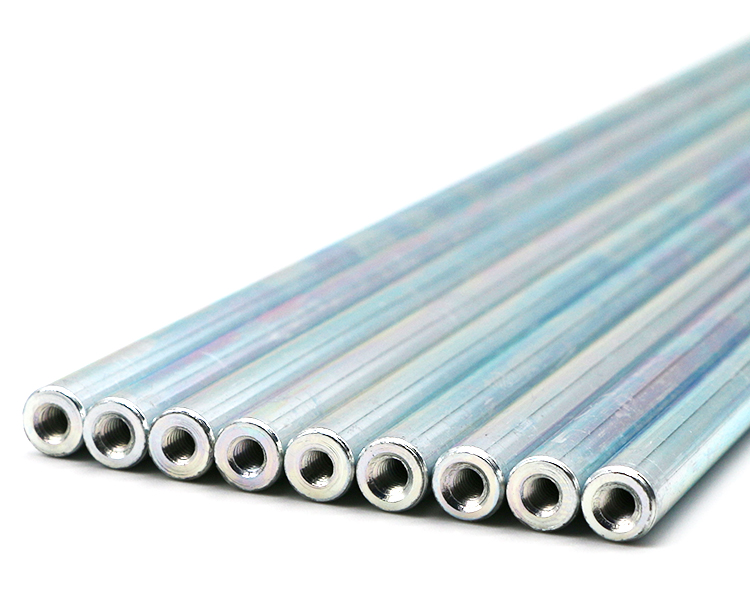

What is Blue Zinc Plating?

Blue zinc plating, often referred to as blue zinc passivation, is a type of electroplating process used to apply a layer of zinc onto the surface of steel or iron components. The “blue” in blue zinc plating refers to the color of the passivation coating that is applied on top of the zinc layer.

Why Choose Stainless Steel with Blue Zinc Plating?

Choosing stainless steel with blue zinc plating offers several advantages, making it a preferred option for various applications. Here are some reasons why stainless steel with blue zinc plating is a popular choice:

1. Corrosion Resistance: Stainless steel is inherently corrosion-resistant due to its composition, which includes chromium. When combined with blue zinc plating, it forms an additional layer of protection, making it highly resistant to rust and corrosion. This combination is ideal for components exposed to harsh environmental conditions or moisture.

2. Aesthetic Appeal: Blue zinc plating adds an attractive and distinctive blue tint to the stainless steel surface. This aesthetic enhancement is particularly valuable in applications where appearance matters, such as architectural elements, decorative hardware, and consumer goods.

3. Durability: Stainless steel is known for its durability and longevity. When combined with blue zinc plating, it further extends the lifespan of the components. This makes it suitable for parts that require a robust and long-lasting finish.

4. Reduced Maintenance: The corrosion-resistant properties of stainless steel with blue zinc plating reduce the need for frequent maintenance and replacement of components. This can lead to cost savings in the long run, especially in outdoor or corrosive environments.

5. Versatility: Stainless steel with blue zinc plating can be used in a wide range of applications across various industries, including construction, automotive, marine, and consumer goods. Its versatility makes it suitable for both structural and decorative purposes.

6. Compatibility: The combination of stainless steel and blue zinc plating is compatible with various manufacturing processes, such as machining, welding, and forming. This compatibility allows for flexibility in design and fabrication.

7. Environmental Considerations: Blue zinc plating typically involves water-based coatings with low VOC (volatile organic compound) emissions, making it an environmentally friendly choice compared to some other plating methods. Stainless steel is also recyclable and has a lower environmental impact.

In summary, choosing stainless steel with blue zinc plating provides a balance of corrosion resistance, durability, aesthetics, and versatility. It is a reliable option for components and parts where both functionality and appearance are essential, and where protection against rust and corrosion is paramount.

Which Metals are Suitable for Blue Zinc Plating Surface Treatment?

Blue zinc plating is typically applied to steel or iron components, as these metals material readily accept the zinc coating and passivation process. It provides excellent corrosion resistance and can enhance the appearance of these metals. Here are the common metals that are suitable for blue zinc plating:

Steel: Blue zinc plating is frequently used on various types of steel, including carbon steel and alloy steel. It helps protect steel parts from corrosion and enhances their durability.

Iron: Iron components can also be blue zinc plated to achieve corrosion resistance and a visually appealing finish.

Zinc-Coated Steel (Galvanized Steel): In some cases, galvanized steel components are further coated with blue zinc plating to enhance their corrosion protection and appearance.

While blue zinc plating is primarily applied to steel and iron, it is not typically used on other metals such as aluminum, copper, or brass. Each of these metals has different surface treatment requirements due to their unique properties and characteristics. Therefore, it’s essential to choose the appropriate plating or coating method based on the specific metal being used and the intended application.

Blue Zinc Plating Process Flow

The blue zinc plating process, also known as blue zinc passivation, involves several steps to apply a layer of zinc onto steel or iron components and then passivate the zinc coating to achieve the desired corrosion resistance and blue tint. Here is a general overview of the blue zinc plating process:

1. Cleaning and Preparation:

The first step involves thoroughly cleaning the steel or iron components to remove any dirt, grease, or contaminants from the surface. This cleaning is typically done through a series of chemical baths, ultrasonic cleaning, or abrasive methods.

2. Surface Activation:

In some cases, the metal surface is activated through processes like acid pickling or alkaline cleaning. This prepares the surface to receive the zinc coating effectively.

3. Zinc Electroplating:

The cleaned and prepared components are immersed in a bath of zinc plating solution. An electric current is applied to the bath, causing the zinc ions to be attracted to the metal surface. This results in the deposition of a layer of zinc onto the steel or iron parts. The thickness of the zinc layer can be controlled by adjusting the plating time.

4. Rinsing:

After the zinc plating process, the components are rinsed thoroughly to remove excess plating solution and any residual chemicals.

5. Passivation:

Passivation is a critical step in the blue zinc plating process. A passivation solution, which contains chromates or other chemicals, is applied to the zinc-coated surface. This solution forms a thin, protective layer on top of the zinc coating. It is this passivation layer that gives the plated components their distinctive blue tint.

6. Drying:

The passivated components are dried to remove any moisture from the surface. This ensures that the passivation layer is properly cured and adheres to the zinc coating.

7. Inspection and Quality Control:

The plated components undergo a thorough inspection to check for defects, uniformity, and adhesion of the zinc and passivation layers. Any imperfections are addressed before the parts are considered finished.

8. Packaging and Storage:

Finally, the blue zinc-plated components are packaged for shipping or storage. Proper packaging helps protect the finish during transport and ensures that the parts remain in good condition until they are used.

It’s important to note that the specific details of the blue zinc plating process may vary depending on factors such as the type of plating bath used, the composition of the passivation solution, and the quality control standards of the plating facility. Properly executed blue zinc plating provides both corrosion resistance and an attractive blue finish to steel and iron components.

Advantages and Disadvantages of Blue Zinc Plating

Blue zinc plating, also known as blue zinc passivation, offers several advantages and a few potential drawbacks. Here are the key benefits and drawbacks of this surface treatment:

Advantages of Blue Zinc Plating:

Corrosion Resistance: Blue zinc plating provides excellent corrosion resistance, making it an ideal choice for components exposed to harsh environments, moisture, and corrosive substances. It acts as a barrier that protects the underlying metal.

Aesthetic Appeal: The blue passivation layer imparts an attractive and distinctive appearance to the coated components. This is especially valuable for decorative applications where visual appeal is important.

Enhanced Durability: Blue zinc plating enhances the durability of steel and iron components, extending their lifespan and reducing maintenance requirements. This makes it suitable for parts subjected to wear and tear.

Reduced White Rust: The passivation layer helps reduce the formation of white rust, a type of corrosion that can occur on zinc-coated parts exposed to moisture. This further enhances the coating’s protective properties.

Cost-Effective: Blue zinc plating is a cost-effective way to provide both corrosion resistance and aesthetics to steel and iron components. It offers a balance between performance and affordability.

Disadvantages of Blue Zinc Plating:

Environmental Concerns: Traditional blue zinc passivation solutions may contain hexavalent chromium, a substance known for its environmental and health risks. More eco-friendly alternatives are being developed, but it’s important to consider the environmental impact.

Limited to Steel and Iron: Blue zinc plating is primarily suitable for steel and iron components. It is not typically used for other metals, limiting its versatility compared to some other coating methods.

Thickness Variability: Achieving consistent coating thickness can be challenging in certain applications. Variations in thickness may occur, which can affect the appearance and performance of the coating.

Complexity of Process: Blue zinc plating involves multiple steps, including cleaning, electroplating, passivation, and quality control. Managing and maintaining these processes can be complex and require expertise.

Health and Safety: Handling of chemicals and solutions in the plating process may require safety precautions and proper disposal methods to ensure the well-being of workers and environmental compliance.

In summary, blue zinc plating is a widely used surface treatment that offers significant benefits, including corrosion resistance, aesthetics, and durability. However, it is essential to consider its environmental impact and limitations, as well as ensure proper process control for consistent results. Advances in passivation solutions aim to address some of the environmental concerns associated with traditional blue zinc plating methods.

What Colors Can Be Galvanized?

Zinc plating, also known as galvanization, is primarily a corrosion-resistant coating rather than a coloring method. It provides a silver-gray or metallic appearance to the coated surface, similar to the natural color of zinc. However, it is possible to apply additional coatings or treatments to achieve different colors over zinc-plated surfaces. Here are some common methods to add color to zinc-plated components:

Painting: Zinc-plated parts can be painted with various colors using standard painting techniques. Paint adheres well to zinc coatings, providing a wide range of color options. This approach allows for customization to match specific design or branding requirements.

Powder Coating: Powder coating is another effective way to add color to zinc-plated surfaces. Powder coatings come in a variety of colors and can be applied electrostatically and then cured to create a durable and colorful finish.

Chemical Coloring: Chemical coloring processes involve immersing zinc-plated components in chemical solutions that react with the surface to produce colors. These processes are typically used for decorative applications. Examples include:

Black Passivation: Creates a black finish on zinc-plated parts by forming a layer of black zinc oxide on the surface.

Yellow Passivation: Produces a yellow or gold-colored finish on zinc-plated surfaces, often used for decorative fasteners.

Anodizing (For Aluminum): While not applicable to zinc-plated steel or iron, anodizing can be used to add color to aluminum surfaces. Anodized aluminum can achieve various colors, including black, red, blue, and more, by using different dyeing processes.

Electroplating: For specific applications, electroplating with different metals like copper, nickel, or chrome can be used to achieve colored finishes. These processes often involve multiple plating steps to build up layers and create the desired color.

Topcoats: Applying a clear or colored topcoat or lacquer over zinc-plated surfaces is another way to add color and protection. These topcoats can be customized to achieve various shades.

It’s important to note that the choice of coloration method depends on the material being coated (e.g., steel, aluminum) and the specific requirements of the application. Additionally, the quality of the finish and the longevity of the color may vary depending on the chosen method and the environmental conditions to which the coated parts will be exposed. Proper surface preparation and the use of suitable materials and processes are essential to achieve the desired color and durability over zinc-plated surfaces.

Galvanizing Classification: White Zinc Plating, Blue Zinc Plating, Colored Zinc Plating, Black Zinc Plating

Zinc plating, often referred to as galvanization, is a process of applying a protective zinc coating to steel or iron surfaces. While there are variations in the appearance and properties of zinc-plated surfaces, they are typically categorized into different types based on the specific treatment or passivation applied. Here are the common types of zinc plating:

Clear Zinc Plating (White Zinc):

Clear zinc plating provides a bright, silver-gray finish to the coated surface, resembling the natural color of zinc. It is used primarily for its corrosion-resistant properties and is suitable for a wide range of applications.

Blue Zinc Plating (Blue Zinc Passivation):

Blue zinc plating involves the same zinc coating as clear zinc plating, but it includes a passivation step that adds a blue-tinted protective layer on top of the zinc. This passivation enhances both corrosion resistance and aesthetics.

Colorful Zinc Plating (Rainbow Zinc or Color Passivation):

Colorful zinc plating is achieved by applying specialized passivation treatments over the zinc coating. This process can result in a range of colors, including gold, green, red, and blue. These colorful finishes are often used for decorative or aesthetic purposes.

Black Zinc Plating (Black Zinc Passivation):

Black zinc plating involves a passivation treatment that creates a black finish on the zinc-plated surface. This is used for applications where a sleek, black appearance is desired, such as in the automotive industry.

Differences from Galvanized Coating (Hot-Dip Galvanization):

Galvanized coating, or hot-dip galvanization, is a different process from zinc plating. It involves immersing steel or iron components into a bath of molten zinc, resulting in a thicker and more robust zinc layer. Galvanized coatings typically have a matte gray or dull appearance and are commonly used for outdoor applications due to their exceptional corrosion resistance.

Key differences between these types of zinc coatings include the method of application, the thickness of the zinc layer, and the specific properties of the coating. While zinc plating provides a thinner but versatile coating suitable for a variety of applications, hot-dip galvanization offers thicker and more durable protection, particularly for structural steel in harsh environments.

Each type of zinc coating has its advantages and applications based on factors such as cost, appearance, corrosion resistance, and the intended use of the coated parts. The choice of which type to use depends on the specific requirements of the project or application.

The Difference Between Chrome Plating, Nickel Plating and Zinc Plating

Chromium plating, nickel plating, and zinc plating are all surface coating processes used to protect and enhance the properties of metal components. However, they differ in several key ways:

1. Material Deposited:

Chromium Plating (Chrome Plating): Chromium plating involves depositing a layer of chromium onto the surface of a metal component. This process is primarily used for its aesthetic qualities and corrosion resistance. It provides a bright and reflective finish.

Nickel Plating: Nickel plating involves depositing a layer of nickel onto the surface of a metal component. Nickel plating offers good corrosion resistance and can be used for decorative purposes. It can provide a shiny, silvery finish.

Zinc Plating (Galvanization): Zinc plating, or galvanization, involves depositing a layer of zinc onto the surface of a metal component. Zinc plating is primarily used for corrosion protection and can have various appearances, including clear (silver-gray), blue, colorful, or black, depending on the type of zinc plating and passivation applied.

2. Purpose:

Chromium Plating: Chromium plating is commonly used for decorative purposes due to its bright and reflective finish. It is often applied to automotive trim, faucets, and other items where aesthetics are important.

Nickel Plating: Nickel plating offers a combination of corrosion resistance and aesthetic appeal. It is used for decorative items, as well as in industries like electronics and aerospace for its functional properties.

Zinc Plating: Zinc plating is primarily used for corrosion protection. It can be applied to a wide range of metal components, including fasteners, automotive parts, and structural steel, to prevent rust and corrosion.

3. Appearance:

Chromium Plating: Chromium plating provides a highly reflective, mirror-like finish. It is known for its “chrome” appearance, which is shiny and lustrous.

Nickel Plating: Nickel plating can vary in appearance depending on the desired finish. It can range from a bright, silvery finish to a more matte or brushed appearance.

Zinc Plating: Zinc plating can have various appearances, including a clear (silver-gray) finish for functional applications, or colorful finishes achieved through passivation treatments for decorative purposes.

4. Thickness:

Chromium Plating: Chromium plating is usually relatively thin, often only a few microns thick.

Nickel Plating: Nickel plating can vary in thickness, depending on the specific application and requirements.

Zinc Plating: Zinc plating can be applied in varying thicknesses, with thicker coatings typically providing greater corrosion resistance.

In summary, while chromium, nickel, and zinc plating are all surface coating processes, they serve different purposes, offer different appearances, and have distinct advantages based on the desired properties of the coated parts. The choice of plating method depends on the specific requirements of the application.

What Surface Effect does Blue Zinc Plated Stainless Steel Parts Exhibit?

Blue zinc plating, when applied to stainless steel components, creates a distinctive surface effect that combines the inherent qualities of stainless steel with the added benefits of the blue zinc passivation. Here’s what you can expect in terms of the surface effect:

Corrosion Resistance: Stainless steel is renowned for its excellent corrosion resistance due to the presence of chromium in its composition. When combined with blue zinc plating, this corrosion resistance is further enhanced. As a result, the surface remains highly resistant to rust and corrosion, even in challenging environments.

Blue Tint: The most noticeable effect of blue zinc plating on stainless steel is the blue tint that is imparted to the surface. This blue hue is a result of the passivation process applied after zinc plating. It adds an aesthetically pleasing touch to the stainless steel while maintaining its metallic luster.

Gloss and Shine: Stainless steel already has a natural shine, and the addition of blue zinc plating enhances this quality. The surface appears glossy and reflective, contributing to a polished and attractive appearance.

Smooth Texture: Blue zinc plating typically results in a smooth and uniform surface texture. This smoothness is not only visually appealing but also contributes to the tactile quality of the coated stainless steel.

Durability: Stainless steel is known for its durability and longevity, and blue zinc plating complements these properties by providing an additional layer of protection. This durability ensures that the surface effect remains intact even in demanding applications.

Versatility: Blue zinc-plated stainless steel is suitable for a wide range of applications where both corrosion resistance and aesthetics are essential. This includes architectural elements, decorative hardware, marine components, and more.

In summary, blue zinc-plated stainless steel combines the natural qualities of stainless steel with the added benefits of corrosion resistance and an attractive blue tint. The resulting surface effect is visually appealing, durable, and well-suited for various applications where both functionality and appearance are paramount.

Blue Zinc Plating and Other Surface Treatments: Differences, Finishes and Cost Comparison

Blue zinc plating is just one of several surface treatment options available for metal components. To better understand how it compares to other surface treatments in terms of differences, surface effects, and cost considerations, let’s examine it alongside a few common alternatives:

1. Blue Zinc Plating vs. Clear Zinc Plating:

Difference: The primary difference between these two is the passivation step that adds a blue-tinted protective layer to blue zinc plating. Clear zinc plating lacks this blue passivation layer but still provides corrosion resistance.

Surface Effect: Blue zinc plating has a distinctive blue tint, while clear zinc plating maintains a silver-gray appearance similar to the natural color of zinc.

Cost Comparison: Clear zinc plating is often slightly more cost-effective than blue zinc plating due to the absence of the passivation step.

2. Blue Zinc Plating vs. Galvanization (Hot-Dip Galvanizing):

Difference: Galvanization involves immersing steel or iron components in molten zinc, creating a thicker and more robust zinc layer compared to zinc plating.

Surface Effect: Galvanized coatings typically have a matte gray or dull appearance. They lack the blue tint of blue zinc plating.

Cost Comparison: Galvanization is generally more expensive than zinc plating, but it provides superior corrosion protection for outdoor and structural applications.

3. Blue Zinc Plating vs. Powder Coating:

Difference: Powder coating involves applying a dry powder that adheres to the component’s surface and is then cured.

Surface Effect: Powder coatings can achieve various colors, including blue, but they do not have the same reflective properties as blue zinc plating. The surface is typically smoother and more even.

Cost Comparison: Powder coating costs can vary depending on factors such as color choice and material preparation. It can be competitive with blue zinc plating.

4. Blue Zinc Plating vs. Chrome Plating:

Difference: Chrome plating is a process where a layer of chromium is applied to a component’s surface.

Surface Effect: Chrome plating provides a highly reflective, mirror-like finish, whereas blue zinc plating has a blue-tinted appearance.

Cost Comparison: Chrome plating is typically more expensive than blue zinc plating due to the additional steps and materials involved.

5. Blue Zinc Plating vs. Anodizing (For Aluminum):

Difference: Anodizing is used primarily for aluminum surfaces and involves an electrochemical process that forms a protective oxide layer.

Surface Effect: Anodized aluminum can achieve various colors but has a matte or satin finish. It lacks the blue tint of blue zinc plating.

Cost Comparison: Anodizing costs can vary depending on color and complexity. It may be comparable to or slightly more expensive than blue zinc plating.

In summary, the choice of surface treatment depends on the specific requirements of the application. Blue zinc plating offers a unique appearance and corrosion resistance but may not be suitable for all scenarios. Consider factors like cost, aesthetics, and performance when selecting the most appropriate surface treatment for your metal components.

Blue Zinc Plating Surface Treatment Application

Blue zinc plating, with its distinctive blue-tinted appearance and enhanced corrosion resistance, finds application in various industries and for a range of purposes. Here are some common applications of blue zinc-plated surfaces:

Automotive Industry:

Blue zinc-plated fasteners, bolts, and nuts are frequently used in the automotive industry. They provide both corrosion resistance and a visually appealing finish for various vehicle components.

Construction and Building Materials:

Blue zinc-plated structural steel elements, such as bolts and brackets, are used in construction. The corrosion resistance helps ensure the longevity of these critical components.

Hardware and Fasteners:

Blue zinc-plated hardware, including screws, nails, and hinges, is used in a wide range of applications. The surface treatment prevents rust and enhances durability.

Electrical and Electronics:

Components in the electrical and electronics industry often benefit from blue zinc plating, which provides a protective barrier against corrosion without compromising electrical conductivity.

Agricultural Equipment:

Farm machinery and equipment use blue zinc-plated parts to withstand outdoor conditions and exposure to moisture, ensuring extended service life.

Marine and Coastal Applications:

In marine environments, where saltwater exposure is common, blue zinc plating helps prevent corrosion on components like boat hardware and dock structures.

Decorative Hardware:

Blue zinc-plated hardware is used for decorative purposes, such as furniture fittings and architectural elements, where both aesthetics and corrosion resistance are essential.

Consumer Goods:

Blue zinc-plated components can be found in everyday consumer goods like bicycles, appliances, and DIY tools.

General Manufacturing:

Many manufacturing processes across various industries incorporate blue zinc-plated parts, benefiting from their combined strength and protection against corrosion.

Aftermarket Automotive Parts:

The aftermarket automotive industry often uses blue zinc-plated parts for replacement and upgrade purposes, particularly in areas where aesthetics play a role.

Mechanical and Industrial Equipment:

Industrial machinery and mechanical equipment often include blue zinc-plated components to ensure they withstand harsh working environments.

Furniture and Fixtures:

Blue zinc-plated hardware and fixtures are used in furniture manufacturing and home improvement projects to provide both functionality and an appealing appearance.

Renewable Energy:

In the renewable energy sector, such as solar and wind power, blue zinc-plated parts are utilized in various components to ensure they withstand outdoor conditions.

Aviation and Aerospace:

In aviation and aerospace applications, where high-performance materials are crucial, blue zinc plating can provide corrosion protection without adding excessive weight.

These are just a few examples of the diverse range of applications for blue zinc-plated surfaces. Its ability to combine corrosion resistance with an attractive appearance makes it a versatile choice in various industries where both functionality and aesthetics are important.

Problems and Precautions for Blue Zinc Plated Stainless Steel Parts

When working with blue zinc-plated stainless steel parts, there are specific issues and precautions to be aware of to ensure the best results and performance. Here are some common considerations and precautions:

1. Corrosion Resistance: While blue zinc plating enhances the corrosion resistance of stainless steel, it’s essential to select the appropriate type of stainless steel for the intended environment. Stainless steel grades vary in their resistance to specific corrosive agents, so consult with a materials expert to ensure compatibility.

2. Surface Damage: The blue zinc-plated surface can be susceptible to damage from abrasive materials, harsh chemicals, or rough handling during transport and installation. Take care to protect the plated surface from such potential sources of damage.

3. Surface Preparation: Proper surface preparation before blue zinc plating is critical. Any contaminants, rust, or scale on the stainless steel surface can affect the adhesion and quality of the zinc plating. Thorough cleaning and pretreatment are essential.

4. Thickness Requirements: Depending on the application and the level of corrosion protection needed, the thickness of the zinc plating should be considered. Ensure that the plating thickness meets the requirements specified for the particular application.

5. Compatibility with Other Materials: In assemblies where blue zinc-plated stainless steel parts are combined with other materials, ensure compatibility to prevent galvanic corrosion. Use insulating materials or appropriate coatings as needed.

6. Handling and Storage: During handling and storage, protect blue zinc-plated parts from moisture, extreme temperatures, and abrasive contact. Moisture can lead to corrosion, while temperature extremes can affect the appearance and performance of the plating.

7. Maintenance: Regular inspection and maintenance are essential to ensure that the blue zinc plating continues to provide corrosion resistance. Inspect for any signs of damage or corrosion, and address issues promptly to prevent deterioration.

8. Threaded Fasteners: When using blue zinc-plated stainless steel threaded fasteners, be cautious about galling (thread seizing) during assembly. Proper lubrication or the use of anti-galling compounds can help prevent this issue.

9. Cleaning and Care: Clean blue zinc-plated surfaces with mild, non-abrasive cleaning solutions and soft materials to avoid damaging the plating. Harsh chemicals and abrasive cleaning tools can compromise the surface appearance and protection.

10. Environmental Considerations: Be aware of environmental regulations regarding the disposal of blue zinc plating solutions and waste. Ensure compliance with local environmental guidelines and consider eco-friendly alternatives if available.

11. Coating Integrity: Regularly inspect the integrity of the blue zinc plating. Any signs of wear, flaking, or deterioration should be addressed promptly to maintain corrosion resistance.

By taking these issues and precautions into account, you can maximize the performance and longevity of blue zinc-plated stainless steel parts in your applications while ensuring they meet the desired aesthetic and functional requirements.

Conclusion

Do you know how to choose the right finish for your project? CNCMF has 15 years of experience in surface treatment experts to choose the appropriate surface treatment for you to improve the surface texture and performance of stainless steel CNC machined parts.

Learn about the surface treatment process, advantages and applications of blue zinc plating according to this article. If you want to know more about blue zinc plating surface treatment, please contact us immediately. CNCMF can provide a wide range of CNC machining and manufacturing capabilities and surface treatment services for stainless steel, aluminum, titanium, copper and other materials. Our team of professional engineers can choose the appropriate surface treatment for you to meet all your stainless steel CNC machined parts production needs and obtain Best, competitive price. Why not give CNCMF a try and contact us now to get a quote.

Blue zinc plating FAQs

Certainly! Here are some common questions and answers regarding blue zinc plating:

1. What is blue zinc plating?

Blue zinc plating is a surface treatment process used to apply a layer of zinc onto metal components. It includes a passivation step that imparts a distinctive blue tint to the zinc coating.

2. What are the benefits of blue zinc plating?

Blue zinc plating offers several advantages, including enhanced corrosion resistance, an attractive appearance, improved durability, and versatility in various applications.

3. Is blue zinc plating only for stainless steel?

No, blue zinc plating can be applied to various metals, including steel and iron. However, it is particularly popular when combined with stainless steel, as it provides added corrosion protection to this already corrosion-resistant material.

4. What are the common applications of blue zinc-plated parts?

Blue zinc-plated parts are used in industries such as automotive, construction, hardware, electronics, marine, agriculture, and more. They are suitable for any application where corrosion resistance and aesthetics are essential.

5. How does blue zinc plating enhance corrosion resistance?

Blue zinc plating creates a barrier between the metal substrate and the environment, preventing corrosive agents from reaching the base metal. The passivation layer further improves corrosion resistance.

6. Can blue zinc-plated parts be used outdoors?

Yes, blue zinc-plated parts are suitable for outdoor applications, especially in moderate to mildly corrosive environments. However, for severe outdoor exposure, consider thicker coatings or additional protective measures.

7. Does blue zinc plating affect the dimensions of parts?

Blue zinc plating adds a thin layer to the surface, which can slightly affect the dimensions of threaded or precision components. It’s essential to account for this when designing parts.

8. How should I clean and maintain blue zinc-plated parts?

Clean blue zinc-plated surfaces with mild, non-abrasive cleaning solutions and soft materials to avoid damaging the plating. Regular inspections are essential to detect any signs of wear or corrosion for timely maintenance.

9. Can I paint or powder coat over blue zinc-plated surfaces?

Yes, blue zinc-plated surfaces can be painted or powder coated for additional protection or to achieve specific colors. Proper surface preparation is essential for adhesion.

10. Are there any environmental considerations with blue zinc plating?

Yes, be mindful of environmental regulations regarding the disposal of blue zinc plating solutions and waste. Ensure compliance with local environmental guidelines and consider eco-friendly alternatives if available.

These FAQs should provide you with a good understanding of blue zinc plating, its benefits, applications, and maintenance considerations. If you have specific questions or require more detailed information, consult with a plating professional or supplier.