Due to the continuous fermentation of the epidemic, the global supply demand for precision machining medical equipment products such as ventilators and forehead thermometers is second only to masks and become “urgently needed products.”

Affected by the severe situation of the global new crown pneumonia epidemic, my country’s medical device demand is growing rapidly. As a manufacturer of OEM and ODM precision machining metal parts, my country’s medical device industry has ushered in the development opportunity for export, but my country’s medical device products are still in the middle The low-end, coupled with the different testing standards of medical equipment quality management systems in various countries, has brought certain resistance to the export of my country’s medical equipment products. To change the international prejudice on customized processing of medical device accessories, it is necessary to accelerate the pace of transformation and upgrading of the medical device industry, so as to promote the precision of customized processing of medical device hardware parts.

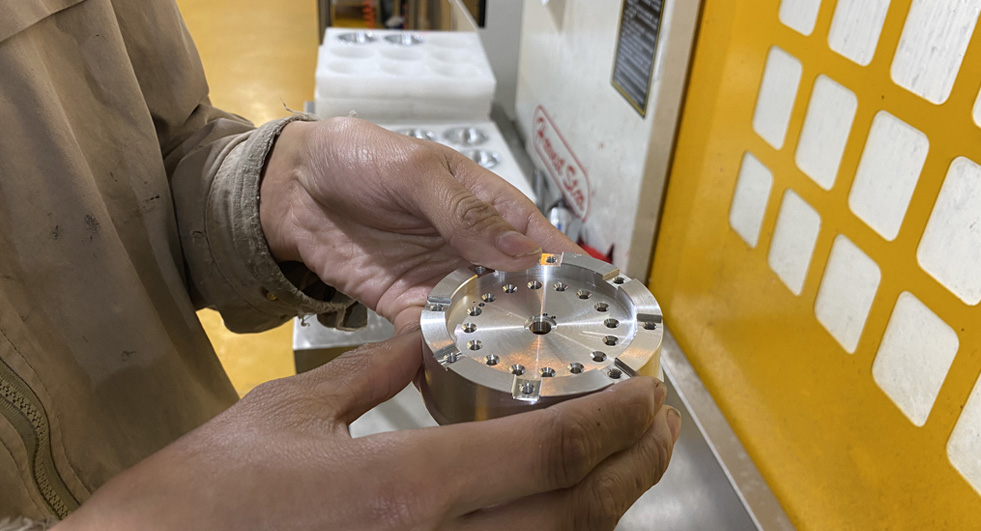

Want to know how CNCMF precision machining factory produce high-quality and zero-error precision medical equipment hardware parts?

1. Improve the level of cutting

In precision machining factory, when the workpiece is being cut, thesurface of the workpiece will form almost the same impression as the tool shape and leave a lot of scales, which is easy to increase the roughness of the workpiece surface and reduce the quality of the surface of the workpiece; in general, In this case, during cutting, the tip arc radius of the tool should be appropriately increased, and the tool feed should be appropriately reduced to reduce the height of the residual area of the tool on the workpiece as much as possible to ensure that the surface roughness of the workpiece is controlled at Within a proper range, this can effectively reduce the built-up edge and scale on the surface of the workpiece, thereby improving the quality of the surface of the workpiece and prolonging the service life of the workpiece.

2. Improve cutting speed

When the workpiece is cutting, if the cutting speed is high, the plastic deformation of the surface of the workpiece during the cutting process can be greatly reduced. The higher the cutting speed, the smaller the degree of plastic deformation, which can effectively reduce the surface roughness of the workpiece. If the cutting speed is not enough, the workpiece will have built- up edge during the cutting process, which will affect the surface quality of the workpiece.

3. Improve the accuracy of precision machining factory equipment

The precision machining of the workpiece is mainly completed by the machine tool. The error of the machine tool itself will directly affect the accuracy of the workpiece. This requires the high accuracy of the machine tool itself to effectively reduce the error generated during the machining process. The error of the tool and the fixture will also affect the accuracy of the workpiece, and corresponding measures can be taken to reduce the wear of the tool. In this way, the accuracy of the processed workpiece can be improved and the quality of the processed workpiece can be improved.

The quality of the workpiece is the key to the development of the enterprise. Therefore, improving the quality of the precision machining workpieces and improving the quality of the workpieces is an urgent matter for every precision machining factory.