In the CNC machining process, the strength of the workpiece is of concern to many users and CNC machining manufacturers. For example, the aluminum alloy that we often come into contact with has relatively light weight and high precision, and is very popular in the automotive industry. It can meet the design and use requirements of lightweight automobiles. If the hardness of the parts does not meet the user’s requirements, such products can only be treated as waste products.

For Many CNC Machining Factories, the Key Factors Affecting the Hardness of Parts are the Following Three Points:

1. The influence of the processing material, the raw material of the product is an important factor that directly affects the hardness of the CNC machined parts. When the customer chooses the processing material, the strength of the part is basically determined. If the hardness of the processed material is relatively small, the plasticity is relatively large. Before CNC machining parts, they must communicate with engineers and technicians;

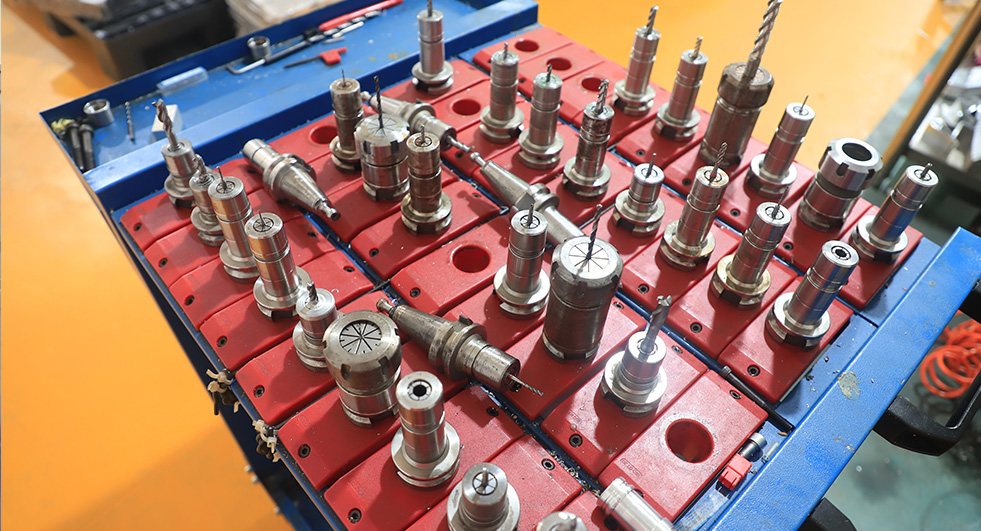

2. Affected by the shape of the tool. Precision parts machining factory know that CNC machining tools are indispensable to realize the conversion from blanks to parts. CNC machining tool rake angle, cutting edge fillet and tool surface wear will affect the hardened layer of the part surface; and the hardness of the surface and deep layers of the part will decrease with the tool rake angle, increasing the wear of the cutting edge and back.

3. The influence of cutting volume. The transformation of feed speed and cutting speed will also affect the strength of the part during processing. When the economic speed of the tool increases, the probability of plasticity will be higher and the surface hardness will also be affected. If the cutting speed of the tool is increased, the contact time between the tool and the workpiece around the part will be shorter, the probability of plastic deformation will also be reduced, and the hard layer and hardness will be reduced;

Therefore, in the processing of precision parts, as long as the above factors are handled well, the CNC machining factory will no longer have to worry about the strength of the parts. CNCMF focuses on customized processing and mass production of high-quality precision CNC machined parts. 11 years of experience in CNC machining. The product range is very wide, and there are many types of processing. Support CNC machining, turning machining, four-axis five-axis linkage machining services, etc.