What are the common shapes of CNC machined parts?

In CNC machining, various common shapes and geometries can be produced based on the specific design requirements of the parts. Some of the typical shapes and forms of CNC machined parts include:

Cylindrical: These parts have a circular cross-section and can be simple cylinders or more complex shapes with varying diameters.

Rectangular: Parts with rectangular or square profiles are common, often used in applications like frames, brackets, and panels.

Circular: Circular parts have a consistent radius throughout their structure, making them suitable for components like bearings, bushings, and shafts.

Complex Contours: CNC machining allows for the creation of intricate and custom shapes with complex contours, such as aerospace components and medical implants.

Conical: Conical parts have a tapered or cone-like shape and are used in applications like nozzles, funnels, and certain connectors.

Spherical: Spherical parts have a curved, globe-like shape and are utilized in applications like ball bearings and optical lenses.

Irregular Shapes: Some CNC machined parts have irregular or asymmetric shapes, which can be found in specialized industries like automotive or aerospace.

Prismatic: Prismatic parts have flat, planar surfaces and are often used in assemblies where multiple components need to fit together precisely.

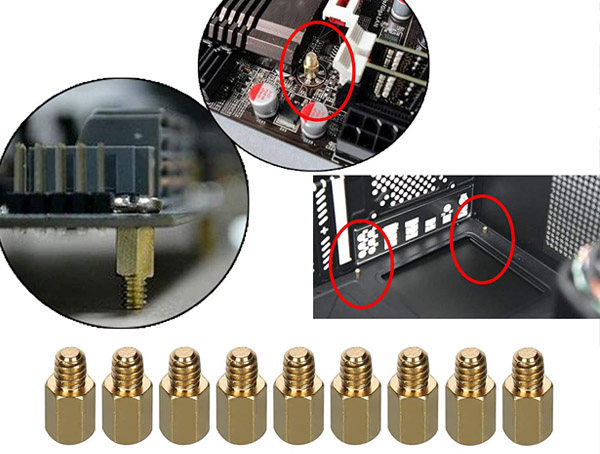

Threaded: Threaded components have threads on their surfaces, commonly used in fasteners like screws, bolts, and nuts.

Rotational Symmetry: Parts with rotational symmetry have features that repeat evenly around an axis, making them suitable for applications like impellers and gears.

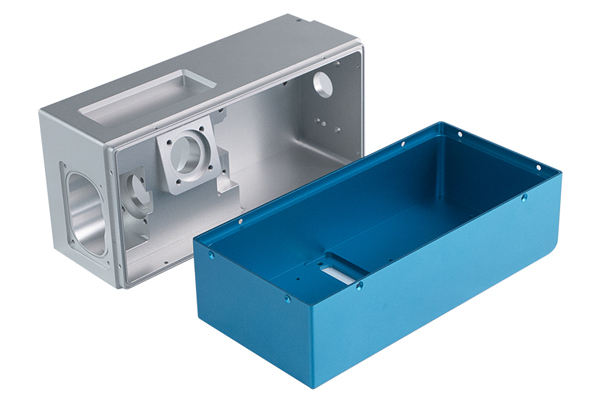

Hollow Structures: CNC machining can create parts with internal voids or cavities, which are commonly found in fluidic systems, heat exchangers, and lightweight structures.

Curved Profiles: Parts with curved profiles can be produced for applications like aerodynamic components in the aerospace industry.

Flanges and Joints: CNC machining is used to create flanges, joints, and connections for various engineering applications.

Blades and Vanes: Blades and vanes with specific airfoil profiles are produced for applications like turbines and compressors.

Custom Designs: CNC machining allows for the production of highly customized and unique parts tailored to specific engineering needs.

These are just a few examples of the diverse range of shapes and geometries that can be manufactured through CNC machining. The versatility and precision of CNC machining technology make it suitable for a wide array of industries and applications, accommodating various part shapes and sizes.