A high-quality part is strictly inspected, and we know exactly how many parts we need to manufacture. Now we need to make these parts, should we take the traditional route? Should we inject the mold? The highest sales volume tends to bring you the lowest price tag. However, if you are thoughtful, the production environment usually brings other things, as well as a lot of cost control.

These are very common problems. They all affect the margin in different ways. I don’t know what you think, but I have never seen any boss who would ask us to reduce the profit of the product. Let us erode our profits. If you are at this stage, many decisions will come down to what you have already done. Where is the prototype manufacturer? Do they provide production parts? How is your prototype? Compared with the production stage, it is very common for product developers to cooperate with different suppliers in the prototype manufacturing stage, which undoubtedly brings complexity and risk to this stage of the process.

Qualification

The qualification or verification process you choose may require consideration of direct or indirect costs. First of all, these processes usually require more time and money to complete. The cost is easy to calculate and you will get the corresponding quotation. However, there are always many uncertain factors affecting us, and it may take several weeks for you to To determine the indirect cost of the product, have you spent a few more weeks of money? Maybe you don’t understand. Let me put it another way. If I enter the market a few weeks earlier, how much more revenue can I generate? On-demand production helps you turn these traditional challenges into opportunities.

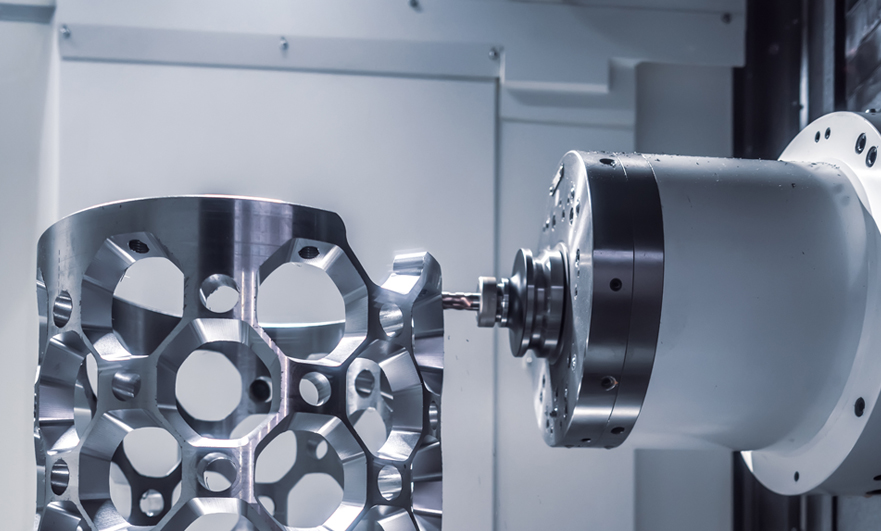

Manage the number of parts with digital manufacturing

Sometimes, your predictive ability can be boiled down to the degree of innovation of the product. You have many previous iterations that you can use as a benchmark, and if that is the case, this may not be a huge challenge for you. However, if it is really difficult for you to predict your product sales, you may need to be vigilant. Minimum order quantity.

In fact, once it is clear that you can bring “prototype” parts to the market, you may find reasons to simply postpone the production of steel tools.

One of the reasons may be that when you switch to production molds, you can reduce upfront expenses by ordering a smaller number of parts than you promised. This is especially meaningful if there is any uncertainty in the market demand for your new product. This is a way to go beyond mere market testing and actually release your product to the market and measure the response before committing to full production.

If the market’s response to your product indicates a need for “adjustment,” you can quickly make changes and return to the market with an improved product within a few days. Enter digital manufacturing. According to our on-demand production model, we know that managing fluctuations in demand is a key challenge facing our customers, and we will never lock you in MOQ. This way you can increase production based on demand and ultimately optimize profit margins by eliminating inventory and storage costs.