The Significance of Precision in CNC Machining for Part Manufacturing

Precision in CNC machining holds paramount importance for several key reasons:

Quality Assurance:

Meeting Specifications: Precision ensures that the manufactured parts adhere to the exact specifications and tolerances required. This quality control is critical for components used in various industries, including aerospace, automotive, and medical.

Functional Accuracy:

Optimal Performance: Parts with precise dimensions and accurate geometries function as intended. In applications like automotive engineering or medical devices, where safety and performance are non-negotiable, the accuracy of each component is crucial.

Interchangeability:

Consistency in Production: Precise CNC machining guarantees that each part is interchangeable with others of the same specifications. This interchangeability is vital for large-scale production and assembly processes.

Reduced Waste:

Material Efficiency: CNC machining with high precision minimizes material waste. The exact removal of material as per design reduces scrap, making the manufacturing process more sustainable and cost-effective.

Enhanced Durability:

Longevity of Components: Precisely machined parts are less prone to premature wear and tear. This is especially important in industries such as aerospace and defense, where components must withstand harsh conditions over extended periods.

Complex Geometry:

Accurate Replication: Precision is crucial when machining complex and intricate geometries. CNC machines excel at replicating intricate designs, ensuring that even the most complex parts are produced with accuracy.

Efficient Assembly:

Smooth Integration: Components with precise dimensions facilitate smooth assembly processes. This is particularly significant in industries where assembly line efficiency is a critical factor.

Compliance with Standards:

Meeting Industry Regulations: Many industries have stringent standards and regulations regarding the precision of machined parts. Compliance with these standards is essential for product safety and regulatory approval.

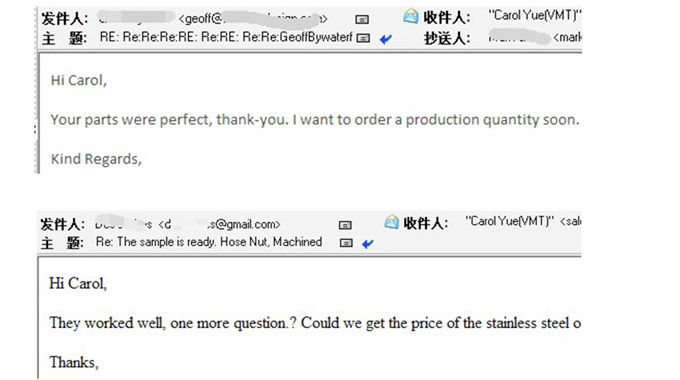

Customer Satisfaction:

Meeting Expectations: Precision is directly linked to the final product’s quality. Meeting or exceeding customer expectations in terms of accuracy enhances customer satisfaction and builds trust in the manufacturer’s capabilities.

In conclusion, precision in CNC machining is not merely a desirable attribute; it is a fundamental requirement. From ensuring the functionality and durability of components to minimizing waste and adhering to industry standards, precision is the cornerstone of successful CNC part manufacturing.