When the customer’s needs are delivered, the two-dimensional and three-dimensional drawings related to the parts are generally provided in the form of drawings. It is not enough to provide drawings. The drawings often reflect the following parameters: technical parameters, materials, quantities, tolerances, post-machining and other requirements, Not all drawings can provide all the demand information, so the CNC machining factory has to communicate with the customer again. If some processes cannot be achieved, we need to communicate several times. After we understand all the needs of the customer, we can timely, accurate quote.

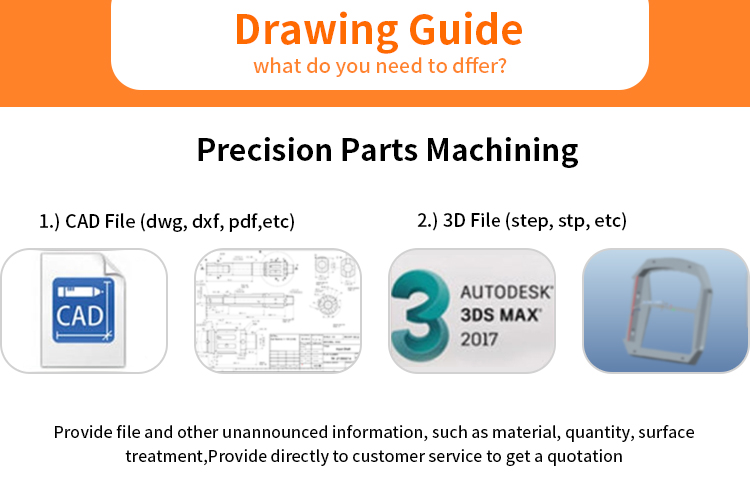

Precision CNC parts machining drawing format:

2D drawing file format: PDF or DWG (reflecting technical parameters, material, quantity, tolerance, post-machining and other requirements)

3D file format: STEP or IGS (convenient and more intuitive to see the structure, size, etc. of the product, for programming).

When the CNC machining factory performs precision data machining, it not only meets the customer’s technical requirements for parts machining, but also has the required performance. At the same time, it should pay attention to the improvement of production efficiency and worker work efficiency, so as to bring more economical and long-term effective to customers. Serve. Then let CNCMF explain to you the general CNC machining operation process of high-precision CNC parts machining factory!

First of all, after receiving the CNC machining requirements of the customer’s drawings, before starting the precision CNC machining, it is necessary to select a suitable CNC machine tool and write several sets of CNC machining procedures that are economical and efficient.

Then formulate an appropriate precision CNC parts machining plan, analyze the drawings of the parts to be processed, analyze the machining content of the CNC parts, and adopt appropriate CNC machining technology.

Secondly, the choice of material hardness. For some occasions, the higher the hardness of the material, the better, but it is limited to the hardness requirements of CNC machined parts. The material is moderately soft and hard, at least one grade lower than the hardness of the machine parts. One is that you must pay attention to the density of the material before CNC machining.

The most important thing in the machining of high-precision CNC parts is the design of the process flow, because the program steps of CNC parts machining, the selection of benchmarks, the selection of CNC machining tools, the selection and installation of fixtures, and the determination of CNC machining strategies and process parameters , which affects the quality of the product.

In the process of high-precision CNC parts machining, we should also pay attention to the full inspection of product quality. The CNCMF CNC machining factory is equipped with a complete range of precision CNC machining equipment, CNC machine tools, and testing equipment. It has 13 years of precision CNC machining experience and strict control of product quality. , can provide one-stop CNC machining services that save worry and effort.