What is Aluminum Fabrication?

Custom aluminum fabrication refers to the intricate process of shaping, manipulating, and assembling aluminum materials into finished products or components. This versatile metal’s lightweight nature, corrosion resistance, and malleability make it a preferred choice for a wide range of applications across industries.

The custom aluminum fabrication process involves several key steps:

Design and Planning:

Fabricators collaborate with engineers and designers to create detailed plans and specifications for the desired product. This step includes selecting the appropriate aluminum alloy and determining the fabrication techniques.

Cutting and Shaping:

Aluminum sheets, bars, or extrusions are cut and shaped into the required forms using various tools such as saws, shears, and CNC machines. Precision is crucial to ensure accurate dimensions.

Bending and Forming:

Aluminum’s malleability allows it to be bent, rolled, or formed into intricate shapes. Hydraulic or mechanical presses are often used to achieve precise angles and curves.

Welding and Joining:

Pieces of aluminum are joined together through techniques like welding, soldering, or adhesive bonding. This step ensures structural integrity and stability.

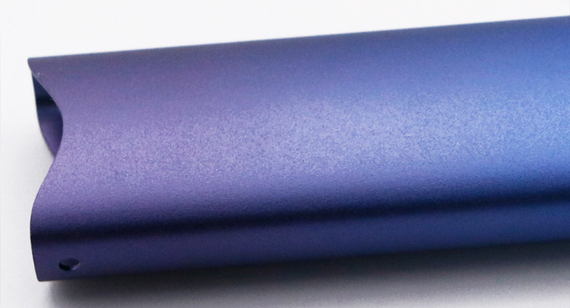

Finishing and Surface Treatment:

Custom aluminum fabrication often involves surface treatments such as polishing, anodizing, powder coating, or painting. These treatments enhance aesthetics, protect against corrosion, and improve wear resistance.

Assembly:

Fabricated aluminum components are assembled to create the final product. This may involve fasteners, rivets, or other methods of secure attachment.

Quality Control:

Rigorous quality checks are conducted throughout the fabrication process to ensure that the final product meets specifications and standards.

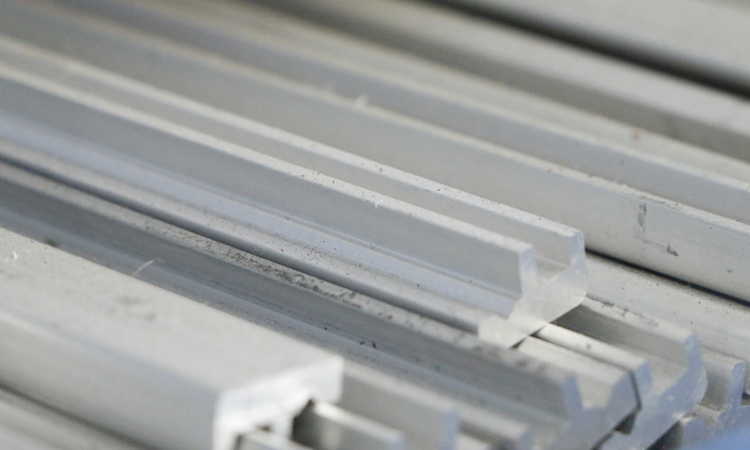

Custom aluminum fabrication Materials Types

Aluminum, a versatile and widely used metal, comes in various forms to cater to diverse manufacturing needs. The different types of aluminum fabrication materials include:

Aluminum Sheets:

Aluminum sheets are flat, thin pieces of aluminum that come in various thicknesses. They are commonly used in industries like construction, automotive, and aerospace for applications such as roofing, panels, and interior components.

Aluminum Rods:

Aluminum rods are cylindrical bars of aluminum that can be round, square, or hexagonal in shape. They are often used in structural applications, such as framework and support structures, due to their strength and versatility.

Aluminum Tubes:

Aluminum tubes are hollow cylinders made from aluminum. They find applications in industries like HVAC, construction, and transportation for conveying liquids, gases, or as structural components.

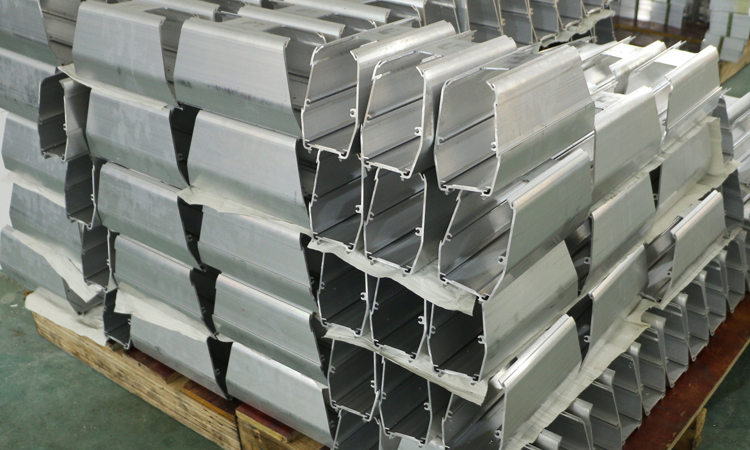

Aluminum Extrusions:

Aluminum extrusions are versatile profiles created by pushing aluminum through a die to achieve specific shapes. These are used in diverse applications, including architectural framing, window systems, and heat sinks.

Aluminum Plates:

Aluminum plates are thicker pieces of aluminum that offer enhanced strength. They are used in applications requiring load-bearing capacity, such as aerospace components, industrial machinery, and marine structures.

Aluminum Foils:

Aluminum foils are thin sheets of aluminum with a thickness less than 0.2mm. They are commonly used in packaging, insulation, and household applications.

Aluminum Profiles:

Aluminum profiles encompass a wide range of shapes and sizes, including angles, channels, and T-sections. These profiles are used for building frames, support structures, and various architectural and industrial applications.

Aluminum Castings:

Aluminum castings are created through casting molten aluminum into molds to achieve complex shapes. They are used in automotive, aerospace, and industrial sectors for parts like engine components and housing.

Each form of aluminum fabrication material serves a specific purpose and offers unique properties. The choice of material depends on factors such as the intended application, required strength, weight considerations, and manufacturing processes. From lightweight construction to heavy-duty industrial applications, the various forms of aluminum fabrication materials provide solutions across a wide spectrum of industries.

Aluminum CNC fabrication Manufacturing Materials: Grades and Series

Aluminum, renowned for its versatility and wide range of applications, offers numerous grades and series suitable for CNC fabrication and manufacturing. Aluminum materials are available in various series, each with its own set of advantages and disadvantages that cater to different applications and requirements. Here’s an overview of the pros and cons of some common aluminum material series:

1000 Series:

The 1000 series is characterized by its high purity, excellent corrosion resistance, and exceptional thermal and electrical conductivity. Commonly used for electrical applications and reflective surfaces.

Advantages: High electrical and thermal conductivity, excellent corrosion resistance, ease of forming and welding.

Disadvantages: Low strength compared to other series, limited application in structural components due to its softness.

2000 Series:

Alloys in the 2000 series are known for their high strength and excellent machinability. They are often used in aerospace and military applications.

Advantages: High strength and toughness, good machinability, suitable for aerospace and military applications.

Disadvantages: Limited corrosion resistance, susceptibility to stress corrosion cracking.

3000 Series:

These alloys possess good formability and corrosion resistance. They find applications in cooking utensils, automotive parts, and chemical equipment.

Advantages: Good formability and corrosion resistance, suitable for cooking utensils and automotive parts.

Disadvantages: Lower strength compared to some other series, not as heat-treatable as others.

5000 Series:

Alloys in the 5000 series exhibit high strength and excellent corrosion resistance. They are often used in marine applications, transportation, and structural components.

Advantages: High strength and excellent corrosion resistance, widely used in marine and structural applications.

Disadvantages: May have reduced formability compared to other series.

6000 Series:

The 6000 series offers a balance of strength, machinability, and formability. It is commonly used for architectural applications, such as window frames and extruded profiles.

Advantages: Good balance of strength, formability, and machinability, commonly used in architectural applications.

Disadvantages: May have slightly lower corrosion resistance compared to other series.

7000 Series:

Known for their high strength-to-weight ratio, alloys in the 7000 series are used in aerospace, defense, and sporting equipment.

Advantages: High strength-to-weight ratio, suitable for aerospace, defense, and sporting equipment.

Disadvantages: May have lower corrosion resistance compared to other series, can be more challenging to machine.

8000 Series:

The 8000 series includes aluminum-lithium alloys with reduced density and improved stiffness. They are primarily used in aerospace applications.

Advantages: Aluminum-lithium alloys offer reduced density and improved stiffness, used in aerospace applications.

Disadvantages: Limited availability and higher cost compared to other series.

These are just a few examples of the many aluminum grades and series available for CNC fabrication and manufacturing. Each grade offers specific characteristics that cater to different requirements, such as strength, corrosion resistance, formability, and machinability. When choosing an aluminum grade for CNC fabrication, it’s essential to consider the intended application, fabrication processes, and desired properties to ensure optimal performance and results.

It’s important to note that the advantages and disadvantages of each aluminum material series depend on the specific alloy within that series. The selection of an aluminum series should align with the intended application’s requirements, such as strength, corrosion resistance, machinability, and thermal properties. Considering these factors will help ensure that the chosen aluminum series delivers optimal performance for the desired application.

How to Manufacture Aluminum Parts?

Manufacturing aluminum parts involves a series of precise steps to transform raw aluminum materials into finished components. Here’s a general overview of the process:

Design and Planning:

Begin by creating detailed plans and specifications for the desired aluminum part. Consider factors like dimensions, tolerances, and material properties.

Material Selection:

Choose the appropriate aluminum alloy based on the part’s requirements. Different alloys offer varying levels of strength, corrosion resistance, and other properties.

Material Preparation:

Obtain aluminum sheets, bars, or extrusions in the required dimensions. If needed, cut or shear the material to the desired size.

CNC Fabrication:

Employ CNC (Computer Numerical Control) machines to precisely shape the aluminum material. This can include processes like milling, turning, drilling, and tapping.

Forming and Bending:

Utilize hydraulic or mechanical presses to bend and shape the aluminum into the desired configuration. This step may involve creating curves, angles, or other intricate shapes.

Welding and Joining:

If necessary, join multiple aluminum parts together using welding, brazing, or adhesive bonding techniques. This ensures structural integrity.

Surface Treatment:

Apply surface treatments such as anodizing, polishing, or painting to enhance the aesthetics, corrosion resistance, and wear resistance of the part.

Assembly:

Assemble the different components of the aluminum part. This may involve fasteners, rivets, or other methods of secure attachment.

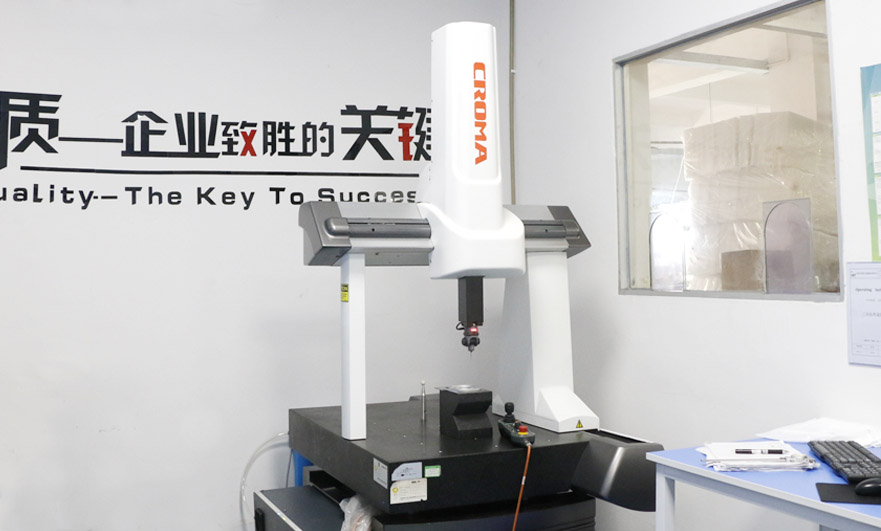

Quality Control:

Perform rigorous quality checks throughout the manufacturing process to ensure that the finished part meets specifications and standards.

Testing and Inspection:

Conduct various tests and inspections to verify the part’s performance, dimensions, and overall quality.

Finishing Touches:

Ensure that the part is free from any defects, burrs, or sharp edges. Package the finished part appropriately for shipping or installation.

Application:

Install the manufactured aluminum part in its intended application, whether it’s a component in machinery, a part of a structure, or part of a larger assembly.

Throughout the manufacturing process, precision, attention to detail, and adherence to industry standards are crucial. The specific steps and techniques used may vary based on the complexity of the part, the chosen aluminum alloy, and the intended application. Regardless of the variation, the goal is to create high-quality aluminum parts that meet the requirements of form, function, and durability.

Aluminum CNC Parts Manufacturing Advantages

Manufacturing aluminum CNC (Computer Numerical Control) parts offers numerous advantages due to the unique properties of aluminum and the precision of CNC fabrication. Here are some key benefits of manufacturing aluminum CNC parts:

Lightweight Design:

Aluminum is known for its lightweight nature, making CNC aluminum parts suitable for applications where weight reduction is crucial, such as aerospace, automotive, and portable devices.

High Strength-to-Weight Ratio:

Aluminum alloys can provide impressive strength while maintaining a relatively low weight, resulting in parts that are both sturdy and efficient.

Corrosion Resistance:

Aluminum naturally forms a protective oxide layer that offers excellent corrosion resistance, ensuring the longevity of CNC aluminum parts even in challenging environments.

Precision and Accuracy:

CNC fabrication allows for exceptional precision and accuracy in creating complex shapes and tight tolerances, ensuring consistent and reliable results.

Wide Range of Finishes:

Aluminum CNC parts can be easily anodized, painted, or powder-coated to enhance their appearance, protect against corrosion, and add to their versatility.

Excellent Machinability:

Aluminum alloys are generally easy to machine, leading to efficient manufacturing processes and shorter lead times for producing parts.

Thermal Conductivity:

Aluminum’s high thermal conductivity makes it suitable for applications that require effective heat dissipation, such as electronic components and heat sinks.

Electrical Conductivity:

Aluminum’s electrical conductivity makes it an ideal choice for parts in electrical systems and applications where conductivity is important.

Recyclability:

Aluminum is highly recyclable, contributing to sustainability efforts and reducing environmental impact.

Versatile Applications:

Aluminum CNC parts find applications across various industries, including aerospace, automotive, electronics, consumer goods, and more.

Cost-Effectiveness:

Aluminum is often more cost-effective than other metals, providing a balance between performance and affordability.

Reduced fabrication Time:

Aluminum’s machinability allows for efficient material removal, leading to reduced fabrication times and cost savings.

Design Flexibility:

Aluminum’s malleability and CNC machining capabilities enable the creation of intricate and innovative designs.

From lightweight aircraft components to intricately designed consumer electronics, aluminum CNC parts offer a multitude of advantages that cater to diverse industry needs. The combination of aluminum’s properties and CNC machining precision ensures the production of high-quality, functional, and reliable parts for a wide range of applications.

Aluminum CNC Machining Parts Limitations

While aluminum CNC (Computer Numerical Control) parts offer a range of advantages, there are also some limitations to consider when utilizing this manufacturing process. Understanding these limitations helps ensure that the chosen material and manufacturing method align with the specific requirements of the application. Here are some key limitations of aluminum CNC parts:

Material Softness:

Some aluminum alloys can be relatively soft, which may limit their suitability for applications requiring high wear resistance or heavy loads.

Lower Strength Than Steel:

While aluminum offers a favorable strength-to-weight ratio, it generally has lower strength compared to steel and some other metals.

Limited High-Temperature Applications:

Aluminum has a lower melting point than many other metals, making it less suitable for applications that involve high temperatures or extreme thermal cycling.

Not Ideal for Very Tight Tolerances:

Achieving extremely tight tolerances may be challenging with some aluminum alloys due to their thermal expansion characteristics.

Susceptibility to Galling:

In certain conditions, aluminum can experience galling, a form of adhesive wear, when in contact with another metal surface under pressure.

Limited Hardness Options:

Some aluminum alloys have limitations in achieving very high levels of hardness, which can affect wear resistance in certain applications.

Electrical Conductivity Variability:

While aluminum is generally a good conductor of electricity, some alloying elements may affect its electrical conductivity.

Surface Finish Considerations:

Achieving certain surface finishes on aluminum CNC parts may require additional post-fabrication steps or specific tooling.

Not Suitable for Magnetic Applications:

Aluminum is not inherently magnetic, which can limit its use in applications that require magnetic properties.

Brittleness at Low Temperatures:

Some aluminum alloys can become brittle at low temperatures, impacting their performance in cryogenic applications.

Complexity of Some Designs:

Intricate and complex designs may pose challenges in terms of fabrication, tool access, and achieving desired tolerances.

Material Cost Variability:

The cost of aluminum alloys can vary based on alloy composition and market conditions, affecting overall project costs.

Environmental Impact:

While aluminum is recyclable, the energy-intensive extraction and refining process may contribute to environmental concerns.

It’s important to note that many of these limitations can be mitigated by careful material selection, design considerations, and appropriate post-fabrication techniques. By understanding the specific requirements of the application and collaborating with experienced manufacturers, it’s possible to leverage the strengths of aluminum CNC parts while addressing any limitations effectively.

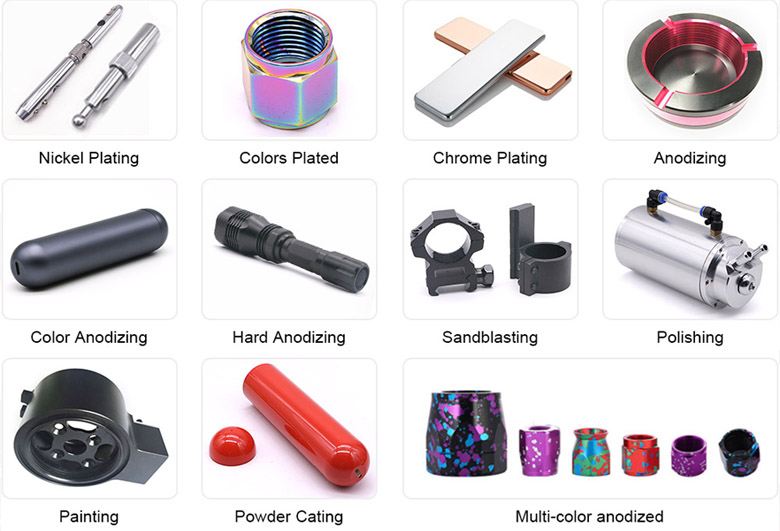

Aluminum CNC Fabrication Parts Surface Treatments

Surface treatments play a crucial role in enhancing the appearance, performance, and durability of aluminum CNC (Computer Numerical Control) parts. Here are some common surface treatments for aluminum CNC parts, categorized by their effects on the surface:

Decorative Surface Treatments:

Anodizing:

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum parts. It provides corrosion resistance, enhances color options, and improves wear resistance.

Powder Coating:

Powder coating involves applying a dry powder paint to the surface of aluminum parts, which is then cured to create a durable and attractive finish with a wide range of color options.

Powder coating can be applied with a gloss finish to create a smooth, glossy surface that enhances aesthetics and provides additional protection.

Powder coating can also be applied with a matte finish to achieve a subdued and sophisticated appearance.

Smooth Surface Effects:

Polishing:

Polishing involves mechanically smoothing the surface of aluminum parts to create a reflective and mirror-like finish, enhancing aesthetics.

Electroplating:

Electroplating deposits a layer of metal, such as chrome or nickel, onto the aluminum surface, providing a lustrous and protective finish.

Satin/Matte Surface Effects:

Sandblasting (Bead Blasting):

Sandblasting uses abrasive particles to create a matte surface with a textured appearance, offering a visually appealing and tactile effect.

Brushed Finish (Satin Finish):

Brushing involves creating fine parallel lines on the aluminum surface, resulting in a consistent and elegant matte finish.

Electrophoretic Deposition (E-Coating or Electropainting):

Electrophoretic deposition applies a thin coat of paint to the surface through an electrochemical process, producing an even and durable matte finish.

Each of these surface treatments offers distinct visual, functional, and protective advantages. The choice of treatment depends on the desired outcome, the application of the part, and the overall aesthetic and performance requirements. Collaborating with experienced manufacturers and surface treatment specialists can help ensure that the chosen treatment aligns with the specific goals of the project.

Aluminum Fabrication Parts Applications

Aluminum machined parts find widespread application across various industries due to their unique combination of properties, including lightweight, durability, and excellent machinability. Here are some key industries and applications where aluminum machined parts are commonly used:

Aerospace:

Aluminum’s lightweight and high strength-to-weight ratio make it a preferred choice for aerospace components such as aircraft frames, wings, landing gear, and interior parts.

Automotive:

Aluminum machined parts are used in automotive applications, including engine components, transmission housings, suspension parts, and body panels, contributing to fuel efficiency and weight reduction.

Electronics and Electrical:

Aluminum parts are used in electronics enclosures, heat sinks, connectors, and housings for electronic devices due to their thermal conductivity and electrical properties.

Consumer Goods:

Aluminum machined parts are found in everyday consumer products such as appliances, kitchenware, furniture frames, and sporting goods due to their aesthetic appeal and corrosion resistance.

Medical Devices:

Aluminum is used in medical devices and equipment, including imaging machines, surgical instruments, and patient monitoring systems, due to its biocompatibility and lightweight nature.

Industrial Machinery:

Aluminum parts are integral to industrial machinery such as conveyors, automation systems, packaging equipment, and manufacturing tools due to their versatility and ease of fabrication.

Renewable Energy:

Aluminum is used in renewable energy applications, including solar panel frames, wind turbine components, and heat exchangers, benefiting from its lightweight and corrosion resistance.

Marine and Shipbuilding:

Aluminum’s corrosion resistance and lightweight properties make it suitable for marine applications such as boat hulls, decks, masts, and marine equipment.

Architecture and Construction:

Aluminum is used in architectural elements like window frames, curtain walls, handrails, and façade panels due to its corrosion resistance, lightweight, and design versatility.

Telecommunications:

Aluminum machined parts are used in telecommunications equipment such as antennas, communication towers, and satellite systems due to their lightweight and durability.

Energy Transmission and Distribution:

Aluminum is utilized in power transmission and distribution systems, including power line towers, due to its lightweight and electrical conductivity.

Defense and Military:

Aluminum is used in military equipment such as vehicle components, aircraft parts, and tactical gear due to its strength, corrosion resistance, and lightweight.

Packaging and Containers:

Aluminum machined parts are used in packaging and container applications due to their durability, ease of forming, and corrosion resistance.

The versatility of aluminum machined parts allows them to meet the demands of diverse industries and applications, contributing to innovation, efficiency, and sustainability in various sectors.

Build your aluminum parts with the experts

Through 13 years of aluminum CNC fabrication parts manufacturing and understanding of applied manufacturing technologies in various industries. CNCMF has the ability to provide you with the best aluminum parts manufacturing services. Whether you need high-volume or low-volume aluminum CNC parts, we can meet your aluminum CNC fabrication manufacturing needs.

Our Aluminum CNC fabrication Parts are served in 62 countries around the world and in every industry sector. We strictly control the quality from the initial engineering review DFM, pre-production, IQC, first article, in-process to final inspection to ensure the quality. We have a professional engineering team to connect with you and tailor project solutions for you , to meet all your CNC fabrication needs.

CNCMF can also provide you with DFM analysis and competitive pricing, contact us now to get 30% discount.