Get quotes on custom parts with our Online CNC Routing Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

CNCMF stands out as a trusted and innovative industry provider of CNC routing services. With its expertise, state-of-the-art technology, and commitment to quality, CNCMF has become a go-to resource for businesses and individuals seeking top-notch CNC routing solutions for production components as well as for finished parts. We at CNC Machining Factory take pride in providing the best quality solutions to our customers, and that is why we are ISO 9001:2015, ISO 13485, AS9100D certified, and ITAR (International Traffic in Arms Regulations) registered.

Our CNC routing services cover a wide range of materials, including MDF (medium-density fiberboard), plywood, acrylic, polyurethane foam, and polyethylene sheet, as well as softer metals like brass, aluminum, and occasionally steel.

What Is CNC Routing?

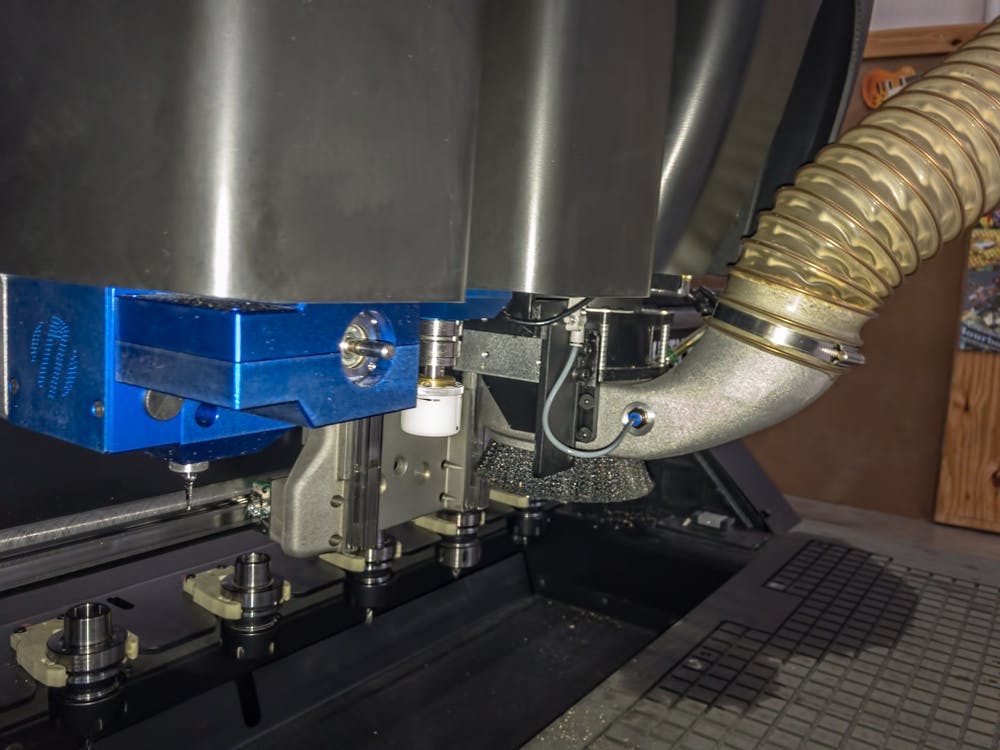

CNC (computerized numerical control) routing is a subtractive manufacturing process that utilizes computer-controlled machines to cut and shape various materials, typically wood, plastic, or metal. It involves the use of a rotating cutting tool, called a router, which is guided by precise digital instructions to create elaborate and precise cuts, holes, and contours in the material.

CNC routing is similar to other CNC processes, such as CNC milling and CNC turning, in that they all involve computer-controlled machines and follow a similar workflow. However, there are some notable differences as listed below:

- Cutting Tool: In CNC routing, a rotating router bit is used as the primary cutting tool, whereas CNC milling typically employs a rotating multi-point cutting tool called an end mill. CNC turning, on the other hand, uses a single-point cutting tool to shape cylindrical parts.

- Material Orientation: CNC routing machines are typically designed to work with flat or sheet materials, such as plywood or acrylic sheets, which are secured to a table. In contrast, CNC milling and turning processes often deal with block or cylindrical workpieces.

- Cutting Direction: CNC routing machines primarily operate in the X and Y axes, cutting along the plane of the material. CNC milling and turning machines, on the other hand, can move in multiple axes, allowing for more complex and three-dimensional machining.

- Applications: While there can be some overlap, CNC routing is often associated with applications that require large-scale cutting, such as furniture making, sign manufacturing, and cabinetry. CNC milling is commonly used for precise and intricate machining of parts, while CNC turning is ideal for producing cylindrical or rotational parts like shafts and fittings.

Despite these differences, all CNC processes share the advantages of precision, repeatability, and the ability to create complex shapes with minimal human intervention. They offer increased efficiency, reduced labor costs, and the ability to produce consistent and high-quality results.

Advantages of CNC Routing

CNC routing offers several advantages over traditional manual routing or other manufacturing methods, for example,, plasma or laser cutting. Here are some key advantages of CNC routing:

- Tight Tolerances

- Flexibility

- Reproducibility

- Complex Shapes and Intricate Designs

Tight Tolerances

CNC routing machines are capable of extremely precise cuts and shaping, allowing for intricate designs and tight tolerances. The computer-controlled nature of the process ensures consistent accuracy and eliminates the variations that can occur with manual routing.

Flexibility

CNC routing machines can work with a wide range of materials, including wood, plastic, foam, composites, and nonferrous metals. This versatility makes CNC routing suitable for a number of industries and applications, such as furniture manufacturing, signage, prototyping, cabinetry, and architectural millwork.

Reproducibility

With CNC routing, the same design can be reproduced accurately and consistently, ensuring uniformity across multiple parts or batches. This is especially valuable in industries where precision and consistency are crucial, such as aerospace, automotive, and electronics.

Complex Shapes and Intricate Designs

CNC routing enables the creation of complex shapes and intricate designs that would be difficult or time consuming to achieve manually. The computer-controlled machine can execute intricate cuts, curves, and patterns with ease, opening up new possibilities for creative and customized applications.

Common Materials for CNC Routing

CNC routers are compatible with a wide range of materials, including: soft metals, wood, plastics, and composites. Below is a list of some of the most common materials used in CNC routing:

- ABS (Acrylonitrile Butadiene Styrene)

- ACM Panel (Aluminum Composite Material)

- Baltic Birch Plywood

- HDPE (High-Density Polyethylene)

- MDF (Medium-Density Fiberboard)

- Polycarbonate

- Foam

- UHMW (Ultra-High Molecular Weight Polyethylene)

- Aluminum

- Brass

- Composites

- ABS (Acrylonitrile Butadiene Styrene): ABS is a thermoplastic polymer known for its toughness and impact resistance. It is commonly used in applications such as prototyping, automotive parts, enclosures, and consumer goods. ABS offers good strength and durability, is easy to machine, is available in various colors, and is cost-effective.

- ACM Panel (Aluminum Composite Material): ACM panel is a lightweight composite material consisting of a thin aluminum sheet bonded to a polyethylene or fire-retardant core. It finds applications in signage, architectural cladding, exhibition displays, and interior design. ACM Panel provides excellent flatness, a high strength-to-weight ratio, weather resistance, and ease of shaping and cutting, making it suitable for outdoor use.

- Baltic Birch Plywood: Baltic birch plywood is a type of plywood made from multiple layers of birch veneer. It is known for its strength and durability. It is commonly used in furniture, cabinetry, jigs, and decorative items. Baltic birch plywood offers stability, void-free construction, high strength, good screw-holding ability, and suitability for intricate cuts and engraving.

- HDPE (High-Density Polyethylene): HDPE is a versatile thermoplastic known for its high strength-to-weight ratio and resistance to chemicals. It finds applications in kitchen cutting boards, marine applications, wear strips, and storage containers. HDPE is lightweight, exhibits excellent chemical resistance, has low moisture absorption, is easy to machine, and is cost-effective.

- MDF (Medium-Density Fiberboard): MDF is a type of engineered wood product that is manufactured by breaking down residuals of hardwood or softwood into wood fibers. These fibers are then combined with resin and compressed to form a dense and uniform board. MDF finds widespread use in applications such as cabinetry, furniture, signage, and decorative panels. One of its key advantages is the smooth and consistent surface it offers. MDF is also highly machinable, making it easy to shape and carve. Additionally, it is known for its affordability, stability, and suitability for painting and veneering processes.

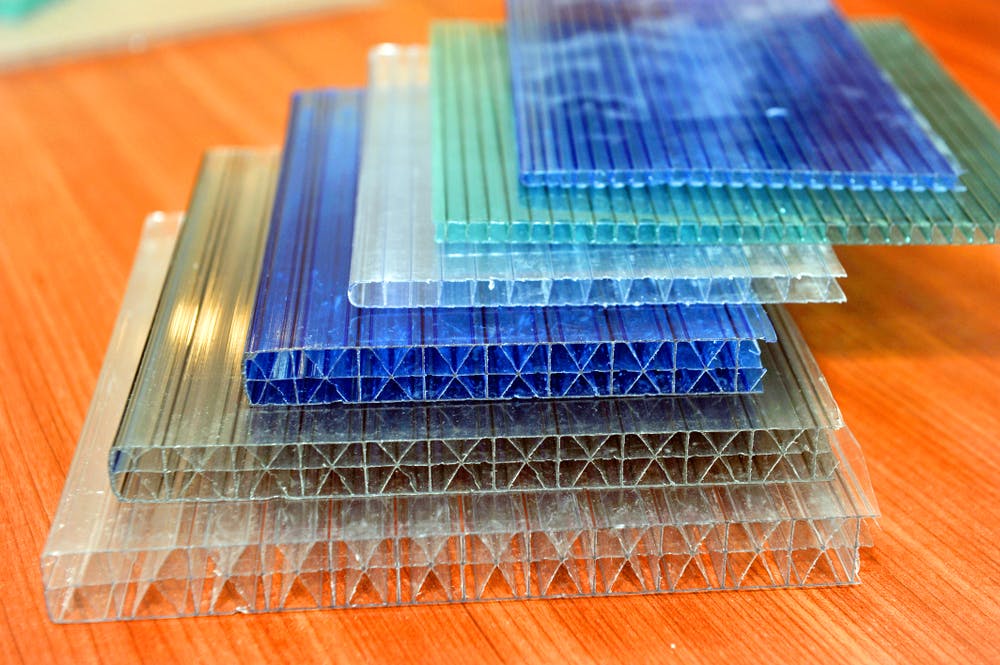

- Polycarbonate: Polycarbonate is a transparent thermoplastic known for its high impact resistance and clarity. It is used in applications such as protective screens, machine guards, lenses, and electronic components. Polycarbonate exhibits excellent impact resistance, high optical clarity, ease of shaping and forming, and good electrical insulation properties.

- Foam: CNC routing is commonly employed in cutting and shaping foam materials such as expanded polystyrene (EPS) and polyurethane foam. Foam is frequently used in packaging, insulation, theatrical props, and architectural modeling.

- UHMW (Ultra-High Molecular Weight Polyethylene): UHMW is a tough and abrasion-resistant thermoplastic with a high molecular weight. It finds applications in bearings, wear strips, conveyor components, and chute liners. UHMW offers excellent abrasion resistance, self-lubrication, low friction, and high impact strength.

- Aluminum: Aluminum is a lightweight metal known for its strength, corrosion resistance, and conductivity. It is commonly used in machine parts, common household hardware, automotive components, and enclosures. Aluminum provides a high strength-to-weight ratio, good thermal and electrical conductivity, and corrosion resistance.

- Brass: Brass is an alloy composed of copper and zinc, known for its attractive appearance and easy machinability. It is used in applications such as decorative items, jewelry, hardware, and musical instruments. Brass also offers good corrosion resistance and antimicrobial properties.

- Composites: CNC routing is used to process composite materials, including fiberglass-reinforced plastic (FRP), carbon-fiber-reinforced plastic (CFRP), and other composite laminates. CFRP exhibits high strength and stiffness, is light for its strength, has excellent fatigue resistance, and low thermal expansion. This material is widely used in the aerospace, automotive, marine, and sports industries.

In need of custom CNC routing services?

Applications of CNC Routing

CNC routing is used in many industries for the production of finished parts and production components. Here are some specific applications of CNC routing:

- Wooden Furniture

- Signage

- Molds for Thermoforming

- Cabinetry and Millwork

- Prototyping and Product Development

- Engraving and Personalization

- Automotive and Aerospace Components

- Wooden Furniture: CNC routing is extensively used in the manufacture of wooden furniture. It enables precise cutting, shaping, and detailing of various wood types, allowing for complex designs, decorative patterns, and smooth edges. CNC routers can produce components like table legs, chair backs, intricate panels, and ornate accents with high accuracy and efficiency.

- Signage: CNC routing is commonly employed in the production of signage for businesses, organizations, and events. It allows for the precise cutting of materials such as wood, plastic, and metal to create custom shapes, letters, logos, and decorative elements. CNC routing can achieve intricate detailing, sharp edges, and consistent results, making it suitable for both indoor and outdoor signage applications.

- Molds for Thermoforming: Thermoforming is a manufacturing process that involves heating a plastic sheet and shaping it over a mold. CNC routing plays a vital role in creating molds for thermoforming. By precisely cutting or carving materials like wood or composite boards, CNC routers can produce molds with intricate shapes and contours, ensuring the accurate and repeatable forming of plastic sheets for various applications like packaging, automotive parts, and medical devices.

- Cabinetry and Millwork: CNC routing is commonly employed in the production of cabinetry and millwork components. It allows for precise cutting, shaping, and detailing of materials like wood, MDF, or plywood, enabling the creation of intricate cabinet doors, drawer fronts, moldings, and decorative panels.

- Prototyping and Product Development: CNC routing is widely utilized for making prototypes during product development. It enables the quick and accurate production of items, allowing designers and engineers to test and refine their designs before moving into full-scale production. CNC routers can produce prototypes from various materials, including plastics, foam, wood, and composites.

- Engraving and Personalization: CNC routing machines equipped with specialized engraving bits can engrave intricate designs, text, logos, or images onto a variety of materials. This makes CNC routing suitable for creating personalized items such as plaques, awards, signs, nameplates, and custom artwork.

- Automotive and Aerospace Components: CNC routing is employed in the manufacturing of automotive and aerospace components. It can be used to shape and trim parts made of materials like aluminum, carbon fiber, plastics, or composites. CNC routers can produce precise cuts and contours required for components such as dashboards, interior panels, exterior trim pieces, and other aircraft parts.

CNC Routing Process at CNC Machining Factory

At Xometry, the following steps are used to turn your designs into a finished product through CNC routing:

- Design the Part: First, start by designing your part using computer-aided design (CAD) software. You will save your work as a vector file. Vector files are commonly saved in the DXF format, but they can also be saved in other formats such as AI, BMP, CDR, DWG, PDF, STL, and SVG. These formats allow for compatibility with different CNC machines and software programs, ensuring seamless transfer and interpretation of the design data.

- Upload CAD File: The second step to getting your design made into physical parts is to upload your CAD file to our website in a compatible format using our instant quoting tool. Once the quote is accepted, we can take the next step.

- G-Code Conversion: After you accept the quote for the job, Xometry will convert the CAD file to G-code. CAM (computer-aided manufacturing) software is utilized to convert vector files into G-code, which is a machine-readable language understood by CNC routing machines. By employing CAM software, the vector design is translated into a series of instructions that precisely guide the CNC router during the cutting process. This ensures that the machine accurately follows the intended tool path and executes the desired cutting, shaping, or engraving operations based on the original vector design. Other processes at Xometry, including laser cutting and other CNC machines, use the same or similar process to our CNC routers.

- CNC Routing Execution: Xometry will then initiate the routing process by running the CNC program. The machine will follow the pre-programmed toolpath, cutting or routing the material according to the design specifications.

- Finishing and Post-Processing: Once the routing process is complete, the finished part may require post-processing steps such as sanding, polishing, or surface treatment to achieve the desired final appearance and quality.

How Do We Account for Kerf?

Accounting for kerf in CNC routing is an important consideration to ensure accurate and precise cutting results. Kerf refers to the width of material that is removed during the cutting process due to the width of the cutting tool. Here are some common methods used to account for kerf in CNC routing:

- Tool Diameter Compensation: One approach is to adjust the tool paths by taking into account the diameter of the cutting tool used. CAM software can be configured to offset the tool paths inward or outward by half of the tool’s diameter. This compensates for the material that will be removed, resulting in the desired final dimensions.

- Test Cuts and Calibration: Another method involves performing test cuts on the same material to determine the actual kerf width produced by the specific CNC routing setup. Runout can occur due to tolerances, damaged equipment, or an uncalibrated CNC routing setup. This causes the kerf to be wider than it should be in theory. By measuring the resulting kerf width, the CAM software can be adjusted accordingly to compensate for the observed kerf, ensuring accurate dimensions in subsequent cuts.

- Material-Specific Kerf Tables: Some CNC routing setups may have pre-determined kerf values for specific materials. These values can be stored in the CAM software as kerf tables or preset, allowing for automatic adjustment of the tool paths based on the selected material. This simplifies the process by eliminating the need for manual kerf measurements or tool diameter calculations.

- Kerf Offset Design: In certain cases, the design itself can be modified to account for kerf. By adjusting the dimensions of the vector file, compensating for the expected kerf width, the CNC routing machine can be programmed to cut precisely to the intended final dimensions. This approach requires careful consideration and knowledge of the specific CNC setup and material properties.