For a CNC machining manufacturer, simple processing is the easiest and fastest way to recover costs, because it can be delivered in a short time, the payment turnover is fast, and the products are relatively simple.

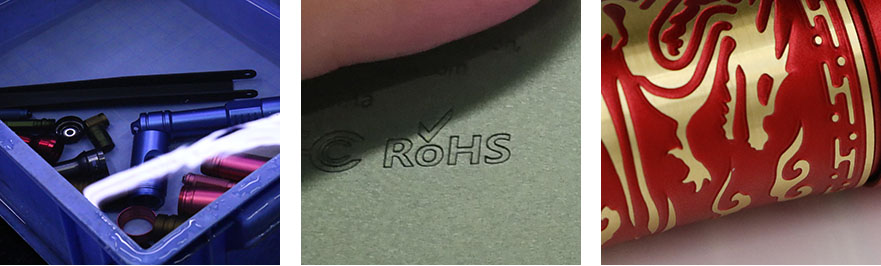

Jack Ma said that it is not a skill to make 10,000 pieces, but It is the ability to make 1 piece and deliver it to the customer in time. This sentence has aroused many people’s deep thinking. More than 90% of CNC machining factories prefer parts with large batches without surface treatment,then can be delivered after processing, there are too many factories like this. So now there is price competition between manufacturers, but the factories that can work with CNC machining as well and also provide customers with rich surface treatment, frankly speaking, it is a challenge for a factory. Especially for parts that require a variety of surface treatment processes. For example, for aluminum parts, some of them require oxidization, and some of them require second oxidization after polishing, also engraving or etching and then make oxidation. In these processes, each step will affect the yield of parts, especially now that many surface treatment manufacturers are not professional or careless. Once the batch is defective, the CNC may increase the cost, which means that this batch is done in vain.

Therefore, in this process, a hanging point on the product or a method of hanging the tool are very important. For a CNC machining factory, if they don’t have a team to work with that, it is impossible to control these things with the strength of one or two people, and the final result will The result will be that both parties are dissatisfied, or the delivery time will not be reached, or give up directly, so a machining factory that can really do a good job in surface treatment is a manifestation of its comprehensive strength, which is one of the direct reasons why many CNC machining manufacturers are unwilling to make surface treatment.Hope the above can help you choose the right CNC machining manufacturer! Thanks.