Swiss CNC turning and traditional CNC turning are two different methods used to process metal or other raw material parts. Specifically, machining is the process of taking material from a workpiece and shaping it into a predetermined design.

The difference between CNC turning and Swiss CNC turning

Does traditional CNC machining solve my problem, or does it require Swiss CNC machining? What is the difference between the two?

Both have different advantages and applications, but their processing processes are very different. Which precision CNC machining process to choose depends on the specific job.

CNC turning

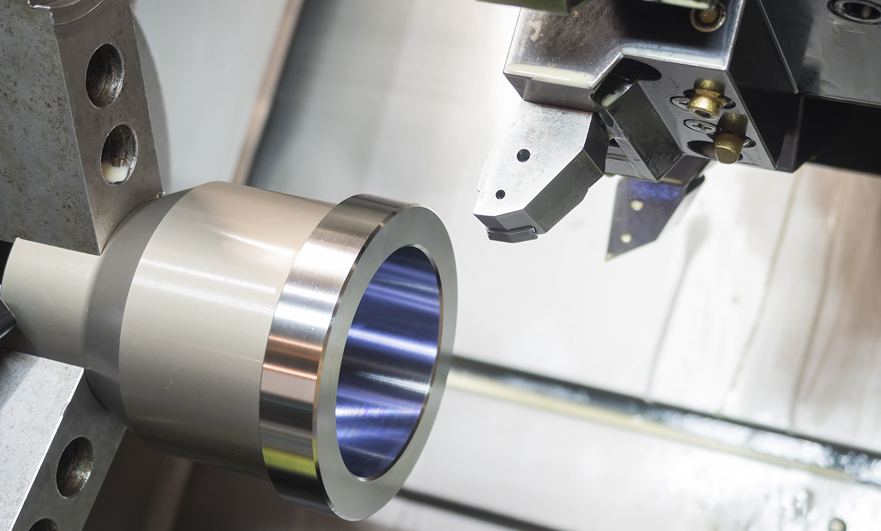

In CNC machining, the workpiece rotates at a fixed position at high speed, and the tool moves along the workpiece. The tool removes material from the workpiece to produce the desired shape. In order to provide higher accuracy and repeatability, this machine adopts closed-loop control mode. Processing parameters depend on the nature of the material, tool characteristics, cutting depth and finishing requirements.

Features of CNC turning include:

1. The main applications of CNC turning are forging, casting and bar stock.

2. The fixture can hold up to 40 parts.

3. It provides good surface quality for processed products.

4. It is used to produce parts with external grooves, threads and tapers.

5. It is mainly used to produce round and cylindrical parts.

6. It provides excellent repeatability and high precision in mass production.

Traditional turning extends the material from the chuck/chuck to the entire length of the part, and then the tool enters the rod. CNC turning is suitable for short and large diameter parts with very tight tolerances, as well as for processing large parts with complex material properties.

Swiss CNC turning

This process is mainly used to develop economical and sustainable mechanical parts for various industrial applications. In Swiss CNC turning, the workpiece moves along the Z axis to perform the cutting operation, while the tool remains stationary. Swiss precision CNC machining provides a cost-effective method for the production of parts for medical and defense products, such as dust-proof needles and shooting needles for military rifles. These elongated parts have a tolerance of 0.0005 inches in part diameter.

The Swiss-type lathe is composed of various CNC turning machines, feeding the workpiece through the guide bushing. This means that the turning tool can always cut the valve stem near the bushing, so no matter how long the workpiece is, it can be cut near the support point. This machine sends the work off the spindle and then through the tool. This makes the Swiss CNC system particularly suitable for slender turning parts. Advantages of the Swiss CNC lathe In the CNC turning process, the material is supported near the cutting tool. The guide sleeve is used to push the workpiece into the tool while preventing the workpiece from deflection.

The characteristics of Swiss CNC turning include the following:

1. Produce small machine parts with extremely high precision and accuracy.

2. Complex geometric shapes can be easily processed on Swiss CNC machines.

3. Allow multiple operations at the same time.

4. Both small batch production and mass production can be completed by Swiss CNC turning.

5. It can perform a variety of processing operations, including turning, milling, drilling, boring, etc.

6. Swiss CNC turning machining is mainly used for the development of medical and defense products.

7. It also assists in the manufacture of watch parts and shafts.

In traditional CNC turning, the workpiece is rotated in a fixed position and grasped tightly from one or both ends. On the other hand, in CNC Swiss CNC turning, the workpiece can rotate and move along the Z axis during the cutting process. Multiple operations can be performed on one machine at the same time.

What CNC turning machining should I use?

If you need something with minimal bending, or your project has a large number of small cylindrical parts with very tight tolerances, then Swiss CNC turning is the best method for you. On the other hand, traditional CNC turning has high repeatability, accuracy, versatility and processing speed. The processing methods and characteristics of the two are different, but Swiss CNC turning is a modern technology for turning operations. It is widely used by manufacturers to perform complex CNC machining operations, which is not done on other machines.

in conclusion

In the above article, we have come to the conclusion that according to different processing parts requirements, choose the appropriate CNC turning processing method. CNC turning will be the best choice for manufacturing cost-effective small and complex parts. The CNCMF processing and manufacturing plant will provide you with high-quality customized machining parts services and solutions through CNC turning and Swiss CNC turning.

If you are looking for a competitive price and high quality CNC turning manufacturing service tolerance, then CNCMF should be your first choice. Adhering to this: “You design, we make” service philosophy. We provide customers with one-stop service from drawing design to production and processing. If you have any technical support, you can contact our engineers or customers, 24 hours online. Get a quote now.