What is Water Transfer Printing?

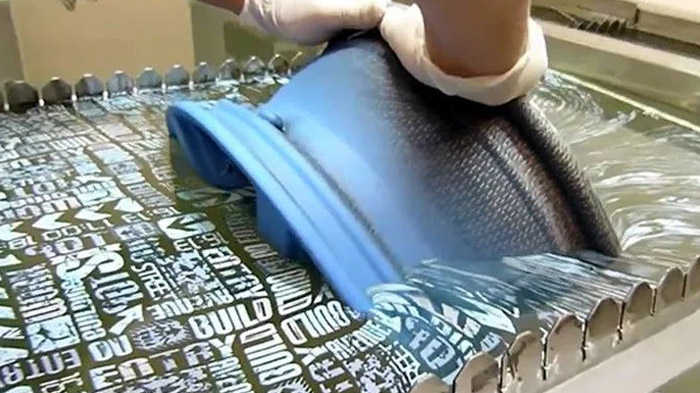

Water transfer printing, also known as hydrographic printing or hydro dipping, is a surface decoration process used to apply intricate and detailed patterns or designs onto three-dimensional objects. This technique involves transferring a printed design from a water-soluble film onto the surface of an object, typically made of materials like plastics, metals, ceramics, or composite materials. Here’s how the process works:

Film Preparation: A water-soluble film is printed with the desired pattern or design. This film is often made of PVA (polyvinyl alcohol) and is known as the “hydrographic film.” The film can feature various patterns, including woodgrain, camouflage, carbon fiber, marble, and custom graphics.

Water Tank: A tank or container is filled with water at a controlled temperature. The water’s temperature is crucial because it affects the film’s activation and adhesion to the object’s surface.

Activator Solution: An activator solution is sprayed onto the surface of the water in the tank. This activator contains chemicals that dissolve the printed design on the film, creating a liquid ink or paint-like layer on the water’s surface.

Film Immersion: The printed hydrographic film is carefully placed on the water’s surface, allowing the inked design to float. The film typically begins to dissolve upon contact with the activator solution, creating a sheet of floating ink.

Object Dipping: The object to be decorated is carefully dipped into the water, submerging it beneath the floating ink layer. The ink adheres to the object’s surface as it is submerged, wrapping around the contours and adhering to every detail.

Rinsing and Drying: After the object is removed from the water tank, any residual ink or film is rinsed off. The object is then dried, often in an oven or using other drying methods.

The result is a seamless and high-resolution pattern or design that conforms to the shape and contours of the object. Water transfer printing is commonly used for customizing various products, including automotive parts, sporting goods, firearms, electronics, and even home decor items. It allows for intricate and visually appealing surface decorations that are both durable and long-lasting.

Why Choose Aluminum Water Transfer Printing? Can Plastic be Water Transfer Printed?

Choosing aluminum water transfer printing (also known as hydrographic printing) can be advantageous for several reasons, and it’s also worth considering its applicability to plastic surfaces:

Advantages of Aluminum Water Transfer Printing:

Aesthetic Versatility: Aluminum can be water transfer printed with a wide range of patterns, including woodgrain, carbon fiber, camouflage, and custom graphics. This versatility allows for customized and visually appealing finishes on aluminum surfaces.

Durable Finish: Water transfer printing provides a durable and long-lasting finish on aluminum, enhancing its resistance to wear, scratches, and environmental factors. This is particularly beneficial for applications where aluminum components may be subjected to harsh conditions.

Enhanced Appearance: The process can give aluminum components an enhanced appearance that mimics the look of premium materials like wood, marble, or metallic finishes. This can be particularly appealing for applications where aesthetics are crucial.

Conformity to Complex Shapes: Water transfer printing is capable of conforming to the intricate shapes and contours of aluminum parts, ensuring that the pattern or design covers the entire surface uniformly.

Customization: Custom graphics and designs can be applied to aluminum using water transfer printing, allowing for branding, personalization, or unique aesthetics.

Versatility in Applications: Aluminum water transfer printing finds applications in various industries, including automotive, aviation, marine, sporting goods, and home decor, where both aesthetics and durability are important.

As for plastic surfaces, water transfer printing is indeed applicable to many types of plastic. The process can be used on various plastics, including ABS, polypropylene, PVC, and more. The suitability of water transfer printing for plastics depends on the specific type of plastic, its surface condition, and the intended application.

However, it’s important to note that the adhesion and durability of the water transfer printed finish on plastic may vary compared to other materials like metal. Some plastics may require additional surface preparation or treatments to ensure proper adhesion and longevity of the printed design. Therefore, while water transfer printing is versatile and can be used on both aluminum and plastic, the specific plastic material and its intended use should be considered when determining its suitability.

Water Transfer Printing Process

The water transfer printing process, also known as hydrographic printing or hydro dipping, involves several steps to apply a decorative pattern or design onto a three-dimensional object’s surface. Here’s an overview of the water transfer printing process:

Surface Preparation:

The object’s surface is cleaned thoroughly to remove any dirt, grease, or contaminants. Proper surface preparation is crucial to ensure good adhesion of the printed design.

Film Selection:

A water-soluble film, often made of PVA (polyvinyl alcohol), is chosen with the desired pattern or design. This film is known as the “hydrographic film” and serves as the carrier for the design.

Printing the Film:

The selected film is loaded into a specialized printer, which prints the chosen design onto the film using high-quality inks. This design can range from woodgrain and camouflage patterns to custom graphics.

Activator Application:

An activator solution is applied to the printed film. This solution contains chemicals that activate the ink and dissolve the PVA film, creating a liquid ink layer on the water’s surface.

Film Immersion:

The object to be decorated is carefully lowered or dipped into a tank filled with water. The printed hydrographic film is placed on the water’s surface, and the inked design starts to dissolve into a liquid form.

Transfer and Adhesion:

As the object is submerged, the ink adheres to its surface, wrapping around its contours and adhering uniformly. The design conforms to the shape of the object, even in complex or intricate areas.

Rinsing and Drying:

After the object is removed from the water tank, any residual ink or film is rinsed off. The decorated object is then dried thoroughly, typically in an oven or through other drying methods.

Clear Coat (Optional):

In some cases, a clear protective coating may be applied to the decorated surface to enhance durability and protect the design from wear, UV rays, and environmental factors.

The water transfer printing process results in a high-resolution and visually appealing finish that conforms to the shape and contours of the object. This technique is used for customizing a wide range of products, including automotive parts, sporting goods, electronics, firearms, and more. Its versatility, durability, and ability to achieve intricate designs make it a popular choice for both decorative and functional applications.

Water Transfer Printing Advantages and Disadvantages

Certainly, here are the advantages (pros) and disadvantages (cons) of water transfer printing:

Advantages (Pros) of Water Transfer Printing:

Aesthetic Versatility: Water transfer printing allows for a wide range of design options, including intricate patterns, woodgrain, marble, camouflage, and custom graphics. This versatility makes it suitable for various applications.

Durable Finish: The process results in a durable and long-lasting finish that can withstand wear, scratches, and environmental factors. It enhances the longevity of the decorated object.

Conformity to Complex Shapes: Water transfer printing can conform to the intricate shapes and contours of three-dimensional objects, ensuring uniform coverage and a seamless finish.

Customization: Custom graphics and designs can be applied, providing opportunities for personalization and branding on a variety of products.

Enhanced Appearance: It can significantly enhance the appearance of objects, replicating the look of premium materials like wood, marble, or metallic finishes.

Versatility in Applications: Water transfer printing finds applications in various industries, including automotive, aviation, marine, sporting goods, electronics, and home decor, where aesthetics and durability are essential.

Disadvantages (Cons) of Water Transfer Printing:

Limited Material Compatibility: Water transfer printing is more compatible with certain materials, such as plastics, metals, ceramics, and composites, but may not be suitable for all materials. Some materials may require additional surface treatments or may not be suitable for the process.

Skill and Equipment Requirement: Proper execution of water transfer printing requires skill and specialized equipment, including tanks, activators, and printers. This can pose challenges for individuals or businesses new to the technique.

Waste Generation: The process generates waste in the form of unused PVA film and rinse water. Proper disposal or recycling of these materials is essential to minimize environmental impact.

Complex Process: Water transfer printing involves multiple steps, including film preparation, printing, activation, dipping, rinsing, and drying. Each step must be executed carefully to achieve the desired result.

Ink Adhesion: The quality of ink adhesion may vary depending on the material being printed, the surface preparation, and the specific ink used. Proper surface preparation is crucial for good adhesion.

Not Suitable for High-Heat Environments: Water transfer printing may not be suitable for objects exposed to extreme heat or high-temperature environments, as the ink and film may not withstand such conditions.

Cost: The initial investment in equipment and materials for water transfer printing can be relatively high, which may deter smaller businesses or individuals from adopting the technique.

In summary, water transfer printing offers numerous advantages in terms of aesthetics, durability, and customization but also comes with certain limitations and requirements. Proper training, equipment, and material selection are crucial for achieving successful outcomes with this decorative process.

Which Metals are Suitable for Water Transfer Printing Surface Treatment?

Water transfer printing can be applied to various metals material, but its suitability depends on factors such as the type of metal, surface preparation, and the intended application. Here are some metals commonly used in water transfer printing:

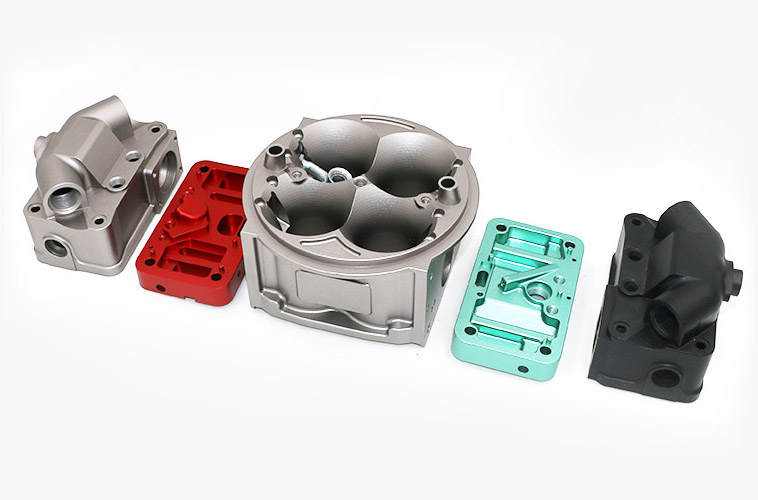

Aluminum: Aluminum is a popular choice for water transfer printing due to its versatility and durability. It can be used in automotive parts, sporting goods, and decorative applications.

Steel: Steel, including stainless steel, can be suitable for water transfer printing. Stainless steel is often used for firearms, automotive trim, and industrial equipment.

Copper and Brass: These metals can be decorated using water transfer printing. They are often chosen for decorative and artistic applications, such as sculptures and jewelry.

Zinc: Zinc can also be used in water transfer printing, primarily for decorative purposes. It’s commonly used in hardware and accessories.

Titanium: Titanium can be water transfer printed, especially in applications where a lightweight, durable, and corrosion-resistant material is required, such as in the aerospace industry.

Magnesium: While less common, magnesium can be decorated through water transfer printing for specific applications like automotive components and lightweight structural parts.

Chrome-Plated Surfaces: Water transfer printing can also be applied to chrome-plated surfaces to achieve custom finishes and patterns.

It’s important to note that the success of water transfer printing on metal surfaces depends on several factors, including surface preparation, the quality of the ink, and the specific design or pattern being applied. Proper cleaning, degreasing, and surface treatment are essential to ensure good adhesion and a durable finish.

Additionally, some metals may require specific pre-treatment processes or primers to improve ink adhesion. When considering water transfer printing on metal, it’s advisable to consult with experienced professionals or specialists who can provide guidance on material compatibility and the best practices for achieving the desired results.

What Surface Effect does Water Transfer Printed Aluminum Parts Exhibit?

Water transfer printing on aluminum parts can produce a wide range of surface effects and finishes, depending on the chosen hydrographic film or pattern. Here are some common surface effects and finishes that can be achieved through water transfer printing on aluminum:

Woodgrain: Water transfer printing can replicate the appearance of various wood species, creating a realistic woodgrain finish on aluminum parts. This effect is popular for interior automotive trim, furniture, and decorative elements.

Carbon Fiber: Aluminum components can be given a carbon fiber pattern, mimicking the look of lightweight and high-performance carbon fiber materials. This finish is often used in automotive and sporting goods applications.

Marble and Stone: Water transfer printing can replicate the elegant appearance of marble or stone surfaces. It’s commonly used in architectural and interior design elements to achieve a luxurious and natural look.

Camouflage: Camouflage patterns are popular for outdoor and sporting equipment, and water transfer printing can create intricate and detailed camouflage designs on aluminum parts.

Custom Graphics: Water transfer printing allows for the application of custom graphics, logos, and unique designs. This versatility is ideal for branding and personalization on aluminum products.

Metallic Finishes: Aluminum can be given metallic finishes, such as chrome, brushed aluminum, or metallic colors. These finishes provide a sleek and modern appearance.

Abstract Patterns: Water transfer printing can also be used to apply abstract patterns and artistic designs, offering a high level of creativity and customization.

The choice of hydrographic film or pattern will determine the final surface effect. Additionally, a clear protective coating may be applied after water transfer printing to enhance the durability and protect the surface finish from wear, UV exposure, and environmental factors.

Water transfer printing on aluminum not only enhances the aesthetics of the parts but also provides durability and resistance to scratches and abrasion. This makes it suitable for a wide range of applications, including automotive trim, motorcycle components, consumer electronics, and more, where both visual appeal and performance are essential.

Water Transfer Printing vs. Other Surface Treatments: Differences, Surface Effects and Cost Comparison

Water transfer printing, often referred to as hydrographic printing or hydro dipping, is one of several surface finishing methods available for enhancing the appearance and durability of objects. Let’s compare it to other common surface treatment methods in terms of differences, surface effects, and cost considerations:

Water Transfer Printing (Hydrographic Printing):

Difference: Water transfer printing involves immersing an object into a water tank with a printed hydrographic film on its surface, allowing the design to adhere to the object’s contours. It is known for its ability to create intricate patterns and designs on three-dimensional objects.

Surface Effects: Water transfer printing can achieve a wide range of surface effects, including woodgrain, carbon fiber, marble, camouflage, and custom graphics. It is highly versatile in terms of aesthetics.

Cost: The cost of water transfer printing can vary depending on factors such as the size of the object, complexity of the design, and the quality of materials used. It may require specialized equipment and training, which can contribute to the overall cost.

Powder Coating:

Difference: Powder coating involves applying a dry powder onto the surface of an object and then curing it to create a protective and decorative finish. It is commonly used for metals and offers durability and corrosion resistance.

Surface Effects: Powder coating can create a smooth and even finish, and it comes in a variety of colors and finishes. It is known for its durability and resistance to chipping and fading.

Cost: Powder coating is generally cost-effective, especially for large batches of objects. The cost depends on factors like size, material, and the complexity of the coating process.

Painting:

Difference: Painting involves applying liquid paint to an object’s surface. It is a versatile surface treatment method that can be used on various materials, including metals, plastics, and wood.

Surface Effects: Painting offers a wide range of surface effects, including gloss, matte, metallic, and custom colors. It allows for precise customization and artistic expression.

Cost: The cost of painting varies depending on factors like the type of paint used, the size of the object, and the complexity of the design. It can be relatively cost-effective for small-scale projects.

Anodizing (For Aluminum):

Difference: Anodizing is a process specific to aluminum, where an oxide layer is formed on the surface through an electrochemical process. It enhances corrosion resistance and can also be used for decorative purposes.

Surface Effects: Anodizing provides a durable, non-conductive surface that can be dyed to achieve different colors and finishes. Common finishes include clear, black, and various shades of bronze.

Cost: Anodizing costs can vary based on factors such as size, type of anodizing (e.g., Type II or Type III), and the desired finish. It is generally competitive for aluminum applications.

Each of these surface treatment methods has its advantages and is suitable for different applications. The choice depends on factors such as the material, aesthetic preferences, durability requirements, and budget constraints. Consulting with experts in each field can help determine the most suitable method for a specific project.

Water Transfer Printing Surface Treatment Application

Water transfer printing, also known as hydrographic printing or hydro dipping, finds a wide range of applications across various industries due to its ability to enhance the appearance and durability of objects. Here are some common applications of water transfer printing:

Automotive Industry:

Water transfer printing is frequently used in the automotive industry to customize interior and exterior components. This includes dashboard trim, door panels, steering wheels, alloy wheels, and even entire vehicle bodies.

Firearms and Sporting Goods:

Firearm enthusiasts often use water transfer printing to personalize their guns with camouflage patterns, custom graphics, or tactical designs. Sporting goods like helmets, firearms stocks, and fishing equipment also benefit from this technique.

Aerospace:

In the aerospace sector, water transfer printing can be applied to aircraft interiors and components, offering both aesthetic improvements and protective coatings.

Marine Industry:

Boat manufacturers and owners use water transfer printing to decorate and protect marine components like hulls, consoles, and other interior elements.

Consumer Electronics:

Personal electronic devices, gaming consoles, and accessories can be customized using water transfer printing, allowing for unique designs and finishes.

Home Decor:

Water transfer printing is employed in the creation of decorative home items such as lampshades, vases, furniture, and picture frames.

Architectural Elements:

Architects and designers utilize water transfer printing to enhance architectural elements, such as ornate moldings, columns, and decorative panels.

Sports Equipment:

Sports equipment like helmets, golf clubs, and bicycle frames can feature custom designs and patterns through water transfer printing.

Fashion Accessories:

Water transfer printing is used on fashion accessories such as phone cases, sunglasses frames, and watch bands to provide a personalized touch.

Industrial Equipment:

In industrial settings, water transfer printing can be applied to machinery and equipment components for both aesthetic and protective purposes.

Personalization and Branding:

Many businesses use water transfer printing to brand their products with unique patterns, logos, and colors.

Art and Crafts:

Artists and craft enthusiasts employ water transfer printing for creating unique art pieces, sculptures, and home craft projects.

These are just a few examples of the diverse applications of water transfer printing. Its ability to combine aesthetics with durability and customization makes it a valuable technique across numerous industries and creative endeavors.

Problems and Precautions for Water Transfer Printing Aluminum Parts

When using water transfer printing on aluminum parts, there are several potential issues and important considerations to keep in mind to ensure a successful and high-quality result. Here are some common problems and precautions:

1. Surface Preparation:

Issue: Inadequate surface preparation can lead to poor adhesion of the printed design and result in defects.

Precaution: Thoroughly clean and degrease the aluminum surface before the water transfer printing process. Proper surface preparation is crucial for good ink adhesion.

2. Contaminants:

Issue: Any contaminants on the aluminum surface, such as oils, dust, or residues, can interfere with the adhesion of the design.

Precaution: Ensure that the aluminum surface is free from contaminants by using appropriate cleaning solutions and methods.

3. Proper Dipping Technique:

Issue: Incorrect dipping technique can cause design distortion or incomplete transfer.

Precaution: Train operators in the correct dipping method to ensure even and uniform transfer of the design onto the aluminum part.

4. Film Quality:

Issue: Low-quality hydrographic films may not provide the desired level of detail or adhesion.

Precaution: Use high-quality hydrographic films that are suitable for the specific design and intended application.

5. Bubbles and Wrinkles:

Issue: Bubbles or wrinkles in the hydrographic film can result in defects in the final design.

Precaution: Ensure that the hydrographic film is applied smoothly onto the water surface to prevent bubbles or wrinkles from forming.

6. Ink Adhesion:

Issue: Poor ink adhesion can lead to the design peeling or chipping over time.

Precaution: Use high-quality ink and activator solutions that are compatible with the aluminum surface. Proper ink adhesion is essential for long-lasting results.

7. Drying and Curing:

Issue: Inadequate drying and curing processes can affect the durability of the printed design.

Precaution: Follow recommended drying and curing times and temperatures to ensure that the design is fully cured and adhered to the aluminum surface.

8. Clear Coating (Optional):

Issue: Without a clear protective coat, the design may be vulnerable to wear and fading.

Precaution: Consider applying a clear protective coating over the printed design to enhance durability and protect against environmental factors.

9. Quality Control:

Issue: Failing to inspect the finished product for defects can result in subpar results.

Precaution: Implement a quality control process to inspect each water transfer printed aluminum part for defects and ensure consistency in the final finish.

By addressing these issues and following the recommended precautions, you can enhance the quality and longevity of water transfer printing on aluminum parts, achieving the desired aesthetic and functional results.

Conclusion

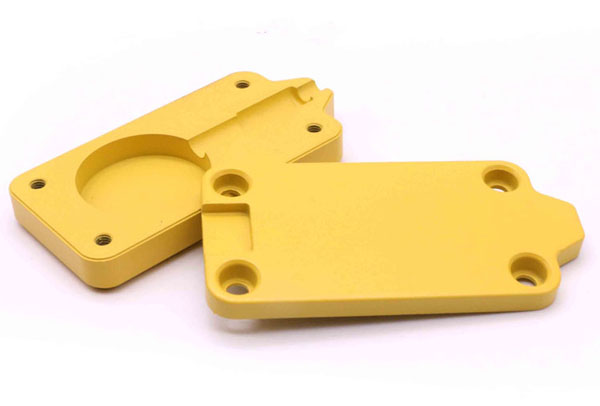

Do you know how to choose the right finish for your project? CNCMF has 15 years of experience in surface treatment experts to choose the appropriate surface treatment for you to improve the surface texture and performance of CNC parts.

Learn about the water transfer printing surface treatment process, advantages and applications according to this article. If you want to know more about water transfer printing surface treatment, please contact us immediately. CNCMF can provide a wide range of CNC machining and manufacturing capabilities and surface treatment services for steel, aluminum, titanium, copper and other materials. Our team of professional engineers can choose the appropriate surface treatment for you to meet all your CNC machined parts production needs and obtain the best results. Best, competitive price. Why not give CNCMF a try and contact us now to get a quote.

Water Transfer Printing FAQs

Certainly, here are some common questions and answers related to water transfer printing:

1. What is water transfer printing?

Water transfer printing, also known as hydrographic printing or hydro dipping, is a surface decoration technique that involves transferring a printed design from a water-soluble film onto the surface of three-dimensional objects. It is used to create custom and visually appealing finishes on various materials.

2. What materials can be decorated using water transfer printing?

Water transfer printing can be applied to a wide range of materials, including plastics, metals, ceramics, composites, and more. Common applications include automotive parts, sporting goods, electronics, and home decor items.

3. What types of designs can be achieved with water transfer printing?

Water transfer printing can create diverse surface effects, including woodgrain, carbon fiber, marble, camouflage, and custom graphics. The design possibilities are extensive, allowing for unique and personalized finishes.

4. Is water transfer printing durable?

Yes, water transfer printing results in a durable finish that is resistant to wear, scratches, and environmental factors when properly applied and cured. The durability can be enhanced further by applying a clear protective coating.

5. How is the water transfer printing process carried out?

The process involves several steps, including surface preparation, film selection and printing, activator application, film immersion, transfer and adhesion, rinsing, and drying. It is essential to follow each step carefully for successful results.

6. Can water transfer printing be applied to complex or intricate objects?

Yes, water transfer printing can conform to the intricate shapes and contours of three-dimensional objects, making it suitable for decorating even complex or highly detailed parts.

7. Are there any limitations to water transfer printing?

While versatile, water transfer printing may have limitations on certain materials and may not be suitable for extreme high-heat environments. Additionally, achieving high-quality results requires proper training and equipment.

8. How can I maintain the appearance of water transfer printed items?

To maintain the appearance and longevity of water transfer printed items, avoid abrasive cleaning methods and exposure to harsh chemicals. Gentle cleaning with mild detergents and periodic waxing or clear coat application can help protect the finish.

9. Can water transfer printing be used for branding or customization?

Yes, water transfer printing offers the opportunity to brand products with custom logos, graphics, and patterns, making it a valuable tool for businesses and individuals looking to personalize their items.

10. Is water transfer printing environmentally friendly?

Water transfer printing can be environmentally friendly when proper disposal and recycling practices are followed for unused film and rinse water. Additionally, some ink and film formulations are designed to be more eco-friendly.

Water transfer printing is a versatile and creative surface decoration technique that can transform ordinary objects into customized and visually stunning pieces. By understanding the process and its applications, individuals and businesses can make the most of this unique method.