Rotational molding (BrE: moulding) involves a heated mold which is filled with a charge or shot weight of the material. It is then slowly rotated (usually around two perpendicular axes), causing the softened material to disperse and stick to the walls of the mold forming a hollow part. In order to form an even thickness throughout the part, the mold rotates at all times during the heating phase, and then continues to rotate during the cooling phase to avoid sagging or deformation. The process was applied to plastics in the 1950s but in the early years was little used because it was a slow process restricted to a small number of plastics. Over time, improvements in process control and developments with plastic powders have resulted in increased use.

Rotocasting (also known as rotacasting), by comparison, uses self-curing or UV-curable resins (as opposed to thermoplastics) in an unheated mould, but shares slow rotational speeds in common with rotational molding. This kind of rotocasting should not be confused with centrifugal casting.

Rotational molding machines

Rock and roll machine

This is a specialized machine designed mainly to produce long, narrow parts. Some are of the clamshell type, having one arm, but there are also shuttle-type rock and roll machines, with two arms. Each arm rotates or rolls the mold 360 degrees in one direction and at the same time tips and rocks the mold 45 degrees above or below horizontal in the other direction. Newer machines use forced hot air to heat the mold. These machines are best for large parts that have a large length-to-width ratio. Because of the smaller heating chambers, there is a saving in heating costs compared to biaxial machines.

Clamshell machine

This is a single-arm rotational molding machine. The arm is usually supported by other arms on both ends. The clamshell machine heats and cools the mold in the same chamber. It takes up less space than equivalent shuttle and swing arm rotational molders. It is low in cost compared to the size of products made. It is available in smaller scales for schools interested in prototyping and for high quality models. More than one mold can be attached to the single arm.

Vertical or up & over rotational machine

The loading and unloading area is at the front of the machine between the heating and cooling areas. These machines vary in size between small to medium compared to other rotational machines. Vertical rotational molding machines are energy-efficient, owing to the compactness of their heating and cooling chambers. These machines have the same (or similar) capabilities as the horizontal carousel multi-arm machines, but take up much less space.

Shuttle machine

Most shuttle machines have two arms that move the molds back and forth between the heating chamber and cooling station. The arms are independent of each other and they turn the molds biaxially. In some cases, the shuttle machine has only one arm. This machine moves the mold in a linear direction in and out of heating and cooling chambers. It is low in cost for the size of product produced and the footprint is kept to a minimum compared to other types of machines. It is also available in smaller scale for schools and prototyping.

Swing arm machine

The swing-arm machine can have up to four arms, with a biaxial movement. Each arm is independent from each other as it is not necessary to operate all arms at the same time. Each arm is mounted on a corner of the oven and swings in and out of the oven. On some swing-arm machines, a pair of arms is mounted on the same corner, so that a four-arm machine has two pivot points. These machines are very useful for companies that have long cooling cycles or require a lot of time to demold parts, compared to the cook time. It is much easier to schedule maintenance work or try to run a new mold without interrupting production on the other arms of the machine.

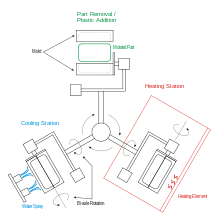

Carousel machine

This is one of the most common biaxial machines in the industry. It can have up to four arms and six stations and comes in a wide range of sizes. The machine comes in two different models, fixed and independent. A fixed-arm carousel consists of three fixed arms that must move together. One arm will be in the heating chamber while another is in the cooling chamber and the third in the loading/reloading area. The fixed-arm carousel works well when identical cycle times are used for each arm. The independent-arm carousel machine is available with three or four arms that can move independently. This allows for different-size molds, with different cycle times and thickness needs.

Production process

The rotational molding process is a high-temperature, low-pressure plastic-forming process that uses heat and biaxial rotation (i.e., angular rotation on two axes) to produce hollow, one-piece parts.Critics of the process point to its long cycle times—only one or two cycles an hour can typically occur, as opposed to other processes such as injection molding, where parts can be made in a few seconds. The process does have distinct advantages. Manufacturing large, hollow parts such as oil tanks is much easier by rotational molding than any other method. Rotational molds are much cheaper than other types of mold. Very little material is wasted using this process, and excess material can often be reused, making it a very economically and environmentally viable manufacturing process.

The rotational molding process consists of four distinct phases:

- Loading a measured quantity of polymer (usually in powder form) into the mold.

- Heating the mold in an oven while it rotates, until all the polymer has melted and adhered to the mold wall. The hollow part should be rotated through two or more axes, rotating at different speeds, in order to avoid the accumulation of polymer powder. The length of time the mold spends in the oven is critical: too long and the polymer will degrade, reducing impact strength. If the mold spends too little time in the oven, the polymer melt may be incomplete. The polymer grains will not have time to fully melt and coalesce on the mold wall, resulting in large bubbles in the polymer. This impairs the mechanical properties of the finished product.

- Cooling the mold, usually by fan. This stage of the cycle can be quite lengthy. The polymer must be cooled so that it solidifies and can be handled safely by the operator. This typically takes tens of minutes. The part will shrink on cooling, coming away from the mold, and facilitating easy removal of the part. The cooling rate must be kept within a certain range. Very rapid cooling (for example, water spray) would result in cooling and shrinking at an uncontrolled rate, producing a warped part.

- Removal of the part.