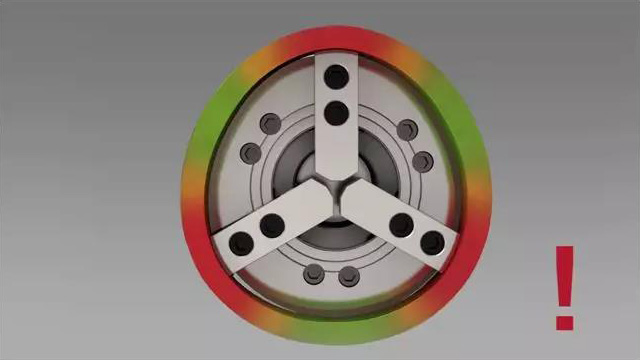

When machining thin-walled or ring-shaped workpieces,Overcoming the deformation of the workpiece is the first problem to face,Choosing the right type of soft jaw and proper chuck pressure is the key.

Under the same chuck pressure, the sector-shaped soft jaws have a larger contact area than the standard soft jaws, which means that the pressure on the workpiece is more uniform, while the standard soft jaws will have the following conditions:

The actual situation may not be as obvious as in the picture, but in the video at the bottom, you will clearly see that under the same conditions except for the different types of soft jaws, the degree of deformation of the workpiece has even appeared dozens of times. The difference.

Regardless of whether it is a fan-shaped soft claw or a standard soft claw, it will need to be re-repaired due to excessive wear of the soft claw or the replacement of the processed parts. It is to increase the number of times the soft claw is used, and more detailed markings will reduce the possibility of misuse.

Next is the choice of the claw trimmer:

Generally speaking, the claw cutter on the left is for the inner claw, and the claw on the right is for the outer claw.

The following problems should be paid attention to when making or re-repairing soft jaws:

The T-block cannot exceed the maximum diameter of the chuck

The chuck pressure when trimming the jaw is close to the pressure when processing the workpiece

The chuck is in the middle of the range of motion

The direction of the clamping force when trimming the jaws is the same as the direction of the workpiece clamping force

Pay attention to the speed when trimming the jaws

Add undercut

Remove burrs and sharp corners