What Is a Proof of Concept?

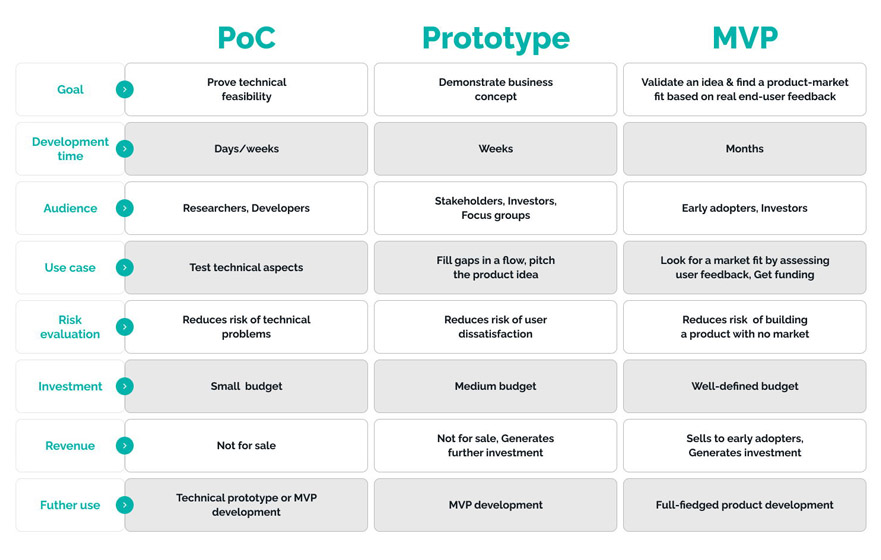

POC stands for “Proof of Concept.” It’s a preliminary demonstration or exercise aimed at validating the feasibility of an idea, concept, or technology. A POC is typically a small-scale project or effort undertaken to test a specific approach or hypothesis to determine whether it can be practically implemented.

Key features of a POC include:

Feasibility Testing: It’s primarily focused on determining if a concept or technology is viable and can be executed practically.

Small-scale and Experimental: POCs are often small in scope, serving as an experimental test rather than a fully developed product or solution.

Focus on Viability: It emphasizes the technical or conceptual validation of a specific idea rather than creating a comprehensive or market-ready product.

Exploratory Nature: POCs may involve research, testing, or creating a simple model to show how a proposed concept or technology could work.

Early Stage in Product Development: POCs are typically one of the first steps in the development process, undertaken before moving to more comprehensive stages such as prototyping or building a minimum viable product (MVP).

In essence, a Proof of Concept is a preliminary step used to determine the practicality, feasibility, and potential success of an idea or concept before investing more resources into its development.

What Is a Prototype?

A prototype is a preliminary version or sample of a product or system that is developed to visualize or demonstrate its basic features, functionalities, and design. It serves as an early representation of the final product, allowing stakeholders to assess and understand its potential.

Key characteristics of a prototype include:

Visualization: It provides a tangible representation of the product, showcasing its appearance, layout, and user interface design.

Functional Representation: Prototypes often simulate core functionalities or specific features of the final product to test and demonstrate its behavior.

Developmental Stage: Prototypes are part of the development process, serving as an intermediate step between initial concepts and the final product.

Feedback and Iteration: They enable gathering feedback from stakeholders or users to refine and improve the product’s design and functionalities.

Variability: Prototypes can be low-fidelity or high-fidelity, representing the product’s design at different levels of detail and functionality.

Prototypes can be physical models, mock-ups, wireframes, or interactive software that closely resemble the final product in appearance and function to varying degrees. They are used to communicate design ideas, test functionalities, and identify potential improvements before proceeding to the final product development phase.

What Is a Minimum Viable prototype?

A Minimum Viable Prototype (MVP) is a simplified and basic version of a product that includes just enough features to showcase its core functionality. It’s a fundamental concept in product development, primarily used in software and hardware industries. The aim of an MVP is to test the viability of a product idea with minimum resources and investment.

Key characteristics of an MVP include:

Core Functionality: It focuses on essential features required for the product to function and provide value to the users.

Limited Scope: It omits non-essential functionalities and features to keep the prototype simple and easy to develop.

Quick Development: The focus is on rapid development to get the prototype into the hands of users for early feedback and validation.

Testing and Learning: It’s designed for testing assumptions, understanding user needs, and learning from user feedback to iterate and improve the product.

Cost and Resource Efficiency: It aims to reduce development costs and resource allocation, allowing for a quick assessment of market demand and acceptance.

The primary goal of an MVP is to validate the product concept with minimal resources before further investment is made in its full-scale development. It helps in gaining insights from users, understanding market demands, and refining the product based on real-world feedback and user behavior.

Summary

Proof of Concept (POC):

A POC is a preliminary demonstration to test the feasibility of an idea or technology.

It’s a small-scale experiment to validate the practicality of a concept or approach.

Prototype:

A prototype is an early version or sample of a product that visualizes its design and features.

It represents the basic functionalities and appearance of the final product, allowing stakeholders to assess its potential.

Minimum Viable Product (MVP):

An MVP is the initial version of a product that includes essential features for testing in the market.

It’s developed with the minimum functionalities required to solve core user needs and gather feedback for further improvements.

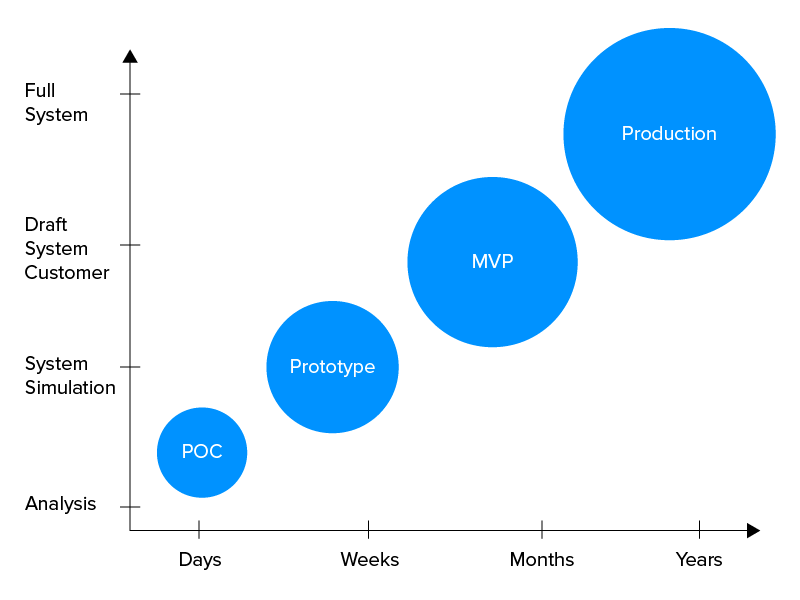

These terms represent distinct stages or versions in the product development process, from validating an idea’s feasibility (POC) to creating a tangible representation (prototype) and finally, testing the core features in the market (MVP). Each stage serves a specific purpose in product development, catering to different aspects of the product’s evolution and refinement.

Explore the key stages in product development, from validating initial concepts to refining market-ready products. This comprehensive guide unveils the significance of Proof of Concept (POC) as a feasibility test, Prototyping as a visualization tool, and Minimum Viable Product (MVP) as the essential market-ready version.

Find the right CNC machining factory

Are you looking for the right CNC machining factory? CNCMF has 15 years of experience in surface treatment experts to choose the appropriate surface treatment for you to improve the surface texture and performance of CNC parts.

Understand what is POC, Prototype and MVP based on this article? If you want to know more about CNC machining parts, please contact us immediately. CNCMF can provide a wide range of CNC machining and manufacturing capabilities and surface treatment services for steel, aluminum, titanium, copper and other materials. Our team of professional engineers can choose the appropriate surface treatment for you to meet all your CNC machined parts production needs and obtain the best results. Best, competitive price. Why not give CNCMF a try and contact us now to get a quote.