With the rapid development of manufacturing industry, CNC machining technology is increasingly used in the field of machinery manufacturing. As the core product of CNC machining, the quality and stability of CNC precision machining parts are directly related to the performance and life of the product. Therefore, a set of CNC precision parts needs to undergo rigorous verification and testing before mass production to ensure its stability and reliability. This article will introduce in detail the stable mass production verification process of a set of CNC precision parts.

1. Overview of CNC machining technology

CNC machining is a machining method based on computer numerical control technology. It controls the movement and machining process of the machine tool through computer programs to achieve high-precision and high-efficiency machining. CNC precision parts refer to parts with high precision, high complexity and high added value manufactured through CNC machining technology. These parts are widely used in aviation, aerospace, automobiles, electronics and other fields, and have extremely high requirements on product quality and stability.

2. Stable mass production verification process of CNC precision parts

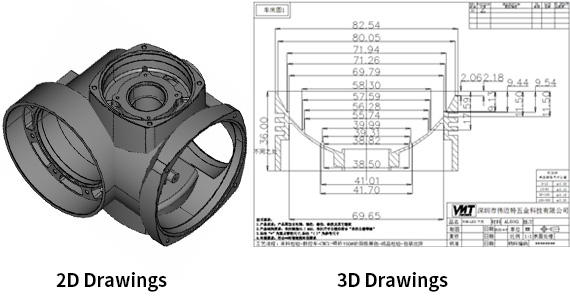

Drawing review and design verification

First, the drawings of multiple CNC precision parts need to be rigorously reviewed. Drawings are the basis for parts manufacturing and their accuracy, completeness and operability must be ensured. The review includes the structure, dimensions, tolerances, materials, etc. of the parts to ensure that they meet the design requirements and relevant standards. At the same time, design verification is required to ensure coordination and compatibility between multiple CNC precision parts.

Material preparation and inspection

For many CNC precision parts, material selection is crucial. High-quality materials that meet design requirements must be selected and quality inspected to ensure they meet relevant standards. At the same time, materials need to be tested for stability to ensure they remain stable during long-term use.

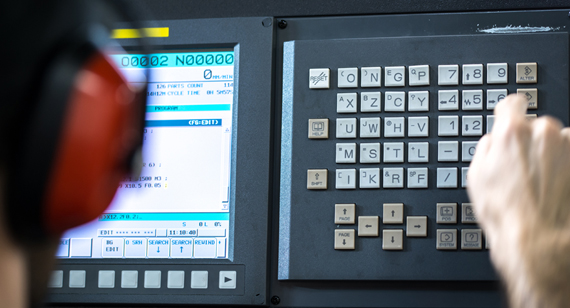

CNC programming

CNC programming is a key link in CNC precision parts manufacturing. According to the drawing requirements, precise CNC programming of the parts is required to ensure that the machine tool can process according to the preset paths and parameters. During the programming process, care must be taken to avoid errors such as collisions and overcuts to ensure the smooth progress of the machining process.

CNC machining process monitoring

During the machining of CNC precision parts, real-time monitoring of the machining process is required. Monitoring content includes machine tool status, tool wear, cutting parameters, etc. to ensure the stability and reliability of the machining process. At the same time, abnormal situations during machining need to be handled in a timely manner to avoid affecting product quality.

Quality inspection

Quality inspection is an important part of ensuring the stability of CNC precision parts. After machining is completed, a comprehensive quality inspection of the parts is required, including size, shape, surface quality, etc. High-precision measuring equipment and professional inspection personnel are required during the inspection process to ensure the accuracy and reliability of the inspection results. Unqualified parts need to be reworked or scrapped in a timely manner to avoid affecting the quality stability of mass production.

Reliability test

In order to ensure the stability of CNC precision parts during long-term use, reliability testing is required. Reliability testing includes durability testing, environmental adaptability testing, etc. to simulate various conditions and environmental factors during actual use of parts. Through reliability testing, potential problems and hidden dangers can be discovered and solved, and the reliability and stability of the product can be improved.

Verification before mass production

Before mass production, the entire production process needs to be verified and confirmed. This includes a comprehensive inspection of the quality control of raw materials, the accuracy of CNC programming, the stability of the machining process, the reliability of quality inspections, etc. Only when all links meet the requirements can mass production begin.

3. Summary

The verification process for stable mass production of a set of CNC precision parts is a complex and rigorous process. It involves drawing review, material preparation, CNC programming, machining process monitoring, quality inspection and other links. Only through rigorous verification and testing can the stability and reliability of CNC precision parts be ensured. Looking to the future, with the continuous development of science and technology, the manufacturing technology of CNC precision parts will become more advanced and mature. At the same time, the verification process for stable mass production of CNC precision parts will also be more stringent and precise. We believe that in the future development, CNC precision parts will make greater contributions to the development of manufacturing industry.