The Stainless Steel CNC Machining Process Unveiled

CNC machining of stainless steel involves a systematic and precise process to transform raw materials into intricate and accurate components. Here is a detailed overview of the typical process flow for machining stainless steel using CNC techniques:

Material Selection:

Choose Stainless Steel Grade: Depending on the specific application and requirements, select the appropriate grade of stainless steel, such as 304, 316, or others.

Design and Programming:

CAD Design: Create a detailed Computer-Aided Design (CAD) model of the desired part, ensuring accuracy and precision.

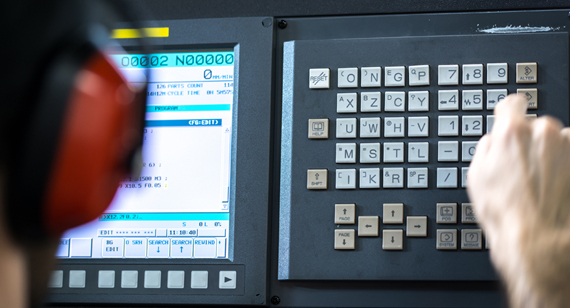

CAM Programming: Translate the CAD design into a CNC-compatible program using Computer-Aided Manufacturing (CAM) software. This step involves defining toolpaths, machining strategies, and cutting parameters.

Material Preparation:

Raw Material Inspection: Verify the quality and specifications of the chosen stainless steel stock.

Stock Cutting: Cut the raw material into suitable blanks or billets, ensuring they match the dimensions required for the CNC machining process.

Fixturing and Workholding:

Fixture Design: Develop fixtures or clamping mechanisms to secure the stainless steel workpiece in place during machining.

Workpiece Alignment: Ensure precise alignment of the workpiece within the CNC machine to prevent errors and achieve accurate cuts.

Tool Selection:

Choose Cutting Tools: Select appropriate cutting tools based on the stainless steel grade and the intricacy of the design. Carbide or high-speed steel tools are commonly used for stainless steel machining.

CNC Machining Operations:

Rough Machining: Remove excess material using roughing passes, optimizing cutting speeds and feeds for efficient material removal.

Semi-Finishing: Perform semi-finishing operations to bring the part closer to its final dimensions while maintaining a good surface finish.

Finishing Passes: Execute finishing passes with fine-tuned cutting parameters to achieve the desired surface quality and dimensional accuracy.

Quality Control:

In-Process Inspection: Regularly inspect the CNC machined part during the process to detect any deviations from specifications.

Final Inspection: Perform a comprehensive inspection of the finished part, checking dimensions, surface finish, and overall quality.

Surface Treatment (Optional):

Deburring: Remove any sharp edges or burrs resulting from the machining process.

Surface Finishing: Apply additional surface treatments, such as polishing or passivation, to enhance the aesthetics and corrosion resistance of the final product.

Packaging and Shipping:

Secure Packaging: Package the CNC machined stainless steel components securely to prevent damage during transportation.

Shipping: Arrange for the timely and secure shipping of the finished parts to the designated destination.

By following this comprehensive process flow, CNC machining ensures the precision, accuracy, and quality of stainless steel components, making it a crucial method for producing intricate parts in various industries.