As a CNC machining product designer, you should understand the limitations of different processes:

The surface treatment of aluminum alloy is usually anodized, which is not suitable for electroplating.

The common surface treatment of zinc alloy die casting is electroplating, which is not suitable for anodizing.

Aluminum alloy die castings are also not suitable for anodizing effect is relatively poor, those with high appearance requirements should be used with caution.

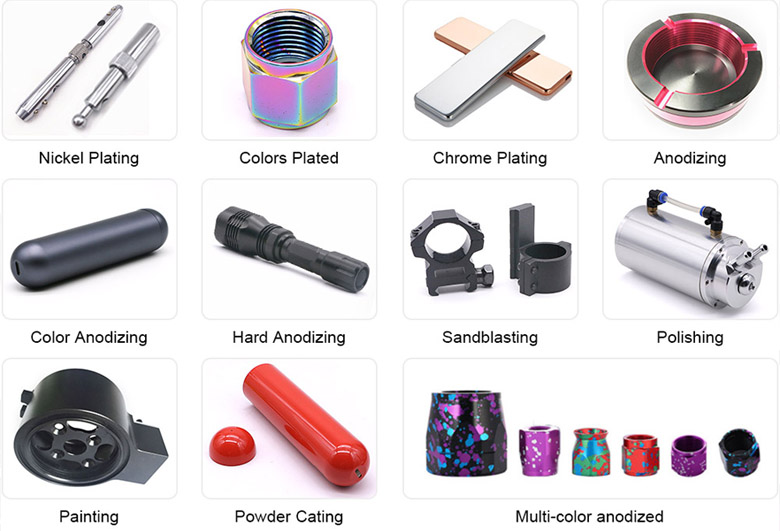

Usually the surface treatment of metal CNC machining parts will choose electroplating or anodizing, so what is the difference between these two processes?

Different treatment methods

What is electroplating?

Electroplating is to use the material to be electroplated as the cathode, and the same metal material as the plating metal as the anode (insoluble anodes are also used), and the electrolyte is a solution containing the plating metal ions; a certain current is input between the anode and the cathode. The coating material and the material to be electroplated are two different materials, such as nickel plating on beryllium copper, where beryllium copper is the base material and nickel is the coating.

What is anodizing?

Anodizing uses chemical or electrochemical treatment to produce a film layer containing the metal component on the metal surface. The material to be treated is used as the anode, and is protected by a material that forms a film layer on the surface by applying an external current in a specific electrolyte. For example, the oxidation of aluminum alloy forms a thin film of aluminum oxide on the surface of aluminum alloy. Aluminum oxide is chemically stable, will not be oxidized again, is not corroded by acid, and can be dyed into various colors.

The processing object is different

The objects to be electroplated are mainly metals, but they can also be non-metals. The most commonly used electroplating metals are nickel, chromium, tin, copper, silver and gold, zinc, etc., usually referred to as nickel plating, chrome plating, zinc plating, etc. for short.

Anodizing is a metal surface treatment method. Most metallic materials (such as stainless steel, zinc alloys, aluminum alloys, magnesium alloys, copper alloys, titanium alloys) can be anodized in a suitable electrolyte.

The processing principle is different

Electroplating uses the part material as the cathode, and anodizing uses the part material as the anode.

Electroplating is due to the charge effect, the metal anode ions move to the cathode where they get electrons and deposit on the part to be plated. At the same time, the metal dissolution of the anode continuously replenishes the metal ions in the electrolyte.

There are six elements in the electroplating solution: main salt, additional salt, complexing agent, buffering agent, anode activator and additive.

The principle of electroplating includes four aspects: electroplating solution, electroplating reaction, electrode and reaction principle, and metal electrodeposition process.

Anodizing uses the easy-to-oxidize property of aluminum alloy to control the formation of oxide layer by electrochemical method to prevent further oxidation of aluminum and increase the mechanical properties of the surface.

Generally, aluminum or aluminum alloy is used as the anode, and the lead plate is used as the cathode. The aluminum and lead plates are electrolyzed in an aqueous solution of sulfuric acid, oxalic acid, chromic acid, etc., so that an oxide film is formed on the surface of the aluminum and lead plates. Among these acids, sulfuric acid is most widely used in anodizing.

Aluminum alloy anodizing technology is currently the most widely used and most successful. Aluminum alloy anodizing can greatly improve the surface hardness, wear resistance and other indicators.

There are a large number of micropores in the thin layer of oxide film, which can absorb various lubricants, and is suitable for manufacturing engine cylinders or other wear-resistant parts; the film micropores have strong adsorption capacity and can be colored into various beautiful and bright colors. Non-ferrous metals or their alloys (such as aluminum, magnesium and their alloys, etc.) can be anodized. This method is widely used in mechanical parts, aircraft and auto parts, precision instruments and radio equipment, daily necessities and architectural decoration.

Why is aluminum alloy not suitable for electroplating?

The chemical property of aluminum is relatively active. If it is electroplated, in the acidic electrolyte, the aluminum ions on the cathode will generate aluminum salt and hydrogen gas while obtaining electron reduction. If it is an alkaline electrolyte, aluminum hydroxide and hydrogen are generated. Therefore, aluminum cannot be coated by electroplating. This is the same as electrolysis of salt water to get sodium hydroxide instead of sodium metal.

Why is aluminum alloy suitable for anodizing?

First of all, aluminum alloy has many advantages, such as light weight, corrosion resistance, good processing performance, high thermal conductivity, good electrical conductivity and so on. However, aluminum alloy itself has many disadvantages and weaknesses:

1. The hardness of aluminum is relatively low, and at the same time, the wear resistance is also relatively poor.

2. Aluminum shrinks greatly when it solidifies.

3. The expansion coefficient of aluminum is high.

4. The melting point of aluminum is relatively low, and the use temperature cannot exceed 200°C, so the use of high temperature is limited.

5. The modulus of elasticity of aluminum is only 1/3 of that of steel.

6. The potential of aluminum is very negative, so when aluminum is in contact with dissimilar metals, it is easy to cause serious galvanic corrosion as an anode.

The anodic oxidation of aluminum is to overcome the above-mentioned shortcomings of aluminum, mainly the defects of aluminum surface properties, so as to expand the application range and service life of aluminum. Fundamentally speaking, it is to improve the protection, decoration and functionality of aluminum alloy.

Protectiveness mainly refers to preventing the corrosion of aluminum and protecting the appearance of aluminum. Decoration is mainly based on aesthetics, improving its appearance quality, such as improving metallic luster and various colors. Functionality refers to increasing surface hardness, wear resistance, electrical insulation, etc., and using the porous type of anodized film, it can also endow the surface with electromagnetic and photoelectric functions.

Need to pay attention to the poor oxidation surface effect of die-casting aluminum alloy

Cast aluminum alloys and die-casting parts generally contain high silicon content, and the anodized film is dark in color, and it is impossible to obtain a colorless and transparent oxide film. With the increase of silicon content, the color of the anodized film changes from light gray to Dark gray to dark gray. Therefore cast aluminum alloys are not suitable for anodizing.

However, the effect of anodic oxidation treatment on zinc alloy die castings will be particularly poor, and the yield rate is very low, and anodic oxidation treatment is also a very cumbersome process. Zinc alloy die castings usually use electroplating surface treatment process.

The above is the difference between electroplating and anodizing, I hope it will be helpful to you. Contact us now.