CNC turning is a way of using tools to work with lathes, and tools are an important part of CNC turning. The cutting part of the turning tool is composed of the main cutting edge, the secondary cutting edge, the rake face, the main flank face and the secondary flank face, and the nose angle. Since there are many types of lathe tools, a certain amount of tool knowledge is required. This article mainly talks about the tool knowledge of lathes, which allows you to understand the use of different CNC turning tools.

What is a CNC lathe tool?

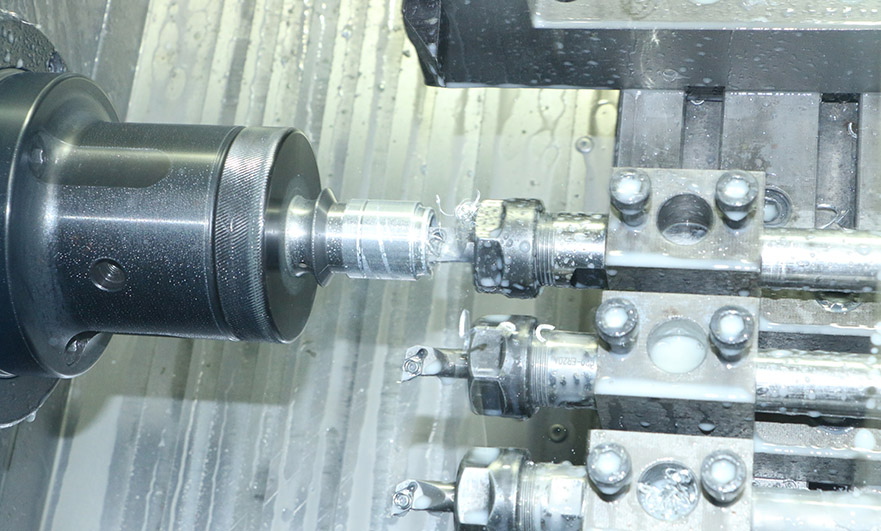

The turning tool is a tool with a cutting part used for CNC turning. Turning tools are one of the most widely used tools in CNC milling. The working part of the turning tool is the part that generates and handles chips, including the cutting edge, the structure for breaking or rolling up the chips, the space for chip removal or storage, and the passage of cutting fluid.

Classification and use of CNC turning tools

According to the classification of CNC turning tools, it can be divided into turning tools, knurling tools, thread cutting tools, and chamfering tools.

1. The turning tools are mainly divided into rough turning tools and fine turning tools

Rough turning tool: The main function of the rough turning tool is to remove excess metal in the shortest time allowed by the tool, workpiece and machine. They have a ground cutting angle that allows disassembly and can withstand the maximum cutting pressure.

Fine turning tool: Fine turning tool is a lathe tool used to remove CNC turning parts. The angle of the tool is polished to make the surface very smooth and precise.

Knurling tool

The knurling tool is a lathe tool that can produce knurled CNC turned parts by creating a specific pattern in a circular section. Therefore, you can use them as handles for fasteners such as handles or nuts.

Thread cutting tools

Thread cutting tools are suitable for cutting threads on CNC turning parts. Thread cutting is used for metric, BSW or American “V” threads formed by a single point. Its cutting edge is sharp, suitable for the shape and size of the cut line. It can be divided into internal thread cutting and external thread cutting.

Chamfering tool

Chamfering tools are lathe tools used to form grooves on CNC turning parts. If a lot of chamfering work is required, use a special chamfering tool to grind the side cutting edge angle to the chamfering angle. It can also be used to create smooth or dangerous edges on CNC turned parts.

How to Choose CNC Turning Tools?

1. Material type

When choosing the type of turning material, it is important to note that characteristics such as hardness, wear resistance, toughness, and stiffness play an important role in the types of turning tools you can use.

2. The need for shape

Each type of lathe tool will result in a different shape, because the shapes of CNC turning parts are various and have a certain complexity, then you must select the specified tool for the shape that needs to be processed.

The shape of the tool

The position of the cutting edge determines the cutting direction of the tool (right-hand tool, left-hand tool and round-end tool). Therefore, the shape of the turning tool is another factor to consider when choosing.

Summarize

In all CNC machining processes, lathe tools are an important part of machining operations. Both CNC cutting and CNC milling require the assistance of tools, so it is inevitable that there are many choices of CNC turning tools. This article introduces the different options for CNC milling and turning tools. Hope this article can help you understand the choice of CNC milling and turning tools.