the shaft is a typical right-angle groove that connects the shaft and the sleeve with a flat key. The special grooves processed on the precision CNC milling machine include V-shaped grooves, T-shaped grooves, and semicircles. Keyway and dovetail groove, etc.

What is right-angle slot milling?

The right-angle groove of precision CNC machining parts is composed of three planes, and its cross-sectional shape is three straight lines, and the adjacent straight lines are perpendicular to each other.

Right-angle grooves are usually divided into three forms: closed, semi-closed and open right-angle grooves. Right-angle grooves can be distributed on flat and cylindrical surfaces. The more classic right-angle grooves are keyways, which can be divided into ordinary flat keyways. And semi-circular keyway.

The characteristics of the right-angle slot milling process are as follows:

1. Use fixed-diameter or fixed-width milling cutters (such as keyway milling cutters, semicircular keyway milling cutters, disc-shaped groove milling cutters, etc.). The control groove width is high precision, such as the shaft of the balance key and the half-round key, the upper key groove, the right-angle groove, and the matching accuracy requirements.

2. In precision CNC machining parts, the symmetrical position of the keyway on the shaft usually adopts different tool setting methods according to the different accuracy levels. The indicator ring table method can be used to adjust the keyway with high symmetrical requirements, so that the relative position of the workpiece axis and the tool axis or the middle section of the disk milling cutter can be aligned. For keyways with low symmetry requirements, the notch tool method can be used for CNC machining.

The keyway processing on the shaft usually adopts V-shaped block positioning, or adopts the indexing head self-centering chuck to clamp, to ensure the symmetry of the parts and other main CNC machining accuracy requirements.

(1) Dimensional accuracy of precision CNC machining parts: The width, length and depth of the groove have certain dimensional accuracy requirements, especially for the parts that match with other parts, the dimensional accuracy requirements are relatively high. For example, because the two sides of the keyway are matched with the flat key, the width tolerance is less than or equal to 0.052mm.

(2) Shape accuracy of precision CNC machined parts: After milling precision CNC machined parts, grooves of various shapes should meet the requirements of precision CNC machined parts pattern shape accuracy. Both right-angle grooves and special-shaped grooves are composed of flat surfaces. Therefore, there are usually basic requirements for flatness and straightness. The planes used for mating have relatively high shape requirements, such as the two sides of the key groove, the two sides of the T-shaped groove reference straight groove, the V-shaped surface of the V-shaped groove, the mating inclined surface and the horizontal plane of the dovetail groove, etc.

(3) Position accuracy of precision CNC machined parts: There is generally a position accuracy requirement between the groove and the reference of the precision CNC machined part. For example, the keyway on the shaft generally has a groove width dimension and the symmetry of the axis of the workpiece. The parallelism requirements of the reference side and the parallelism requirements between several T-shaped grooves. In addition, there are also requirements for equal division accuracy or included angle for the grooves distributed on the shaft-type precision CNC machining parts.

(4) Surface roughness of precision CNC machined parts: there are surface roughness requirements for each surface that composes the groove, and the surface used for matching requires a smaller surface roughness value, such as the two sides of the T-slot reference straight groove on the worktable. It is often used for fixture positioning, so a small surface roughness value is required.