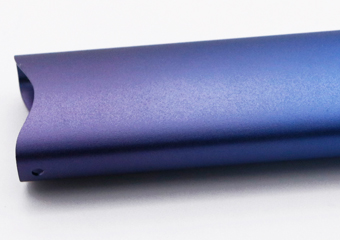

In the world of CNC machining, precision is key. One crucial aspect of achieving precision in metalwork is the process of anodizing. Anodizing not only enhances the appearance of aluminum but also adds durability and corrosion resistance to the material. In this article, we will delve into the fascinating world of multi-color anodizing for aluminum.

What is Anodizing?

Anodizing is an electrochemical process used to enhance the surface of metals, primarily aluminum. It involves creating a protective oxide layer on the metal’s surface by immersing it in an electrolytic bath and passing an electric current through it. This process converts the outer layer of the metal into a more durable, corrosion-resistant, and often aesthetically appealing finish.

What is Multi-Color Anodizing?

Multi-color anodizing is a process that combines multiple colors on the same part. This can include two-color to multi-color parts. The color can be black, transparent, gold, green, blue, red, military green, etc.

Multi-color anodizing is a specialized variation of the anodizing process, primarily applied to aluminum. It involves creating a surface finish with multiple distinct colors on a single aluminum part. This process is achieved through precise control of the anodizing and dyeing stages.

Here’s How Multi-Color Anodizing Works:

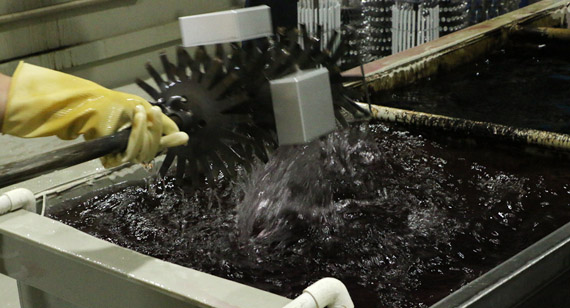

Preparation: Before anodizing, the aluminum surface is meticulously cleaned and prepared to ensure the best results.

Anodizing: The aluminum part is immersed in an anodizing bath, typically containing sulfuric acid, and subjected to an electrical current. This process forms an oxide layer on the aluminum’s surface, which is critical for color absorption.

Dyeing: In multi-color anodizing, different colored dyes are applied to specific areas of the aluminum. This step allows for the creation of various colors on the same part.

Sealing: After dyeing, the part is sealed to lock in the colors and enhance the durability of the finish.

The key to successful multi-color anodizing is precise control over the dyeing process, which can involve masking off sections of the aluminum or using various techniques to achieve intricate and visually appealing color patterns.

This technique is often used in industries where aesthetics and design flexibility are crucial, such as jewelry, decorative pieces, and architectural applications. Multi-color anodizing not only adds vibrant colors to aluminum but also provides the durability and corrosion resistance associated with traditional anodizing.

What is the Purpose of Multi-Color Anodizing?

The primary purpose of multi-color anodizing is to enhance the aesthetic appeal and design flexibility of aluminum products while retaining the benefits of traditional anodizing, such as increased durability and corrosion resistance. Here are the key objectives of multi-color anodizing:

Aesthetic Enhancement: Multi-color anodizing allows for the creation of visually striking and vibrant color patterns on aluminum surfaces. This is particularly valuable in industries where aesthetics play a significant role, such as jewelry, decorative art, and architectural design.

Design Flexibility: Multi-color anodizing offers designers and manufacturers the ability to incorporate intricate and unique color schemes into their products. It provides a wide range of creative possibilities, making it suitable for customized and artistic applications.

Durability: Like traditional anodizing, multi-color anodizing forms a protective oxide layer on the aluminum surface. This layer enhances the material’s durability, making it more resistant to scratches, wear, and corrosion. This is especially important for products intended for outdoor or harsh environments.

Corrosion Resistance: The anodized layer created during multi-color anodizing maintains the inherent corrosion resistance of aluminum. This ensures that even aesthetically pleasing products remain durable and functional over time.

Versatility: Multi-color anodizing can be applied to a wide range of aluminum products, from small decorative items to larger architectural elements. Its versatility makes it suitable for various industries and applications.

In summary, the purpose of multi-color anodizing is to combine the visual appeal of vibrant colors with the protective and functional benefits of traditional anodizing. It opens up new design possibilities and allows for the creation of durable, eye-catching aluminum products.

Multicolor Anodizing: Materials and Industry Applications

Multi-color anodizing is primarily used on aluminum materials. It is a specialized surface treatment technique designed specifically for aluminum due to its unique properties. This process can be applied to various aluminum alloys and forms, including sheets, extrusions, and castings. Some common applications and industries where multi-color anodizing is used on aluminum materials include:

Jewelry: Multi-color anodizing is popular in the jewelry industry for creating vibrant and customized pieces. It allows for intricate and colorful designs on aluminum jewelry items.

Decorative Art: Artists and craftsmen use multi-color anodizing to add artistic and aesthetic appeal to aluminum sculptures, artwork, and decorative pieces.

Architectural Design: In architecture, multi-color anodizing is employed to enhance the appearance of aluminum components used in building facades, interior design elements, and signage.

Consumer Products: Some consumer products, such as electronics casings and sporting goods, may feature multi-color anodized aluminum for both visual appeal and durability.

Automotive Accessories: Multi-color anodizing can be found in automotive accessories, such as custom car parts and trim, to create unique and colorful designs.

Aerospace: While less common, multi-color anodizing can be used in aerospace applications where lightweight, corrosion-resistant materials are needed.

Customized Products: Any industry or application that requires customized and visually appealing aluminum components can benefit from multi-color anodizing.

It’s important to note that multi-color anodizing is not suitable for all materials. It is specifically tailored to aluminum due to the unique properties of aluminum alloys that allow for the formation of a durable and colorful oxide layer during the anodizing process. Other metals may require different surface treatment techniques to achieve similar results.

Multi-Color Anodizing Process

Multi-color anodizing is a specialized surface treatment process applied to aluminum. It involves creating a surface finish with multiple distinct colors on a single aluminum part. Below are the basic steps and the process involved in multi-color anodizing:

1. Surface Preparation:

The first step is to thoroughly clean the aluminum surface to remove any contaminants, oils, or impurities. This ensures that the anodizing process will be successful.

2. Anodizing Bath Preparation:

An electrolytic bath is prepared, typically containing sulfuric acid. The bath serves as the medium through which the anodizing process occurs.

3. Anodizing:

The aluminum part is immersed in the anodizing bath.

An electric current is passed through the bath, with the aluminum part serving as the anode (positive electrode). This process causes the formation of an oxide layer on the surface of the aluminum.

4. Dyeing:

In multi-color anodizing, different colored dyes are applied to specific areas or sections of the aluminum surface. This is where the customization of colors occurs.

The dyes are absorbed into the porous oxide layer created during anodizing.

5. Sealing:

After dyeing, the aluminum part is sealed. Sealing helps lock in the colors and enhances the durability of the finish.

Common sealing methods include hot water sealing or steam sealing.

6. Quality Control:

Quality control checks are performed to ensure that the desired colors and finish have been achieved. This may involve visual inspection and color matching.

7. Additional Processing (Optional):

Depending on the desired design, additional processes such as masking, stenciling, or selective anodizing may be performed to create intricate color patterns.

8. Final Inspection:

A final inspection is conducted to verify that the multi-color anodizing process has been successfully completed and that the aluminum part meets the required quality standards.

The key to achieving the desired multi-color effects in anodizing lies in precise control of the dyeing process. By masking off specific areas, using different dyes, or employing various techniques, intricate and visually appealing color patterns can be created on the aluminum surface.

Multi-color anodizing is commonly used in industries where aesthetics, design flexibility, and customization are essential, such as jewelry, decorative art, and architectural applications. It combines the benefits of anodizing, such as enhanced durability and corrosion resistance, with the ability to add vibrant and unique colors to aluminum products.

Multi-Color Anodizing Processes Types

Multi-color anodizing, also known as multi-color anodization, typically falls into three main types or categories:

Type I Anodizing:

Type I anodizing is a relatively simple form of anodization. It is primarily used for creating a protective oxide layer on the surface of aluminum and does not typically involve coloration. This type is focused on achieving the basic anodized finish with improved corrosion resistance and durability.

Type II Anodizing:

Type II anodizing, also known as decorative anodizing, is the most common method for achieving multi-color effects on aluminum. It allows for the incorporation of various colors into the oxide layer. Type II anodizing is suitable for applications where aesthetics and color customization are essential. It is the process often used in multi-color anodizing.

Type III Anodizing:

Type III anodizing, also known as hardcoat anodizing, is primarily focused on enhancing the hardness and wear resistance of the aluminum surface. While it can be used for coloring, its main purpose is to provide an extremely durable and abrasion-resistant finish. It is less commonly associated with multi-color effects.

What are the Methods of Anodizing and Coloring Metals?

Regarding the methods for coloring during anodization, there are several techniques used in Type II anodizing to achieve multi-color effects:

Dyeing: Different colored dyes are applied to specific areas or sections of the aluminum surface. These dyes are absorbed into the porous oxide layer created during anodization, resulting in the desired colors.

Masking: Masking off specific areas of the aluminum with resist materials before anodizing allows for selective coloring. The masked areas remain uncolored, creating patterns and designs.

Stenciling: Stencils can be used to apply dyes to create precise shapes or designs on the aluminum surface.

Selective Anodizing: This technique involves controlling the anodizing voltage and current to create different oxide layer thicknesses, resulting in variations in color.

Sequential Dyeing: By dyeing the aluminum multiple times with different colors in a specific sequence, a layered or gradient color effect can be achieved.

Each of these methods provides a means to customize and achieve multi-color effects during the anodization process, allowing for a wide range of design possibilities and aesthetics.

What Types of Acids are Used for Color Anodizing?

In anodizing processes, particularly for coloring aluminum, various types of acids are used as electrolytes in the anodizing bath. These acids play a crucial role in the formation of the oxide layer and the absorption of dyes for coloring. Here are some common types of acids used for coloring in anodizing:

Sulfuric Acid (H2SO4): Sulfuric acid is the most commonly used acid in anodizing processes, including multi-color anodizing. It is widely used for Type II anodizing, which is primarily focused on achieving colored finishes. Sulfuric acid anodizing provides good control over oxide layer thickness and is compatible with a wide range of dyes.

Chromic Acid (H2CrO4): Chromic acid anodizing is another method that can be used for coloring aluminum. However, it is less common today due to environmental and safety concerns associated with the use of chromates.

Phosphoric Acid (H3PO4): Phosphoric acid anodizing is primarily used for Type I anodizing, which is focused on providing a basic protective oxide layer. It is not commonly used for coloring purposes but may be employed in specific applications.

Tartaric-Sulfuric Acid: A mixture of sulfuric acid and tartaric acid is used in some specialty anodizing processes, such as architectural anodizing. This combination can produce unique color effects.

Oxalic Acid (H2C2O4): Oxalic acid is occasionally used for anodizing and coloring aluminum. It is known for producing a thinner, more delicate oxide layer compared to sulfuric acid, which can result in distinctive color effects.

Boric-Sulfuric Acid: A mixture of boric acid and sulfuric acid is used in some anodizing processes, particularly for specific industrial applications. This combination can influence the characteristics of the anodized layer.

The choice of acid depends on the specific requirements of the anodizing process, including the desired finish, color range, and environmental considerations. Sulfuric acid remains the most widely used acid for achieving a wide range of colors in multi-color anodizing, while other acids may be used in specialized applications or for unique color effects.

Color Anodizing vs Anodizing: What’s the Difference?

Color Anodizing and Anodizing are two distinct surface treatment processes with notable differences in their purpose and execution:

Purpose:

Anodizing: The primary purpose of anodizing is to create an oxide layer on the surface of metals, typically aluminum. This layer enhances corrosion resistance, hardness, and wear resistance. Anodizing primarily focuses on improving the functional properties of the metal surface.

Color Anodizing: Color anodizing, also known as multi-color anodizing, aims to achieve not only the protective benefits of anodizing but also to add various colors to the metal surface. Its primary goal is to enhance visual appeal and design flexibility.

Color Effects:

Anodizing: Anodizing typically results in a natural silver or light gray oxide layer on the metal surface and does not involve adding colors.

Color Anodizing: The hallmark of color anodizing is its ability to produce a spectrum of different colors on the metal surface. This is achieved through techniques such as dyeing, masking, or stenciling.

Applications:

Anodizing: Anodizing is commonly used in industrial, automotive, aerospace, and other sectors where the focus is on corrosion resistance and functional improvements. It is less concerned with aesthetic appearance.

Color Anodizing: Color anodizing finds applications in fields where visual aesthetics and color customization are crucial. This includes jewelry, decorative arts, architectural design, and custom product manufacturing.

Process Methods:

Anodizing: The anodizing process typically involves immersing the metal in an electrolytic bath and passing an electric current through it to create the oxide layer. Coloring is not a standard part of the process.

Color Anodizing: Color anodizing includes additional steps such as dyeing, masking, engraving, or other techniques to introduce various colors to the metal. These steps are essential to achieving the desired visual effects.

In summary, while anodizing focuses on improving metal properties like corrosion resistance and hardness, color anodizing extends this process to add a diverse range of colors, making it ideal for applications where both functional and aesthetic considerations are important. The choice between the two depends on the specific requirements of the application.

Multi-Color Anodizing Advantages and Disadvantages

Multi-color anodizing, also known as multi-color anodization, offers several advantages and some potential drawbacks, depending on the application and specific requirements. Here are the key advantages and disadvantages of multi-color anodizing:

Advantages:

Aesthetic Versatility: One of the most significant advantages of multi-color anodizing is its ability to add vibrant and customizable colors to aluminum surfaces. This enhances the visual appeal of products and allows for creative design possibilities.

Design Flexibility: Multi-color anodizing provides designers and manufacturers with the flexibility to create intricate and unique color patterns. This is particularly valuable in industries where aesthetics play a crucial role, such as jewelry, decorative art, and architectural design.

Corrosion Resistance: Like standard anodizing, multi-color anodizing retains the inherent corrosion resistance of aluminum. This makes it suitable for both decorative and functional applications, even in outdoor or harsh environments.

Durability: The anodized layer formed during multi-color anodizing is harder than the underlying aluminum, improving scratch and wear resistance. This durability ensures that the colors remain vibrant over time.

Electrical Insulation: Multi-color anodized surfaces can exhibit electrical insulation properties, making them suitable for electronic and electrical applications.

Versatility: Multi-color anodizing can be applied to a wide range of aluminum products, from small decorative items to larger architectural elements. Its versatility makes it valuable across various industries.

Disadvantages:

Complex Process: Multi-color anodizing is a more complex and involved process compared to standard anodizing. It requires additional steps, such as masking, dyeing, and precise control of color application.

Limited Color Range: While multi-color anodizing offers a broad spectrum of colors, achieving specific shades may require experimentation. Certain colors may be more challenging to attain.

Environmental Considerations: Some dyes and chemicals used in the multi-color anodizing process may have environmental implications. Proper disposal and handling of these substances are essential to minimize environmental impact.

Cost: Multi-color anodizing can be more expensive than standard anodizing due to the added steps and customization involved. The cost may vary depending on the complexity of the design.

Specialized Equipment: Implementing multi-color anodizing may require specialized equipment and skilled personnel, which can increase production costs.

In summary, multi-color anodizing is a valuable process for applications where visual aesthetics and design flexibility are paramount. While it offers numerous advantages, including enhanced aesthetics and corrosion resistance, it also involves added complexity, potential environmental considerations, and cost factors that should be carefully considered when selecting this surface treatment method.

Selecting Colors Multi-Color Anodizing Precautions and Tips

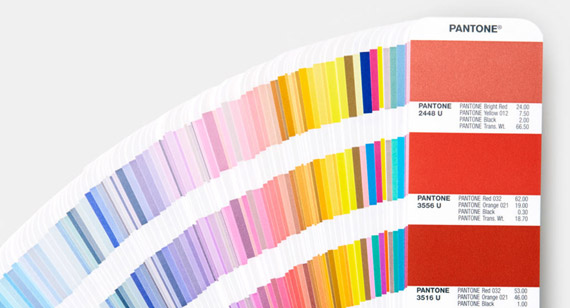

Selecting colors for multi-color anodizing involves a creative process that allows you to achieve the desired visual effects for your aluminum products. Here are some considerations and tips for choosing colors in multi-color anodizing:

1. Design Goals:

Start by defining the design goals for your project. Consider the overall look and feel you want to achieve. Is it a vibrant and bold design, a subtle and elegant one, or something else entirely?

2. Color Palette:

Create a color palette that suits your design objectives. Think about the specific colors you want to incorporate and how they will complement each other. Consider using color theory to guide your choices, such as complementary or analogous color schemes.

3. Brand Identity:

If your project is related to a brand or company, ensure that the chosen colors align with the brand’s identity and message. Consistency in color choices can reinforce brand recognition.

4. Product Functionality:

Consider the intended use of the product. If it’s a functional item, think about how the colors will affect its usability. For decorative pieces, aesthetics may be the primary concern.

5. Audience and Market:

Understand your target audience and the market you’re catering to. Different colors can evoke different emotions and responses, so choose colors that resonate with your audience.

6. Material and Finish:

Take into account the base material (aluminum) and the anodized finish. Some colors may look different on anodized aluminum compared to other materials. Consider how the anodized surface texture will interact with the colors.

7. Test Samples:

Create test samples or prototypes to visualize how the chosen colors will appear on the actual aluminum product. This step allows you to make adjustments if needed.

8. Color Consistency:

Ensure consistency in color application. Multi-color anodizing involves precise control of the dyeing process to achieve the desired shades. Work with experienced professionals to achieve color accuracy.

9. Design Patterns:

Think about the design patterns you want to create. Colors can be used to create gradients, contrasts, or intricate designs. Consider how different colors will interact within the design.

10. Environmental Considerations:

Be mindful of any environmental regulations or concerns related to the dyes and chemicals used in the coloring process. Choose materials and dyes that are eco-friendly if necessary.

11. Cultural and Symbolic Meanings:

Be aware of any cultural or symbolic meanings associated with colors in your target market. Different cultures may interpret colors differently, so research their significance if your product will be sold globally.

Ultimately, the choice of colors in multi-color anodizing should align with your project’s objectives, aesthetics, and the emotional response you want to evoke in your audience. By carefully considering these factors, you can create a visually appealing and meaningful design.

Will Different Aluminum Grade Materials Affect the Color Chromatic Aberration?

Yes, the choice of different aluminum alloy grades can indeed impact the color variation, or color difference, in anodized aluminum. Here’s how:

Chemical Composition: Different aluminum alloy grades have varying chemical compositions, which can affect how the metal reacts during the anodizing process. This reaction plays a crucial role in the final color achieved. Certain alloys may result in slightly different shades or hues when anodized, even when using the same dye and process parameters.

Surface Texture: The surface texture of the aluminum can also influence color variation. Some alloys may have a smoother surface, while others might exhibit variations or imperfections. These surface characteristics can affect how evenly the dye is absorbed and can lead to subtle differences in color.

Thickness of the Oxide Layer: The thickness of the oxide layer formed during anodizing can vary based on the alloy’s composition. Thicker or thinner oxide layers can impact how light interacts with the surface, potentially resulting in differences in color perception.

Base Color: The natural color of the aluminum alloy before anodizing can influence the final color achieved. For example, some alloys have a slightly yellowish or reddish tint, which can affect the appearance of certain dye colors.

Anodizing Process: The specific anodizing process parameters, such as voltage, current density, and anodizing time, may need to be adjusted for different aluminum alloys to achieve consistent color results. This is because each alloy responds differently to the anodizing process.

To minimize color variation, especially in multi-color anodizing where consistency is crucial, it’s essential to carefully select and test the aluminum alloy for compatibility with the desired colors. Working with experienced professionals who are familiar with the characteristics of various alloys and the anodizing process can help ensure more predictable and consistent color results.

If the Color of an Anodized Part does not Match, How do I Remove the Color?

If the color on anodized aluminum parts does not match the desired or intended color, it can be challenging to remove the color without damaging the underlying anodized layer. However, there are some methods you can consider:

Chemical Stripping:

Chemical stripping involves using a chemical solution to remove the anodized layer, including any colorants. This process can be effective but should be done carefully to avoid damaging the aluminum substrate. It may also require re-anodizing and coloring the part afterward.

Mechanical Abrasion:

Light mechanical abrasion using abrasive pads or sandpaper may help remove some surface color, but this method is typically limited and may not work for deep color penetration. Be cautious to avoid excessive abrasion, which can damage the anodized layer.

Polishing:

Polishing the surface with a suitable abrasive compound or aluminum polish may help reduce color variations, especially if the color issue is due to surface staining or contaminants. Polishing should be done gently to avoid removing too much of the anodized layer.

Re-Anodizing:

In cases where the color discrepancy is significant and cannot be resolved by other means, re-anodizing the part may be necessary. This involves stripping the existing anodized layer and applying a new one with the desired color. It should be performed by a professional anodizing service.

Consult an Expert:

If you encounter color matching issues with anodized aluminum parts, it’s advisable to consult with an experienced anodizing specialist or a professional anodizing service. They can assess the situation, recommend the most appropriate solution, and perform any necessary rework to achieve the desired color.

Keep in mind that removing color from anodized aluminum can be challenging, and the success of these methods depends on the extent of the coloration and the thickness of the anodized layer. It’s essential to exercise caution to prevent damage to the underlying substrate. Preventing color mismatches in the first place through careful color selection, process control, and testing is often the best approach.

Difficulties and Precautions in Multi-Color Anodizing

Multi-color anodizing, also known as multi-color anodization, can be a complex process with various challenges and considerations. Here are some of the key challenges and precautions to keep in mind:

Challenges:

Color Consistency: Achieving consistent and repeatable colors across multiple parts can be challenging. Variations in alloy composition, surface preparation, and anodizing parameters can lead to color differences.

Dye Penetration: Ensuring that dyes penetrate uniformly across the entire surface and thickness of the anodized layer can be difficult. Inconsistent dye penetration can result in uneven colors.

Masking Precision: Masking or stenciling is often used to create intricate color patterns. Achieving precise and clean masked areas requires skill and attention to detail.

Color Matching: Matching specific colors accurately can be challenging, as different alloys and processing conditions may yield variations in hue or shade.

Environmental Considerations: Some dyes and chemicals used in the coloring process may have environmental implications. Proper disposal and handling are crucial to minimize environmental impact.

Precautions and Considerations:

Material Selection: Choose the appropriate aluminum alloy for your application, considering how it reacts to the anodizing and coloring processes. Some alloys may produce more consistent colors than others.

Surface Preparation: Properly clean and prepare the aluminum surface before anodizing to ensure uniform color absorption and adhesion.

Dye Selection: Carefully choose dyes that are compatible with the anodizing process and are known for their stability and consistency.

Controlled Environment: Maintain consistent environmental conditions, such as temperature and humidity, to minimize variations in the anodizing and dyeing processes.

Process Control: Monitor and control anodizing parameters, such as voltage, current density, and anodizing time, to achieve consistent results.

Dyeing Process: Implement precise and controlled dyeing processes to ensure even color distribution. Adjust dye concentrations and immersion times as needed.

Quality Control: Implement rigorous quality control measures, including visual inspections and color matching, to identify and address color discrepancies early in the process.

Testing and Prototyping: Create test samples or prototypes to verify the desired colors and patterns before proceeding with full-scale production.

Expertise: Work with experienced professionals who specialize in multi-color anodizing. Their expertise can help overcome challenges and achieve the desired results.

Environmental Responsibility: Adhere to environmental regulations and responsible practices for handling and disposing of chemicals used in the process.

Multi-color anodizing can produce stunning visual effects, but it requires meticulous attention to detail, careful process control, and a deep understanding of both the anodizing and coloring processes. By addressing challenges and following best practices, you can achieve consistent and vibrant multi-color finishes.

Conclusion

Learn about the multi-color anodizing process, what it is and what its benefits are in this article. If you want to know more about aluminum multi-color anodizing, please contact us today. CNCMF can provide a wide range of CNC machining manufacturing capabilities and surface treatment services to meet all your CNC machined part production needs at the best, competitive prices. Why not give CNCMF a try and contact us now to get a quote.

Frequently Asked Questions About Multi-Color Anodizing

Certainly, here are responses to common questions customers may have about multi-color anodizing:

1. Color Matching:

Can you precisely match specific colors in multi-color anodizing?

Achieving exact color matching can be challenging due to factors like material variation and process conditions. However, we make every effort to come as close as possible to your specified colors and recommend providing color samples or references for the best results.

2. Color Variation:

Why do I sometimes see slight color differences between parts or batches?

Color variation can arise from variations in alloy composition, surface preparation, and anodizing conditions. We implement stringent quality control measures to minimize variations, but minor tolerances may exist.

3. Cost and Pricing:

How does the cost of multi-color anodizing compare to standard anodizing?

Multi-color anodizing is typically more expensive than standard anodizing due to its complexity. Costs depend on factors such as design intricacy, quantity, and the number of colors. We provide detailed quotes based on project-specific requirements.

4. Lead Times:

What is the expected lead time for multi-color anodizing projects?

Lead times can vary based on project complexity and volume. We aim to provide accurate estimates for turnaround times, taking into account the scope of the project and our current production schedule.

5. Design Guidance:

Do you have any design recommendations for multi-color anodizing?

Response: We can offer design guidance to help optimize your project for multi-color anodizing. This includes suggestions for masking, color selection, and design considerations to achieve the desired visual effects.

6. Environmental Concerns:

Are there any environmental considerations with multi-color anodizing?

We adhere to environmental regulations and use eco-friendly processes whenever possible. We ensure proper handling and disposal of chemicals to minimize environmental impact.

Please feel free to reach out if you have any additional questions or specific project requirements. We’re here to assist you throughout the multi-color anodizing process.