What is deep hole CNC machining?

In the precision machining parts, deep hole CNC machining is a special machining method for CNC machining deep holes. It is suitable for the situation that needs to be processed inside the workpiece, such as drilling, reshaping, slamming, etc. So, what exactly is deep hole machining?

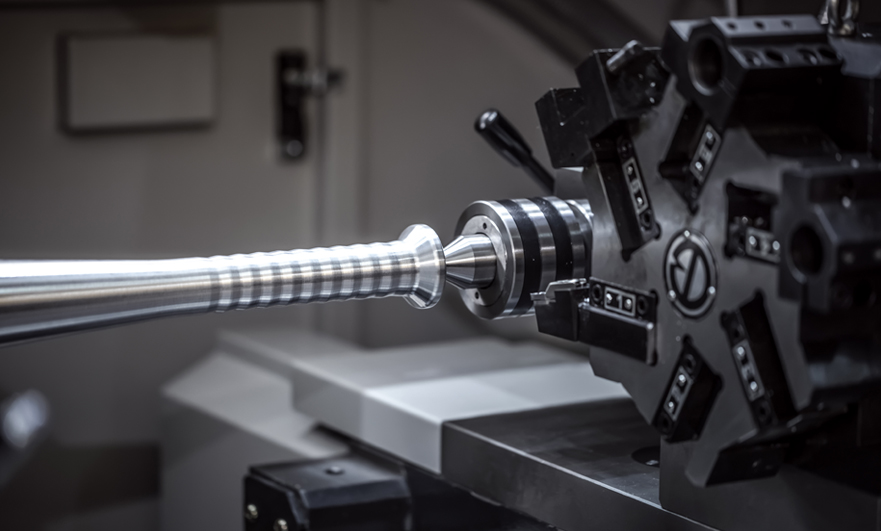

Deep hole machining refers to a machining process carried out inside the workpiece, and its characteristic is that the machining depth is much larger than its diameter. Deep hole machining usually uses long hole cutters or deep hole drills to gradually machine the hole to the required depth through a series of feeding and rotating actions. The difficulty of deep hole CNC machining lies in how to ensure the quality and CNC machining efficiency of the hole.

Deep hole machining is the creation of holes beyond the capabilities of conventional drilling. While traditional drilling methods are limited by the aspect ratio (the ratio of depth to diameter) of the hole, deep hole machining breaks these limitations. This technology is widely used in aerospace, automotive, medical device, oil and gas and other industries.

Cross-industry application

Aerospace: Aircraft components require unparalleled precision. Deep hole machining enables critical components such as engine components, landing gear and structural elements to be drilled.

Automotive: Automotive manufacturing relies on deep hole machining to produce engine components, transmission components and axles with tight tolerances.

Medical Devices: Surgical tools, implants and other medical devices require complex holes with extremely high precision to ensure patient safety.

Oil and Gas: Drilling equipment, tubing and well components are subjected to high pressure and stress. Deep hole machining ensures reliable performance.

Technology and Equipment

Deep hole machining involves advanced machinery and special tools:

Gun drilling: Drills a hole using a long, straight tool with a hole in the center, while pumping coolant through the tool to evacuate chips and control heat.

BTA Drilling: Boring and Trepanning Association (BTA) tools use tubes to transport coolant and remove chips. It is ideal for larger holes and higher material removal rates.

Jet Drilling: Utilizes a combination of internal and external coolant to effectively remove chips.

Advantages of Deep Hole Machining

Precision: high precision and straightness even in long holes.

Surface Finish: Produces an excellent surface finish, reducing the need for additional finishing operations.

Versatility: Works with a variety of materials including metals, plastics and composites.

Efficiency: Efficient chip evacuation and coolant delivery extend tool life and prevent overheating.

Complex Geometries: Ability to drill complex geometries not possible using traditional methods.

Deep hole CNC machining has the following characteristics:

1. Deep hole CNC machining has higher requirements on cutting fluid. Due to the high heat generated during the machining process, the cooling and lubricating functions of the cutting fluid are very important, which can reduce the wear of the tool and the thermal deformation of the workpiece surface.

2. Deep hole CNC machining needs to consider the cutting force. Since the tool is subject to a large cutting force during the cutting process, it is necessary to select the appropriate tool material and cutting parameters to ensure the tool life and CNC machining efficiency.

3. In deep hole machining, cutting vibration and cutting stability need to be considered. Due to the large CNC machining depth, it is easy to generate vibration during the cutting process, which affects the CNC machining quality. Therefore, it is necessary to take appropriate damping measures, such as using damping materials and optimizing the tool structure.

4. Deep hole CNC machining also needs to consider the problem of post-CNC machining treatment. Due to the large CNC machining depth, it is easy to generate waste materials such as cutting chips and cutting oil, which need to be cleaned and treated in time to ensure the cleanliness of the CNC machining environment and the surface quality of the workpiece.

In the CNC machining of precision parts, deep hole CNC machining is a special CNC machining method for deep hole CNC machining requirements. It needs to consider many aspects such as cutting fluid, cutting force, cutting vibration, and post-CNC machining treatment. Through scientific and reasonable process and equipment selection, the deep hole CNC machining task can be effectively completed, and the CNC machining quality and efficiency can be improved.

Conclusion

Deep hole machining is a key technology that plays a key role in producing parts that require impeccable precision and performance. Industries of all kinds rely on this method to manufacture holes to tight tolerances and quality standards. With specialized equipment, technology and a range of advantages, deep hole machining enables the manufacture of complex and reliable components that continue to shape fields.