As we delve into the world of metals, we often encounter the captivating transformation of their surfaces over time. One curious question that arises is, “Does brass or bronze turn green?” This article aims to unravel the mystery behind the verdigris patina that sometimes graces these metals, exploring the science, reasons, and ways to manage this fascinating phenomenon.

Table of Contents

-

Introduction

-

Understanding Brass and Bronze

-

The Formation of Patina

-

Factors Influencing Patina Formation

-

Verdigris: The Green Patina

-

Does Brass Turn Green?

-

Does Bronze Turn Green?

-

Managing Patina

-

Preserving the Original Appearance

-

Utilizing the Patina Aesthetics

-

Preventing Patina Formation

-

Caring for Patinated Items

-

Embracing the Natural Evolution

-

Conclusion

-

Frequently Asked Questions

Introduction

Metals have an undeniable allure, whether in art, architecture, or everyday objects. Brass and bronze, two popular alloy choices, are known not only for their durability but also for their unique ability to develop a greenish layer over time. This article aims to shed light on why this happens, whether it’s the same for both metals, and how we can manage and appreciate this process.

Understanding Brass and Bronze

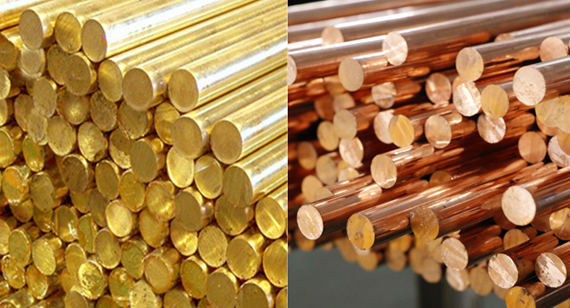

Before delving into the patina transformation, let’s understand brass and bronze. Brass, composed mainly of copper and zinc, is celebrated for its golden appearance and wide range of applications, from musical instruments to decorative items. Bronze, on the other hand, is primarily a mixture of copper and tin, known for its reddish-brown hue and historical significance.

The Formation of Patina

Patina is a thin layer that forms on the surface of metals due to chemical reactions. It’s a result of the metal’s interaction with elements in its environment, such as oxygen, moisture, and pollutants. While patina can manifest in various colors, the green patina, known as verdigris, is a common occurrence on both brass and bronze.

Factors Influencing Patina Formation

Several factors contribute to the formation of patina. Exposure to moisture, humidity, and airborne pollutants accelerates the process. Additionally, the composition of the alloy, local climate, and the object’s location also play a role. These factors collectively determine the rate and extent of patina development.

Verdigris: The Green Patina

Verdigris, often associated with aged copper roofs and historical artifacts, is particularly captivating due to its vibrant green color. It forms when the copper in brass or bronze reacts with atmospheric oxygen and carbon dioxide, leading to the creation of copper carbonate. This layer not only adds a unique aesthetic but also protects the underlying metal from further corrosion.

Does Brass Turn Green?

Yes, brass can indeed turn green due to the formation of verdigris. When brass items are exposed to the elements, the copper content reacts with the environment, resulting in the gradual emergence of the characteristic green patina. This transformation is often prized for the vintage and artistic feel it adds to objects.

Does Bronze Turn Green?

Similarly, bronze can also develop a green patina. The copper component in bronze reacts in much the same way as it does in brass. Over time, bronze sculptures, architectural elements, and other items can acquire a stunning greenish layer that enhances their visual appeal.

Managing Patina

While some appreciate the natural patina, others prefer to maintain the original appearance of brass and bronze. Several methods can be employed to manage patina. Regular cleaning and waxing create a barrier against environmental factors, slowing down the patina process. Alternatively, utilizing protective coatings can help preserve the metal’s initial shine.

Preserving the Original Appearance

If you’re keen on keeping your brass and bronze items looking shiny and new, preventative measures are key. Keep them away from moisture and pollutants, storing them in controlled environments when not in use. Regular cleaning with mild solutions and gentle polishing can help retain their original allure.

Utilizing the Patina Aesthetics

On the other hand, some individuals appreciate the allure of patinated surfaces. The unique color and texture can infuse a sense of history and character into various objects. Artists and designers often use the patina effect deliberately to create an antique or vintage aesthetic.

Preventing Patina Formation

If you wish to prevent patina altogether, consider storing your brass and bronze items in airtight containers or display cases. This minimizes their exposure to air and moisture, effectively slowing down the patina-forming reactions.

Caring for Patinated Items

For those who embrace the patina, caring for patinated items involves minimal effort. Gentle dusting and occasional cleaning with a soft cloth can maintain their appearance without disrupting the charming green layer that has developed.

Embracing the Natural Evolution

In the end, whether you choose to preserve the original shine or embrace the green transformation, both options have their merits. The evolution of brass and bronze over time is a testament to their unique properties and their interaction with the world around them.

Conclusion

The question, “Does brass or bronze turn green?” is met with a resounding yes. The formation of patina, particularly the verdigris patina, is a natural and intriguing phenomenon resulting from the interaction between these metals and their environment. Whether you choose to preserve the pristine shine or welcome the charming green layer, the journey of brass and bronze is a captivating one.

Frequently Asked Questions

Can I prevent brass from turning green?

Yes, by employing preventive measures such as regular cleaning, waxing, and protective coatings.

Is patina harmful to metals?

No, patina can actually protect the metal underneath from further corrosion.

Can I reverse patina formation?

Reversing patina is challenging and may alter the appearance of the object, so prevention is usually a better approach.

Why do some people prefer patina?

Patina adds a sense of history, character, and aesthetic value to objects, making them appear antique and unique.

Can I accelerate patina formation for artistic purposes?

Yes, artists often use various techniques to expedite patina formation for creative and aesthetic reasons.

Can I prevent patina formation on copper CNC machining parts?

While complete prevention is challenging, regular cleaning and protective measures can slow down the patina process.

Does patina affect the structural integrity of CNC machined copper parts?

No, patina generally acts as a protective layer, preserving the underlying metal and often enhancing its durability.

Can I remove patina from copper CNC machining parts?

Removing patina without altering the original appearance can be difficult. Prevention is usually more effective.

Is patina considered a defect in CNC machining parts?

Patina is not a defect; it’s a natural process that can enhance the visual appeal of copper parts.

Can I accelerate patina formation for artistic purposes?

Yes, artists often use controlled environments and chemical treatments to accelerate patina for creative effects.