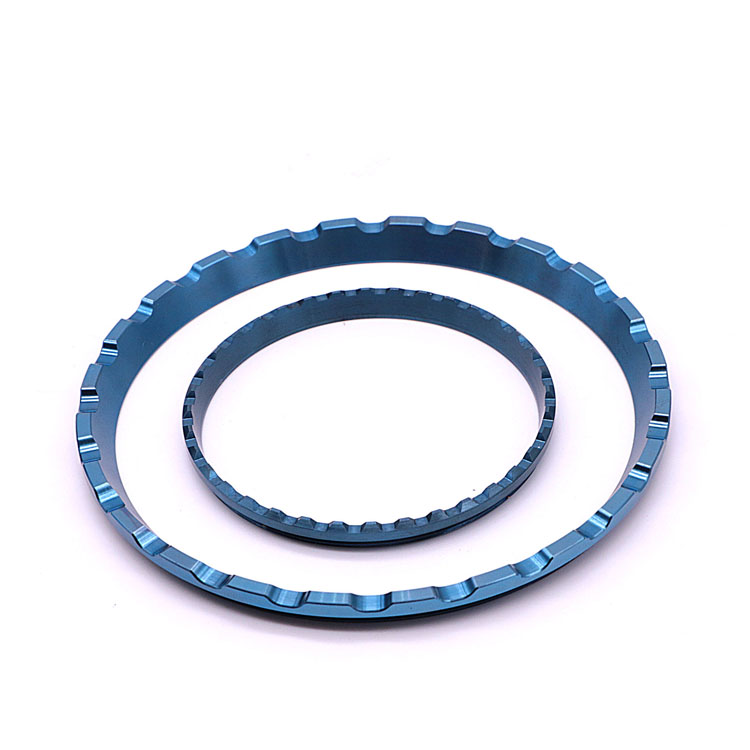

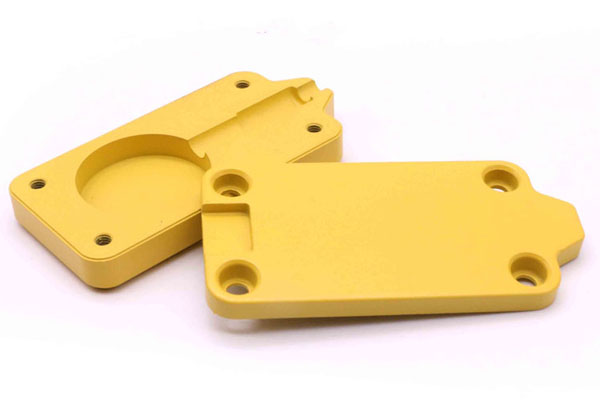

With the improvement of people’s aesthetics, metal texture is becoming more and more popular. However, the cost of metal materials is relatively high, which limits the application of some daily necessities. Plastics are lightweight and have some properties that can be used in some daily necessities, but the surface texture of plastics is not beautiful enough and can easily make them feel cheap. So how can plastics have a metallic texture, be a better substitute for metal materials, and combine the advantages of the two? The following are several surface metallization processes for plastic CNC machined parts. Let us take a look at what is the surface metallization process for plastic CNC machined parts.

What is metallization of polymer materials? Metallization of polymer materials is to use physical or chemical means to plate a layer of metal on the surface of polymer materials, so that the surface exhibits certain properties of metal, such as electrical conductivity, magnetism, thermal conductivity, etc. . Metallized polymer materials have a metallic appearance, high coating hardness, and are easy to weld. They can replace metal products and reduce costs. At the same time, because polymer materials generally have high toughness, heat resistance, corrosion resistance, etc., metallization has a high Molecular materials perform better than ordinary metal materials. With the development of technology, metal powders, etc., can now be added to plastic resins to prepare metallized materials.

What is the plastic metallization process? Plastic metallization is basically divided into two categories, one is plastic surface metallization, and the other is plastic overall metallization. The former is divided into dry method and wet method. Dry methods mainly include physical vapor deposition and chemical vapor deposition; wet methods mainly include chemical plating, electroplating and chemical reduction.

Dry Metallization (dry coating)

1. Physical Vapor Deposition (PVD)

Physical vapor deposition (PVD) mainly includes vacuum evaporation and magnetron sputtering. The space where the film is deposited is required to have a certain degree of vacuum, so vacuum technology is the basis of physical vapor deposition.

The vacuum evaporation method refers to heating the coating material in a vacuum environment to evaporate it in a very short time and deposit it on the plastic surface to form a coating.

Advantages:

This method has fast film formation rate and high efficiency, but the bonding between the film and the substrate is poor. For this reason, plasma etching and vacuum evaporation are combined to improve the bonding force (ion plating).

Disadvantages:

Only low melting point metals like aluminum can be evaporated.

The magnetron sputtering method uses high-energy ions to bombard the target material, so that the atoms on the target surface gain enough energy to break away from the base material, leap out in the corresponding sputtering direction, and deposit on the plastic surface.

Compared with the vacuum evaporation method, the magnetron sputtering method does not require pretreatment, has stronger binding force, and can deposit a variety of metals.

2. Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a process in which reactive gases containing deposition elements are introduced into the reaction chamber, a chemical reaction occurs on the surface of the substrate, and the solid product is deposited on the surface of CNC machined parts. Some researchers have successfully deposited copper on the surface of PTFE CNC machined parts using this method.

Advantages: The chemical vapor deposition film layer is dense, has strong bonding force, relatively uniform thickness, and stable film quality.

Disadvantages: There are many factors that affect the composition and structure of the membrane (such as gas movement rate, pressure distribution, temperature, etc.), which must be strictly controlled to obtain an ideal membrane. At the same time, the reaction temperature of the traditional chemical vapor deposition method is usually very high (900~2000°C), which can easily lead to deformation and structural changes of CNC machined parts.

Wet Coating

Since electroless plating, electroplating, chemical reduction and other methods are all performed in solution, it is called wet plating.

1. Electroless Plating

Electroless plating is currently the most widely used plastic metallization processing method. Based on the principle of redox reaction, a strong reducing agent is used in a solution containing metal ions to reduce metal ions into metal and deposit them on the surface of various materials to form a dense coating. Methods.

Advantage

1) The plating process does not require external power supply and the equipment is simple;

2) It has good throwing plating ability, and even plated parts with complex shapes and inner holes and cavities can obtain uniform coatings;

3) The coating is dense and has low porosity;

4) Applicable to a wide range of base materials, coatings can be deposited on metals, non-metals and organic substances;

5) It is easy to prepare amorphous alloys and certain films with special functions, such as magnetic, optical, electrical and other functional coatings.

Disadvantages: The plating solution has short life, poor stability, and slow plating speed.

2.Electroplating

Electroplating is a process that uses the principle of electrolysis to plate a thin layer of other metals or alloys on the surface of certain metal CNC machined parts. It is a process that uses electrolysis to attach a metal film to the surface of metal or other material parts.

Advantages: Electroplating can enhance the corrosion resistance of metal (coated metals are mostly corrosion-resistant metals), increase hardness, prevent wear, improve conductivity, smoothness, heat resistance and beautiful surface.

Disadvantages: It requires the use of chromium metal derivatives and nickel that are harmful to the environment. The plastic currently used most for electroplating is ABS, followed by PP. In addition, there are also methods for successful electroplating of PSF, PC, PTFE, etc., but they are more difficult.

3.Chemical Reduction Method

The main steps of preparing polymer metallized surface by chemical reduction method:

1) Dissolve the polymer containing polar groups and the metal salt that can form a complex with it in the solvent to form a uniform solution.

2) The solution is evaporated to form a sample.

3) Place the sample in the reducing solution to form a conductive metal layer on the sample surface through chemical reduction reaction.

Advantages: The chemical reduction method solves to a certain extent the problems of poor surface bonding, poor durability, high cost of coating equipment, complex processes, etc., and has a lot of room for development.

Other Metallization Coating Methods

1. Metallic Paint Coating

Coatings made of silver, copper, nickel, aluminum and other metal powders are used to coat plastics to metallize the plastics. In addition to giving the plastic surface a metallic decorative effect, this method can also use the conductivity of the layer as a method to make the plastic mobile phone case have shielding properties.

2. Metal Spraying

Metal spraying is a material protection technology that uses a high-speed particle flow of molten metal to spray on the surface of a substrate to produce a coating. Including arc spraying, plasma spraying, flame spraying and high-speed oxy-fuel spraying.

Advantage

1) Rich colors;

2) CNC machining in a liquid environment can achieve surface treatment of complex structures;

3) The technology is mature and can be mass produced;

4) It has unique transparency and high gloss.

Disadvantages

1) The cost is too high.

2) Metal particles and high-temperature flames in the molten state will cause damage to the surface of the polymer matrix material. Due to the high heating temperature of thermal spraying, the obtained metal coating is difficult to meet the use requirements due to oxidation and large porosity.

Therefore, cold spraying is generally used to coat metal layers on the surface of polymer-based materials. Cold spraying technology only requires a small amount of heat input, has low heating temperature and high particle flight speed, effectively preventing the thermal impact of thermal spraying. , reducing the three-dimensional distortion of the substrate surface, coating oxidation, phase change and other problems.

3.Metal Powder Composite Method

The metal powder composite method is to add special metal pigments, such as metal powder, color masterbatch, granulation materials, etc. during the plastic molding process, so that the plastic products can achieve pearlescent, metallic luster and other effects. This method can avoid some spraying processes and is a method of overall metallization of plastics. At present, some plastic companies are developing such products. The plastic particles produced can be directly used for molding. The process is simple and the cost of CNC processing is reduced.

Summary

The surface metallization process of plastic CNC machined parts can achieve a metallic appearance of plastic, turning it into fake metal. Plastic products obtained through the plastic surface metallization process have more advantages than metal materials in terms of electrical conductivity, magnetism, and thermal conductivity. However, there are still very few types of plastics that can be used for metallization. The most common ones are ABS, followed by PP, and then PSF, PC, PTFE, etc. Surface metallization of plastic CNC machined parts is still in its infancy, and its applications will be more extensive in the future.