Copper can be said to be a very common material for CNC machining, but many people don’t know what types of copper are. In our daily processing process, these materials can be processed: brass, bronze, red copper (also known as red copper), cupronickel, etc., in order to facilitate everyone to understand the difference between brass CNC mahining materials,CNCMF has prepared common copper knowledge for everyone.

What is brass?

Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a variety of alloys composed of more than two elements, it is called special brass.

Brass application scenarios

Because brass has strong wear resistance, brass is often used to make valves, water pipes, connecting pipes for internal and external air conditioners, radiators, epidemic buckles, etc.

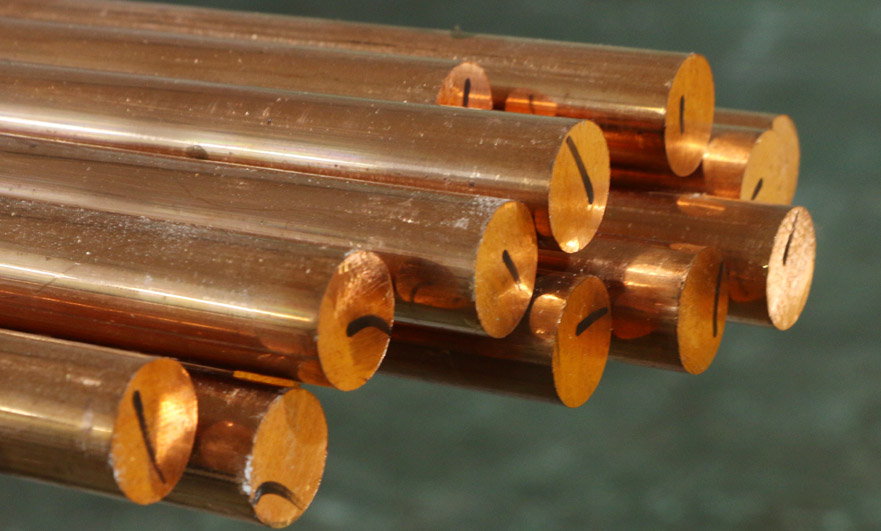

What is copper?

Red copper is a simple substance of copper. Because of its purple-red color, it is also called red copper. Red copper is industrial pure copper with a melting point of 1083°C, no allotropic phase change, and a relative density of 8.9, which is 5 times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Red copper is generally called red copper because of its rosy red and purple color after an oxide film is formed on its surface. Copper containing a certain amount of oxygen, so it is also called oxygen-containing copper.

Copper application scenarios

Red copper is a relatively pure copper. Generally it can be approximated as pure copper. Has good electrical conductivity and plasticity, but low strength and hardness. Therefore, general copper can be mainly used in electrical appliances, steam construction and chemical industries. Especially the terminal printed circuit board.

What is bronze?

Originally referred to as copper-tin alloy, later copper alloys other than brass and cupronickel were called bronze, and bronze was the name of the first main added element.

Bronze application scenarios

Tin bronze has good casting properties, anti-friction properties and good mechanical properties, and is suitable for manufacturing bearings, worm gears, gears, etc. Lead bronze is a bearing material widely used in modern engines and grinders. Aluminum bronze has high strength, good wear resistance and corrosion resistance, and is used for casting high-load gears, bushings and marine propellers. Plated bronze and phosphor bronze have high elastic limit and good electrical conductivity, and are suitable for manufacturing precision springs and electrical contact components. Copper plating is also used to make non-sparking tools used in coal mines and oil depots.

What is copper-nickel alloy?

A copper alloy with nickel as the main additive element. Copper-nickel binary alloy is called ordinary white mace; cupronickel alloy containing manganese, iron, zinc, aluminum and other elements is called compound cupronickel.

Copper-nickel alloy application scenarios

Industrial copper-nickel alloys are divided into two categories: structural copper-nickel alloys and electrical white copper-nickel alloys. The structural characteristics of cupronickel are good mechanical properties and corrosion resistance, and beautiful color. This copper-nickel alloy is widely used in the manufacture of precision machinery, chemical machinery and ship parts. Electrical white copper generally has good thermoelectric properties. Manganin, constantan and test copper are manganese cupronickel with different manganese content. They are used to manufacture precision electrical instruments, varistors, precision resistors, strain gauges, thermocouples, etc.

How to distinguish them?

1. Distinguish by color

Cupronickel, brass, red. Copper (also called “red copper”) and bronze (green-gray or gray-yellow) are distinguished by color.

2. Features

Cupronickel and brass are easy to distinguish; red. Copper is pure copper (impurities <1%) and bronze (other alloy components are about 5%). It’s a bit difficult to distinguish. When it is not oxidized, the red copper color is brighter than the bronze color, and the bronze color is slightly cyan or yellowish, and the color is darker; after oxidation, the red copper becomes black, and the bronze becomes cyan (harmful oxidation due to water) or chocolate color.

Summarize

The characteristics and application scenarios of copper are different, and we can distinguish them by the color of the material. When it is difficult to distinguish, we must make proper use of characteristics to distinguish. We have already talked about brass CNC machining materials, and I hope this article can help you. Thanks for watching.