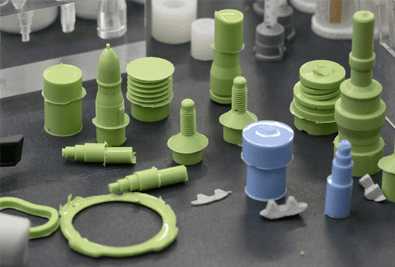

provides exceptional custom mold manufacturing services used in rapidly producing various components for different industries. Our in-house facility is fully equipped with cutting-edge technology to create metal, thermoplastic, and elastomer molds. It’s the ideal service to create a customized solution for your project’s needs.

Our team has years of combined experience in various molding techniques, allowing us to manufacture a mold that fits your unique requirements and specifications. In addition, we collaborate with you every step of the way to create a result that will meet your expectations to reach customer success.

What is Custom Mold?

A mold is used in various molding processes to create a finished product. It’s a hollowed-out form, typically made from aluminum, steel, plastic, rubber, or any other material that can withstand molding.

A molten substance, such as thermoplastics, is poured or forced into a mold, which is then cooled off to harden. With the help of a mold, manufacturers can quickly produce large volume parts and components precisely while ensuring their quality is the same.

Benefits of a mold:

- Greater flexibility

- Create parts with tight tolerances

- Broad design flexibility

- Meets client’s design needs

- Easy to operate and maintain

Custom Mold Manufacturing

Types of Molding Techniques

Injection Molding

Custom injection molding is a manufacturing process where parts are produced in larger volumes with a quick turnaround time. Here, molten materials are injected into the mold. The most common materials used in this molding technique are thermoplastics or thermosetting polymers.

Compression Molding

Two-part mold systems are used to create the finished product in compression molding. The molding material is preheated and placed in an open cavity heated with continuous pressure. After the molding material has been cured, it is removed and cooled off to complete the process.

RTV Molding

RTV or Room Temperature Vulcanization molding is another technique known as resin casting or silicone molding. Custom mold products are created to manufacture products for prototyping or short-run productions quickly.

Rotational Molding

Also known as roto molding, this unique process is ideal for creating hollowed materials without the pressure involved. The custom molds for this manufacturing process are inexpensive since they don’t need to withstand high amounts of pressure.

Custom Molds Made from Reliable Materials

We utilize different metals to create the right custom molds. For instance, rotational, compression, and injection molding techniques require molds made from metal or epoxy. These are expensive but are very durable, especially in full production runs.

Two common materials used in custom mold making:

- Steel: Steel materials are wear-resistant and withstand high pressures, making them durable and ideal for long-term use. It also offers maximum strength for high-volume processes.

- Aluminum: Cheaper than steel, aluminum is an excellent option for those looking for an alternative with the same quality as steel. It’s lightweight and has incredible workability, which allows for more design flexibility.

Choose CNC Machining Factory to Achieve Your Desired Custom Molds

Before the manufacturing stage, CNCMF also offers prototyping and testing of the custom mold to ensure that they meet the characteristics you’re looking for. These are also ideal for instances where durability isn’t a concern. It’s best to start here before choosing a more durable option.

If you have any questions or concerns about our products and services, don’t hesitate to contact us today. You may also request a quote, and we’ll send some estimates for your projects. Reach out now, and we can find a solution for your different production issues.

Why Choose CNCMF as Your Mold-Making Company?

CNC Machining Factory offers tooling and production for the following processes:

- Injection Molding

- Rapid Prototyping and 3D printing

- Cast Urethane and RTV Molding

- Rotational Molding

- CNC Machining

- Lost Wax Investment Casting

- Die Casting

- Stamping and Rubber or Silicone Parts

When you consult with CNCMF about your project, you benefit from our broad experience that allows us to match our extensive capabilities to your individual needs. The initial design consultation is free, and we provide guidance throughout the production process to ensure that you receive exactly the product you’ve envisioned. We also have extensive experience in additional processes such as CNC machining, and we can steer you toward the optimal process or processes for your project.