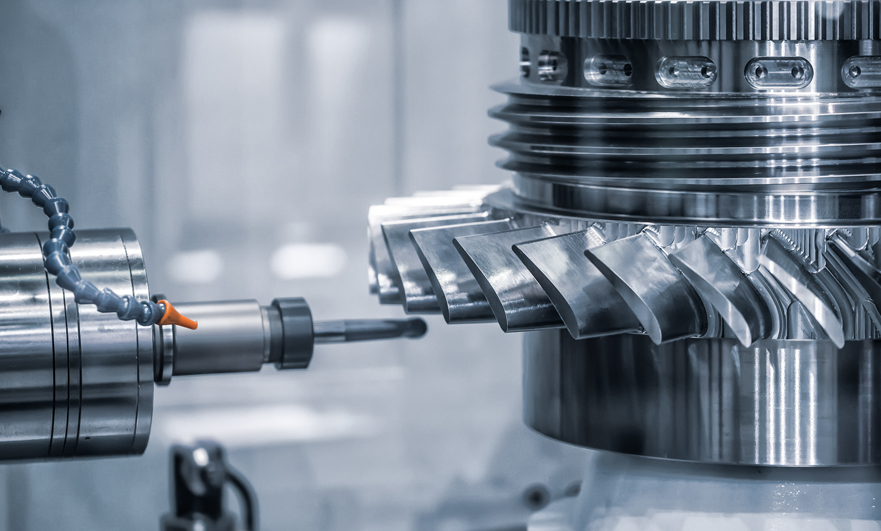

From the traditional processing industry to CNC numerical control processing, 5-axis CNC machining is an important link to promote the sustainable development of the manufacturing industry. Due to the rapid development of the manufacturing industry, technical applications such as ultra-precision CNC machining and ultra-high-speed cutting have continued to appear, but for the entire machining industry, the development of equipment flexible manufacturing systems and computer integrated systems are relatively not suitable for large areas. Application. Now that CNC machining is mature and has higher technical requirements, 5-axis CNC machining has become the first choice for precision CNC machining.

Features of 5-axis CNC machining

1. Processing: Milling, chamfering, drilling and other processes can be completed after one-time clamping.

2. Precision: 5-axis CNC machining center adopts imported high-quality AC servo motors, ball screws, linear slides and electrical accessories to ensure that the equipment has high CNC machining accuracy.

3. Equipment: using imported spindle, speed control and peak performance under heavy cutting load.

4. In terms of tools: Disc-type tool magazines are used to greatly improve the efficiency of automatic tool change.

5. System: 5-axis CNC machining center adopts automatic positioning and clamping system.

6. In terms of safety: the use of protective devices can completely protect the personal safety of the operator.

7. In terms of processing materials: suitable for processing procedures such as industrial and aluminum alloy mounting holes, flow grooves, key holes, and shaped holes.

8. Tool protection: suitable for cooling spray system, which can cool the tool.

How to choose 5-axis CNC machining?

The 5-axis CNC machining center is more suitable for processing complex parts, many procedures, high precision requirements, multiple types of ordinary machine tools and numerous tools and fixtures, and parts that can be processed after multiple clampings. Since there are many types of industries, we can choose according to the complexity of the parts.

Complex surface parts

This type of 5-axis CNC machining parts generally appear in aviation, aerospace and machinery manufacturing. Because ordinary CNC machining cannot complete such parts, such as: spherical surfaces, blades on turbine engines, various curved molds, and marine propellers , Propellers, impellers, and some other freely combined curved surfaces and other CNC machining parts of underwater vehicles. Ordinary CNC machining cannot be completed, so it is most suitable to choose 5-axis CNC machining.

Box type parts

Box parts are mainly processed through multiple processes such as milling, drilling, expanding, boring, twisting, and tapping. The machining accuracy of this kind of CNC machined parts is generally required to be relatively high. For traditional machining, it is a relatively difficult thing, and the machining accuracy cannot be guaranteed, while the horizontal machining center is more suitable for machining, and 5-axis CNC machining can also be produced.

Alien parts

The so-called special-shaped parts refer to the processing of irregular parts, such as multi-directional processing parts of points, lines and surfaces. The rigidity of the shape type parts is relatively poor, so it is difficult or even impossible to process with ordinary CNC machine tools. It is difficult to control the clamping pressure during the processing and the processing accuracy is difficult to guarantee. However, 5-axis CNC machining is possible, because it can complete multiple processes or all processes because of the omnidirectional mixed processing characteristics of points, lines and surfaces.

Summarize

The 5-axis CNC machining center can efficiently realize the machining accuracy and quality of free-form surfaces. Because the angle of the cutter can be adjusted freely, it can avoid that the three-axis angle cannot be adjusted freely. Ensure the surface finish of 5-axis CNC machined parts, so as to obtain higher cutting efficiency and processing quality.