Which one is more suitable for CNC machining or 3D printing? Next, CNCMFCNC machining manufacturer will popularize this knowledge for everyone. Which method is better for CNC prototype machining parts proofing? 3D printing or CNC machining.

Let’s first look at their similarities:

Both processes can meet the needs of early design engineers with initial prototypes of appearance, function or structure without the delays caused by tooling, or molding.

Both CNC machining processes can produce parts from a variety of materials.

Both of these CNC machining techniques enable the production of prototypes or low-volume CNC machined parts required for product development at a reasonable cost.

Next, let’s take a look at the characteristics of 3D printing:

Advantages of 3D printing

It reduces the technical requirements in the production process and reduces the difficulty of making internal complex structural parts. That is to say, the skills and workload of programming and manual post-processing for 3D printed products are greatly reduced.

Printing can generate objects of any shape directly from computer graphics data without CNC machining or molds, thereby greatly shortening the production cycle of products and increasing productivity.

Compared with the traditional CNC prototype manufacturing industry, the advantages of 3D printing technology are mainly reflected in the following points:

Manufacturing complex parts costs little difference. It uses additive manufacturing, so the difficulty of the part will not increase the cost too much, and its cost mainly depends on the weight of the part itself.

Reduce the time of disassembly and splicing. All parts that can be completed within the stroke are integrally formed.

The delivery time is highly controllable. Because unnecessary processes are reduced in the middle, some accidents and quality factors in the production process are avoided.

With the development of 3D printing technology, raw materials have also changed from the original simplification to diversification, and some customized equipment and materials also have some unique properties or functions. It occupies an indispensable position in some fields.

Disadvantages of 3D printing

Most of the strength and hardness of the material are not as good as that of the traditional sheet, and the materials that can be used for structure and function are relatively simple.

Transparent or translucent materials tend to change color over time.

For some materials with characteristic requirements (such as corrosion resistance or flame retardant), it cannot be processed.

It is easy to deform, and most of the products in small batches will be made of 3D printed parts as prototypes and then made by the process of complex molding.

Due to the limitation of equipment travel, relatively large parts such as medical equipment and automobiles are not suitable for 3D printing.

Advantages of CNC machining

With the rapid rise of 3D printing technology, the advantages of traditional CNC machining methods are becoming less and less obvious, but at this stage it still dominates the CNC prototype machining industry for the following reasons:

Industrially designed CNC machining parts can be processed by CNC regardless of appearance, structure and function requirements.

Materials have a wide range of properties. For functional parts with characteristic requirements, corresponding or similar materials can be found in the market to meet production needs.

It is suitable for processing some large CNC machining parts. From the perspective of cost, the cost is much lower than that of 3D printing. Now, due to the mature use of materials and adhesives, disassembly will not affect the strength after splicing.

If the equipment is CNC machined or needs manual post-processing, various surface treatments can be directly applied to the surface of the CNC machined parts after completion, and the effect is close to or even higher than the product itself.

Disadvantages of CNC machining

For small and complex parts CNC machining is difficult and time-consuming, and it is difficult to process the details in place.

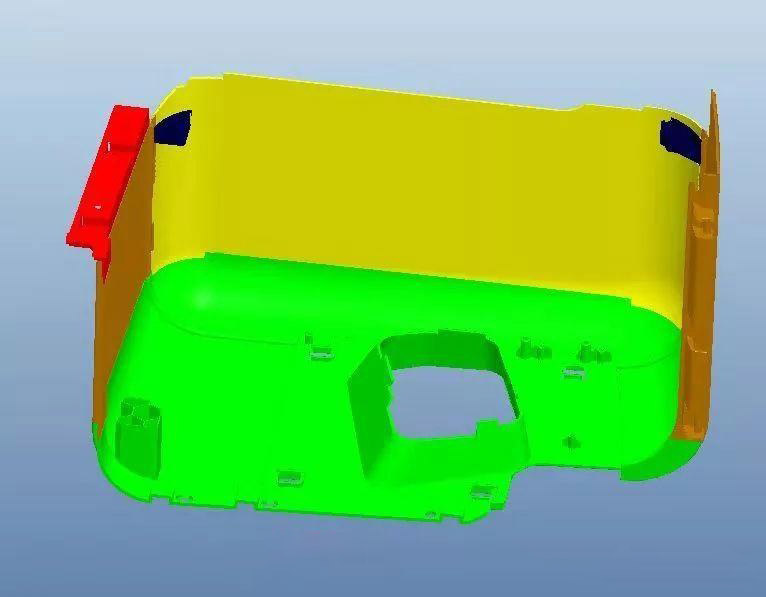

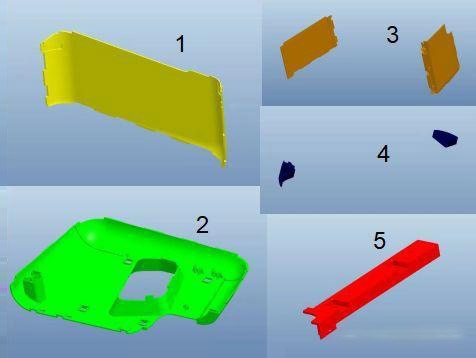

There are many process flows. Compared with 3D printing, the drawings need to be disassembled, programmed, machined CNC machined, and the CNC machined parts need to be manually cleaned, deburred, and spliced after processing. (The following picture is the CNC above. Disassembly of machined parts)

The CNC machining cycle is long and the manual processing workload is large, which ultimately affects the slow flow of orders.

Based on the above comparison, it can be seen that CNC machining is more suitable for processing various large CNC machining parts with simple structure and relatively heavy weight, while 3D printing is mainly suitable for making various complex structures and thin-walled parts with appearance.

No matter what kind of CNC machining method is used, customers should consider what kind of CNC machining plan to adopt according to their actual needs (workpiece size, complexity, cost budget, development cycle, and other factors), but the current CNC prototype Basically, the processing factory will evaluate the order received and make a reasonable CNC machining method between time and cost. In short, these two CNC machining methods are complementary in the current CNC prototyping machining industry, and there is no difference between good and bad.

The above is what CNCMFCNC prototype machining factory introduced to you about CNC prototype machining and proofing. Which method is better? 3D printing is still the analysis of CNC machining, I hope to provide you with a reference.

CNCMF focuses on one-stop CNC prototype machining services. There are 100+ CNC machining machines, providing more than 40 kinds of materials, CNC prototype machining services with a precision of 0.05mm, and CNC machining services such as CNC machining of precision aluminum casings. Provides free service design, project review and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!