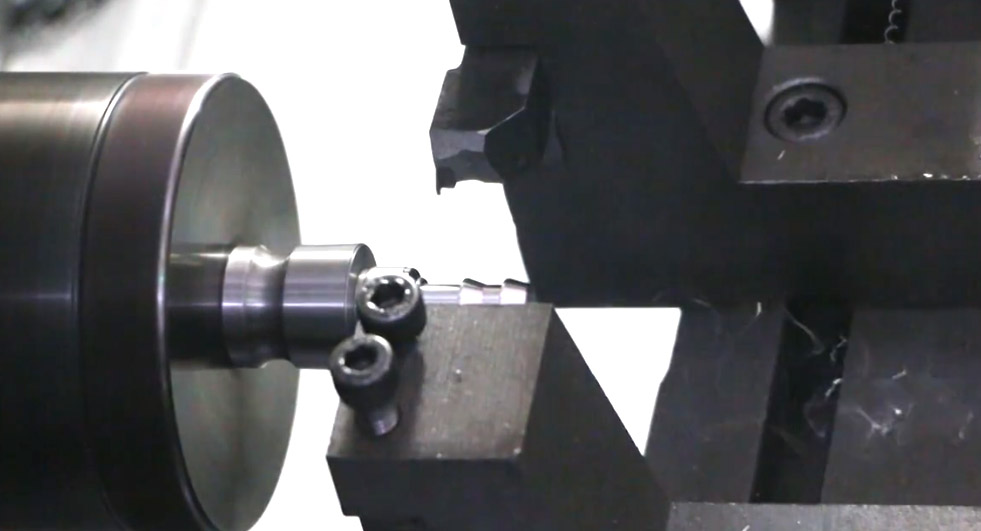

When we are milling turning machining stainless steel parts, we should all encounter the same problem: stainless steel CNC machining parts are difficult to process; the reason for the difficulty in machining lies in the choice of tools. What material is used for the tool, the reason why stainless steel is difficult to process and the solution:

For CNC turning stainless steel on automatic lathes, commonly used carbide tool materials include: YG6, YG8, YT15, YT30, YW1, YW2 and other materials; commonly used high-speed steel tools include: W18Cr4V, W6M05Cr4V2AL and other materials.

There are several common difficulties in the milling turning machining of stainless steel parts:

1. Large cutting force

Stainless steel has high strength, large tangential stress and large plastic deformation CNC milling, so the cutting force is large. However, the thermal conductivity of the material is extremely poor, leading to an increase in the cutting temperature. High temperatures tend to concentrate in the narrow area close to the cutting edge of the tool, accelerating the wear of the tool.

The high cutting strength is mainly due to the inconsistent strength of stainless steel of different materials, so the corresponding force during cutting is relatively large, and it is not easy to be plastic. When choosing drilling, boring and other processes, try to choose a process with higher processing material strength, so that it is not easy to cause deformation of the stainless steel, and it can reduce the cutting strength during the cutting process.

2. High cutting temperature

From the perspective of heat conduction, the stainless steel material itself is not conducive to heat conduction. Milling turning machining the cutting process, the machining process and the workpiece must be in contact, resulting in high machining temperatures and increased tool wear. It can be solved by the heat treatment method of “Solid Solution Water Toughening Treatment”. Without changing the physical state of the raw material, the structure of the processed material can be fine-tuned to increase the temperature during processing.

3. Severe hardening during stainless steel milling turning machining

Austenitic stainless steel and some high-temperature alloy stainless steels are both austenitic structures, which have a high tendency of work hardening during cutting, which is usually several times that of ordinary carbon steel. The tool cuts in the work hardened zone, shortening the tool life.

4. Easy to stick to the knife

Both austenitic stainless steel and martensitic stainless steel have the characteristics of strong chip toughness and high cutting temperature during processing. When the hard chips flow through the rake face, adhesion phenomena such as adhesion and welding will occur, which will affect the surface roughness of the processed parts.

When CNC milling turning machining several kinds of stainless steel, due to material impurities, there will be a certain degree of adhesion between the processed material and the workpiece. Even if the quality of the processed finished parts is poor, the surface is easy to wear, and the sticking knife will cause great damage to the tool.

5. Accelerate tool wear

The above-mentioned materials generally contain high melting point elements, high plasticity and high cutting temperature, which accelerate tool wear, frequent wear and tool replacement, thereby affecting production efficiency and increasing tool usage costs.