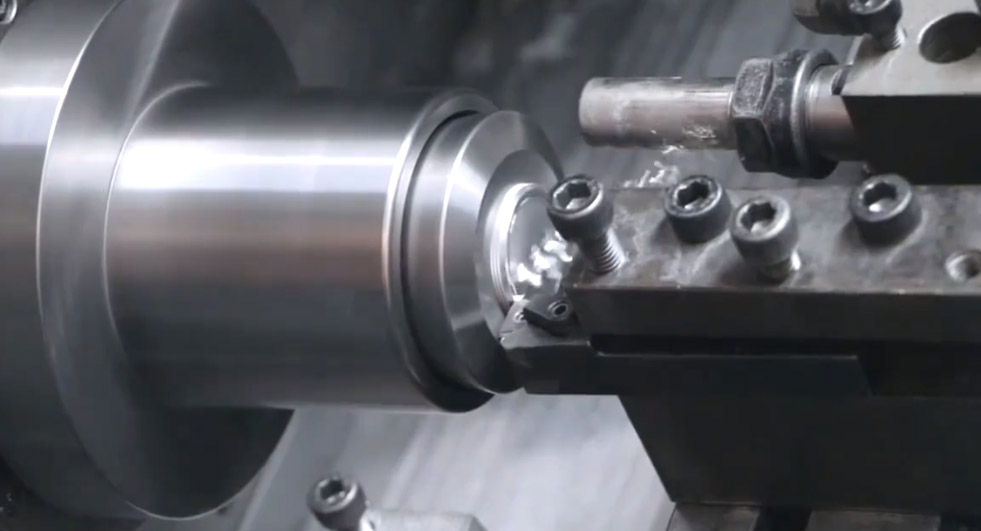

There are many factors that cause deformation of aluminum parts after CNC machining, which are closely related to the material, shape and manufacturing conditions of the parts. There are mainly deformation caused by the internal stress of the blank, cutting force and deformation caused by cutting heat. Are there any technical measures to reduce the deformation of aluminum parts due to the deformation caused by the clamping force? Let’s take a look with aluminum CNC machining turning parts manufacturers today:

1. Reduce the internal stress of the blank

The principle of natural or artificial aging and vibration can be used to partially consume the internal stress of the blank. First machining is also a more effective machining method. For the blank, due to the relatively large margin, the deformation after aluminium CNC machining turning will be relatively large. If the excess part of the blank is machined first, and the margin is reduced, not only can the machining deformation of the subsequent process be reduced, but also a part of the internal stress can be released after machining;

2. Improve the cutting ability of the CNC machining turning tool

The tool material and several parameters affect the cutting force and cutting heat. It is important to choose the right tool to reduce the deformation caused by aluminum CNC machining and turning parts;

A. Reasonable selection of parameters

a、The rake angle, while maintaining the strength of the cutting edge, choose a larger rake angle, which can not only grind a sharp edge, but also reduce cutting deformation, make chip evacuation smoother, reduce cutting force and temperature, and do not use it. Negative Rake Corner Knife.

b、The size of the relief angle is directly related to the wear of the flank surface and the quality of the machined surface. Cutting thickness is an important condition for selecting the relief angle. During rough milling, due to the larger feed rate, heavier cutting load, and larger heat, better heat dissipation conditions of the tool are required, so the clearance angle should be selected smaller. When finishing milling, the cutting edge should be sharp to reduce the friction between the tool and the machined surface and reduce elastic deformation, so the relief angle should be larger;

c、Helix angle, in order to make the milling more stable and reduce the milling force, the helix angle should be larger;

d、The entering angle, appropriately reducing the entering angle can improve the heat dissipation conditions and reduce the average temperature of the processing area;

B. Improve the structure of the tool

a、Reduce the number of teeth of the milling cutter and increase the chip space. Due to the large plasticity of aluminum, the cutting deformation is large during machining, and a large chip flute is required. Therefore, the bottom radius of the chip flute should be larger, and the number of teeth of the milling cutter should be smaller;

b、When sharpening the teeth, the edge roughness of the teeth should be less than Ra=0.4um. Before using a new knife, you should lightly polish the front and back of the tooth with a fine oil stone to eliminate the slight jagged lines and burrs remaining during the tooth grinding, which can reduce the cutting heat and reduce the cutting deformation;

c、Strictly control tool wear standards. After the tool is worn, the cost of surface roughness increases, the cutting temperature increases, and the deformation of the aluminium cnc machining turning parts increases. Therefore, in addition to selecting tool materials with better wear resistance, the tool wear standard needs to be less than 0.2mm, otherwise chips are prone to occur. When cutting, the temperature of the parts should be controlled within 100 degrees to prevent deformation;

3. Improve the clamping method of aluminium cnc machining turning parts

For some thin-walled aluminum CNC machining turning parts with poor rigidity, the following methods can be used to clamp to reduce deformation

a、For thin-walled bushings, if three-jaw self-centering chucks or spring chucks are used to clamp from the radial direction, once the parts are loosened after CNC machining, they will inevitably be deformed. At this time, the inner hole of the part should adopt the method of machining the axial end face with better rigidity, self-made threaded mandrel, sleeve it into the inner hole of the part, and tighten the end face with the modified end face. When machining the outer circle, it can avoid the clamping caused by Deformation to obtain satisfactory CNC machining accuracy;

b、When CNC machining turning thin-walled aluminium parts, it is best to use a vacuum suction cup to obtain a more evenly distributed clamping force, and then use a smaller cutting amount to process, which can well prevent the deformation of the parts;

The filling method can also be used to increase the process rigidity of thin-walled parts, and to fill the inside with a medium to reduce deformation during clamping and cutting. For example, 3% to 6% of potassium nitrate urea melt is used to fill the workpiece. After CNC machining and turning, soak the parts in water or alcohol to dissolve the filling and pour it out;

4. Reasonable arrangement of machining procedures

During high-speed cutting, due to the large machining allowance, the machining is intermittent, and vibration is prone to occur during the cutting process, which affects the machining accuracy and surface roughness. Therefore, CNC high-speed machining turning parts can generally be divided into rough machining, semi-finish machining, clear corner machining and precision CNC machining. For parts with high precision requirements, sometimes it is necessary to perform secondary semi-precision machining, and then perform precision machining. After rough machining, the parts can be cooled naturally to eliminate internal stress caused by rough machining and reduce deformation. The margin after rough machining should be greater than the deformation, generally 1-2mm. During precision machining, the surface of the part must be processed uniformly, generally 0.2-0.5mm. During the machining process, the tool must be kept in a stable state, so as to reduce cutting deformation, obtain a good surface machining quality, and ensure the aluminium cnc machining turning parts services accuracy of the product;

The above are the measures to reduce the deformation of aluminum parts. Hope this article can be helpful to you. CNCMF focuses on high-precision aluminum machining parts services. If you have related product requirements, please feel free to contact vmt, we will provide you with one-stop aluminium cnc machining services.