Although precision CNC machining parts, workpiece materials and CNC machining processes are very different, all CNC machining manufacturers have a common goal, which is to CNC process a certain number of workpieces with the expected quality within a specified time and at an appropriate cost.

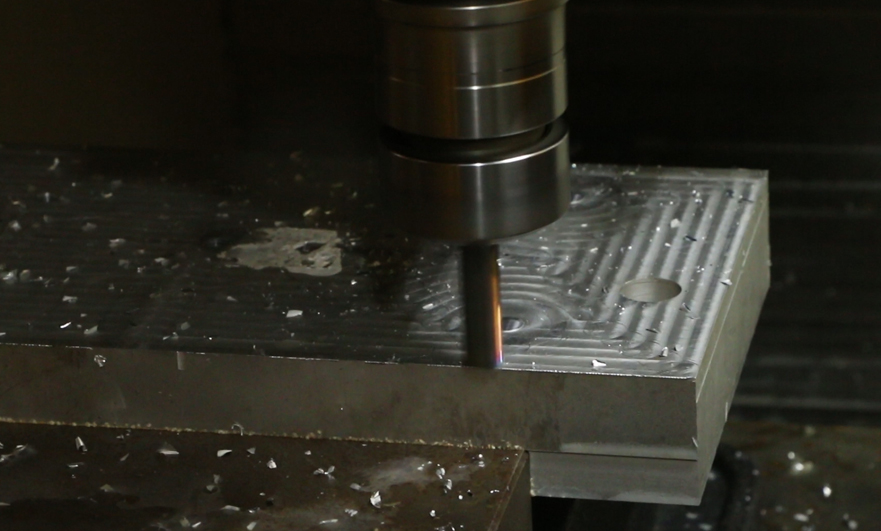

In the metal CNC machining process, the tool is the most direct factor that affects the cutting process. Cutting force, cutting heat, tool life and surface quality of precision CNC machined parts are closely related to tool geometric parameters. Ai et al. pointed out that tool geometry parameters have a great influence on tool durability. Denkner and Bierman believe that the service life and performance of a tool are determined by the geometry of the blade. Under the premise of fixed factors such as machine tools, tool materials, precision CNC machining parts materials, and cutting parameters, tool geometric parameters will affect the cutting performance of the tool, extend tool life, and greatly increase productivity.

In terms of tool geometry parameter optimization, Pan et al. The optimization of geometric parameters (end mill helix angle) and cutting parameters (axial and radial depth) of high-speed milling aerospace aluminum alloy cutters with minimum cutting force as a single objective function is studied. Research shows that when the cutting axial depth and radial depth are within the range of 5~7mm and 3~5mm, the helix angle of the face milling cutter can obtain the minimum cutting force within the range of 35°~40°. Through a strict analytical formula, Wan et al. studied the mechanism of the helix angle of the peripheral milling cutter on the peak cutting force. The conclusion is that according to the axial depth of the cutting, the number of grooves and the diameter of the milling cutter, the best helix angle corresponding to the minimum peak cutting force can be designed.

Mia et al. discussed the optimization of the minimum cutting force and the minimum lubrication flow (MQL) of the surface roughness in the end milling of hardened steel (HRC 40), and proposed a flow rate of 150 ml/h to ensure the minimum cutting force and precise numerical control. Surface roughness of machined parts. However, the complex relationship between cutting force and surface roughness is still unclear. In the future, precision CNC machining parts still need to attract researchers’ attention.

Although precision CNC machining parts, workpiece materials and CNC machining processes are very different, all CNC machining manufacturers have a common goal, which is to CNC process a certain number of workpieces with the expected quality within a specified time and at an appropriate cost.

In the metal CNC machining process, the tool is the most direct factor that affects the cutting process. Cutting force, cutting heat, tool life and surface quality of precision CNC machined parts are closely related to tool geometric parameters. Ai et al. pointed out that tool geometry parameters have a great influence on tool durability. Denkner and Bierman believe that the service life and performance of a tool are determined by the geometry of the blade. Under the premise of fixed factors such as machine tools, tool materials, precision CNC machining parts materials, and cutting parameters, tool geometric parameters will affect the cutting performance of the tool, extend tool life, and greatly increase productivity.

In terms of tool geometry parameter optimization, Pan et al. The optimization of geometric parameters (end mill helix angle) and cutting parameters (axial and radial depth) of high-speed milling aerospace aluminum alloy cutters with minimum cutting force as a single objective function is studied. Research shows that when the cutting axial depth and radial depth are within the range of 5~7mm and 3~5mm, the helix angle of the face milling cutter can obtain the minimum cutting force within the range of 35°~40°.

Through a strict analytical formula, Wan et al. studied the mechanism of the helix angle of the peripheral milling cutter on the peak cutting force. The conclusion is that according to the axial depth of the cutting, the number of grooves and the diameter of the milling cutter, the best helix angle corresponding to the minimum peak cutting force can be designed. Mia et al. discussed the optimization of the minimum cutting force and the minimum lubrication flow (MQL) of the surface roughness in the end milling of hardened steel (HRC 40), and proposed a flow rate of 150 ml/h to ensure the minimum cutting force and precise numerical control. Surface roughness of machined parts. However, the complex relationship between cutting force and surface roughness is still unclear. In the future, precision CNC machining parts still need to attract researchers’ attention.