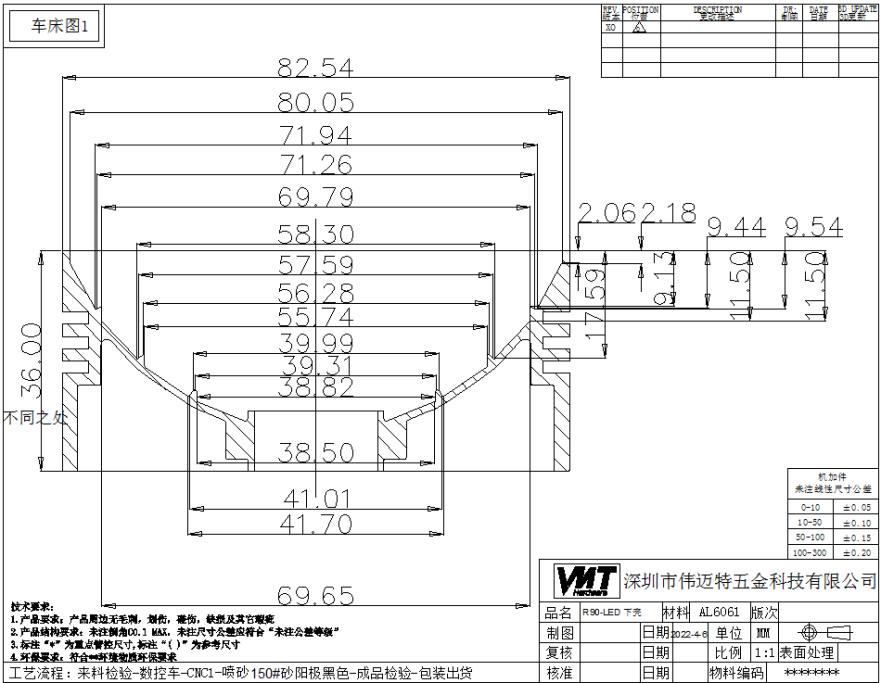

Example: Standard CNC Machining Part Drawing File

Preparing a CNC Machining Quote:

To provide an accurate CNC machining quote, you’ll need to gather several key pieces of information. Here’s what you should prepare:

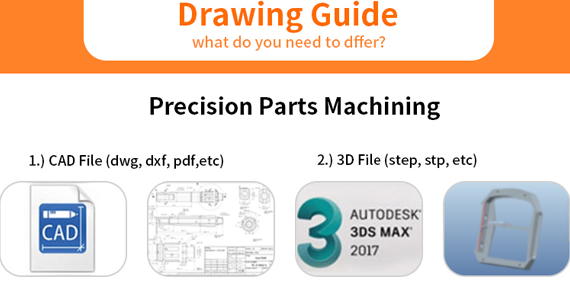

CAD Files: Obtain the Computer-Aided Design (CAD) files for the part you want to be machined. These files should be in a compatible format like STEP, IGES, or DXF. CAD files provide precise geometry and dimensions.

Material Specifications: Specify the material you want to use for the part. Provide details such as material type (e.g., aluminum, steel, plastic), grade or alloy (if applicable), and any special requirements (e.g., heat-treated, anodized).

Quantity: Determine the quantity of parts you need. CNC machining quotes often vary based on volume, so knowing the quantity is crucial.

Tolerances: Define the required tolerances for the machined part. Tolerances specify allowable deviations from the intended dimensions and are essential for precision machining.

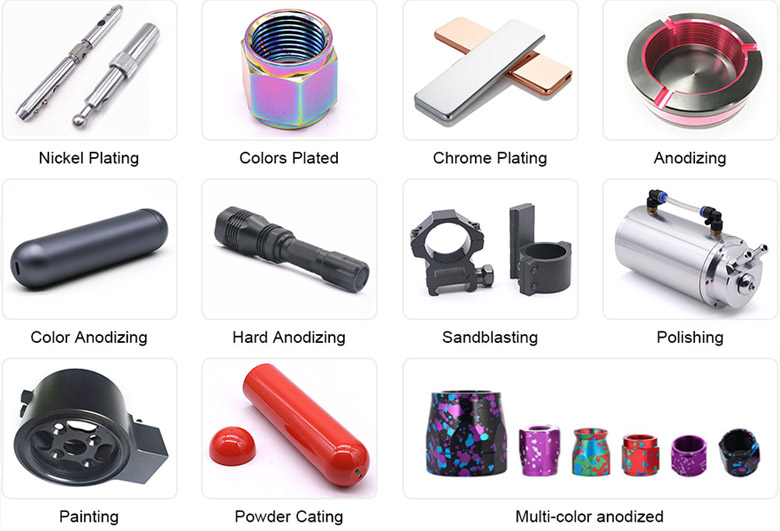

Surface Finish: Specify the desired surface finish for the part. This could be a particular Ra (roughness average) value or a specific surface treatment like polishing or anodizing.

Lead Time: Communicate your timeline or deadline for when you need the parts. This information can affect pricing, as rush orders may cost more.

Additional Processes: If any secondary processes are needed (e.g., assembly, welding, coating), provide details about these requirements.

Quality Standards: Specify any quality standards or certifications that must be met, especially if the parts are for a regulated industry like aerospace or medical.

Packaging and Shipping: Indicate how you want the finished parts to be packaged and shipped. Different shipping options can impact the quote.

Design Assistance: If you need design assistance or modifications to your CAD files, discuss this with the machining service provider. They may offer design services at an additional cost.

Budget Constraints: If you have a budget in mind, share it with the CNC machining service provider. This can help them tailor the quote to meet your financial constraints.

Any Special Requirements: If there are unique or specific requirements for your project, make sure to communicate them clearly. This could include aesthetic preferences, unique part features, or specialized tooling.

Once you’ve gathered this information, you can submit it to CNC machining service providers for quotes. It’s essential to provide detailed and accurate information to ensure that the quotes you receive align with your project’s needs and expectations.

Looking for a reliable cooperative CNC machining factory

Are you looking for the right CNC machining manufacturer? Why not give CNCMF CNC machining factory a try and let us help you.

We provide customized CNC machining and surface treatment services for copper, stainless steel, aluminum, titanium and other metal materials. Focusing on precision CNC machining and production for 13 years, whether it is prototype CNC machining or small batch CNC machining parts production, our team of professional engineers can choose the appropriate CNC machining process and surface treatment for you, reduce your production costs, and meet high standards Satisfy your needs. Choose, just upload your CAD files to our email: [email protected] to get a project quote.